As a molding process, isostatic pressing technology has the following characteristics compared with conventional molding technology:

a. The product density of isostatic pressing is high, generally 5-15 higher than that of one-way and two-way pressing. The relative density of HIP products can reach 99.8% to 99.09%.

b. The density of the compact is uniform. In compression molding, whether it is unidirectional or bidirectional pressing, there will be uneven density distribution of the green compact. This density change can often reach more than 10% when pressing complex-shaped products. This is due to the frictional resistance between the powder and the steel die. An isostatic fluid medium transmits pressure, equal in all directions. The packing and the powder are compressed roughly the same, the powder and the packing have no relative motion, the frictional resistance between them is very small, and the pressure only decreases slightly. Therefore, the green body density can be considered to be uniform.

c-because the density is uniform. Therefore, the length-diameter ratio of production is not limited, which is conducive to the production of rod-shaped, tubular and slender products.

d. The isostatic pressing process generally does not need to add lubricant to the powder, which not only reduces the pollution to the product, but also simplifies the manufacturing process.

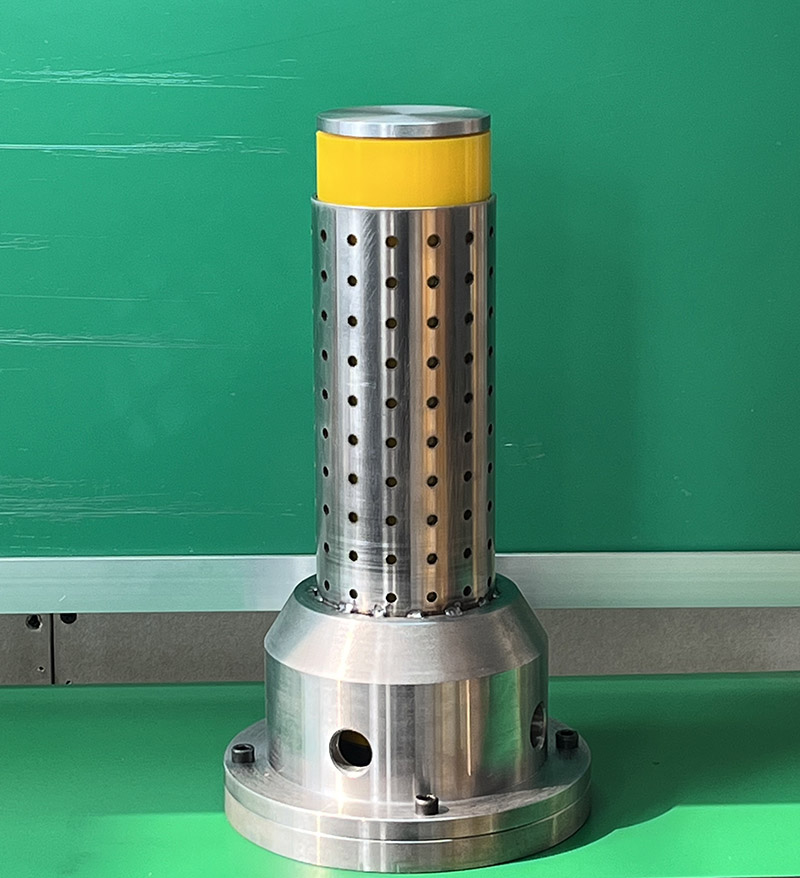

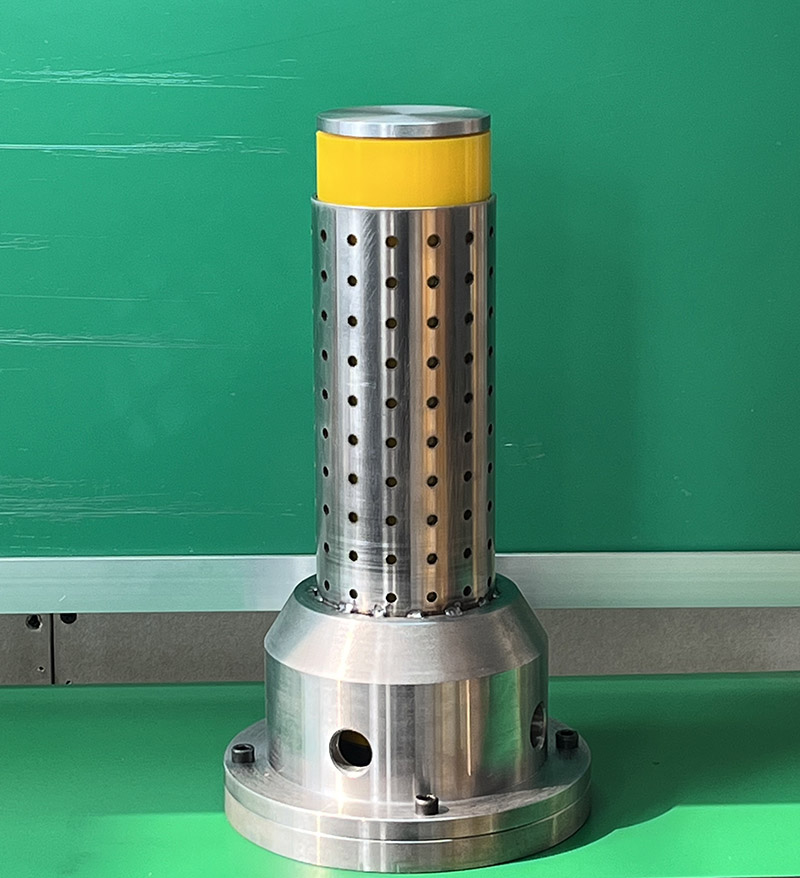

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com