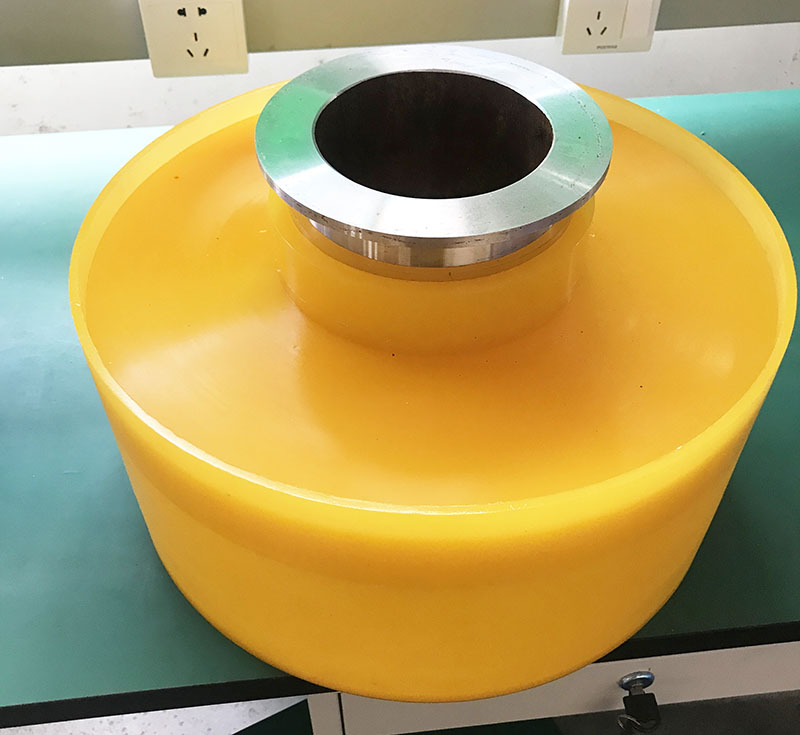

The cold isostatic pressing method is to put the pre-formed green body into the polyurethane isostatic pressing jacket of Hyderland and immerse it in a high pressure liquid to make it bear isotropic pressure, so as to strengthen the density of the green body. Cold isostatic pressing is only to obtain a green body with the highest possible density, which makes the sintering and densification of the green body easier.

Powder metallurgy is a process technology for preparing metal powder or using metal powder (or a mixture of metal powder and non-metal powder) as raw material, after forming and sintering, to manufacture metal materials, composite materials and various types of products. Powder metallurgy is similar to the production of ceramics, both belong to powder sintering technology. Therefore, a series of new powder metallurgy techniques can also be used for the preparation of ceramic materials. Due to the advantages of powder metallurgy technology, it has become the key to solving the problem of new materials and plays a pivotal role in the development of new materials.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com