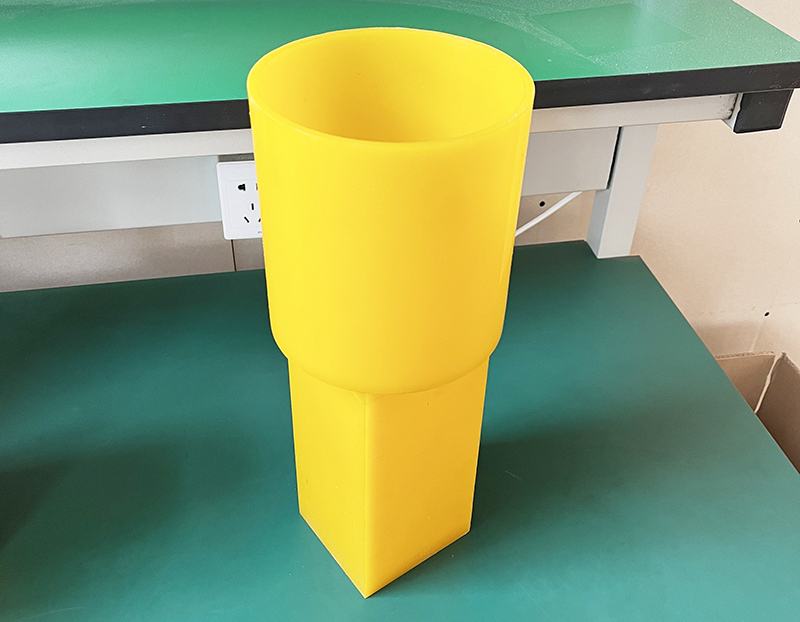

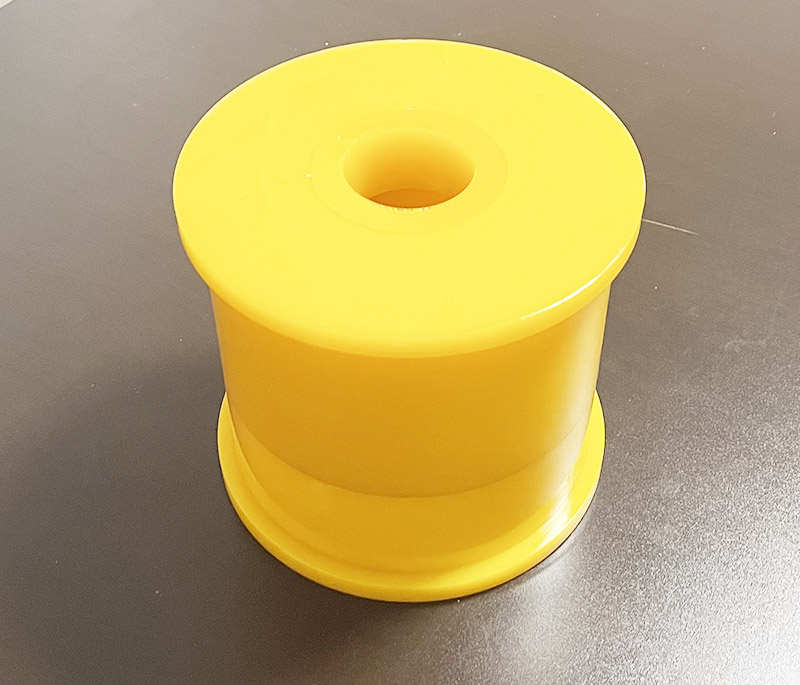

Square,cylindrical,round tube Polyurethane CIP bags, cold isostatic pressing mold for Ceramics, Allo

Categories: Polyurethane CIP bag mold

Application: Square,cylindrical,round tube Polyurethane CIP bags, cold isostatic pressing mold for Ceramics, Alloys, PTPE, Alumina, Graphite

InquiryMain description:

The isostatic pressing mold has a crucial influence on the molding effect of CIP cold, etc. The structure of the isostatic pressing mold determines the molding effect, and the structure of the mold also affects the troublesome effect and production efficiency. The materials of isostatic pressing molds include polyurethane, rubber and silicone, etc. After comparative experiments, isostatic pressing molds made of polyurethane have detailed advantages in all aspects, and are more and more selected. In isostatic pressing, the prototype to be pressed is placed in a high-pressure container, the pressure is uniformly transmitted through the liquid pressure transmission medium, and the various parts are pressurized from all directions, so that the workpiece is formed and the desired effect is achieved. In this pressing process, the workpiece needs to be isolated from the pressure transmission medium, and cannot be in contact with the pressure transmission medium (hydraulic oil) to cause mutual contamination. This requires isostatic pressure molds (sleeves) that can meet hydraulic work.