Cold isostatic pressing molds

Categories: CIP bags, CIP mold

Application: Cold isostatic pressing molds

InquiryMain description:

Cold isostatic pressing molds

Cold isostatic pressing molds

Cold Isostatic Pressing Molds

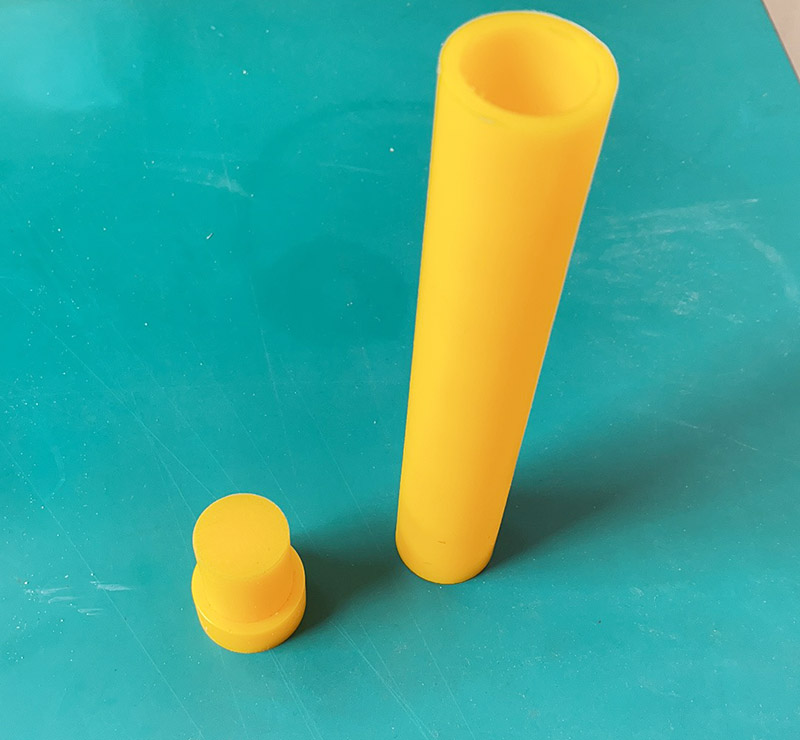

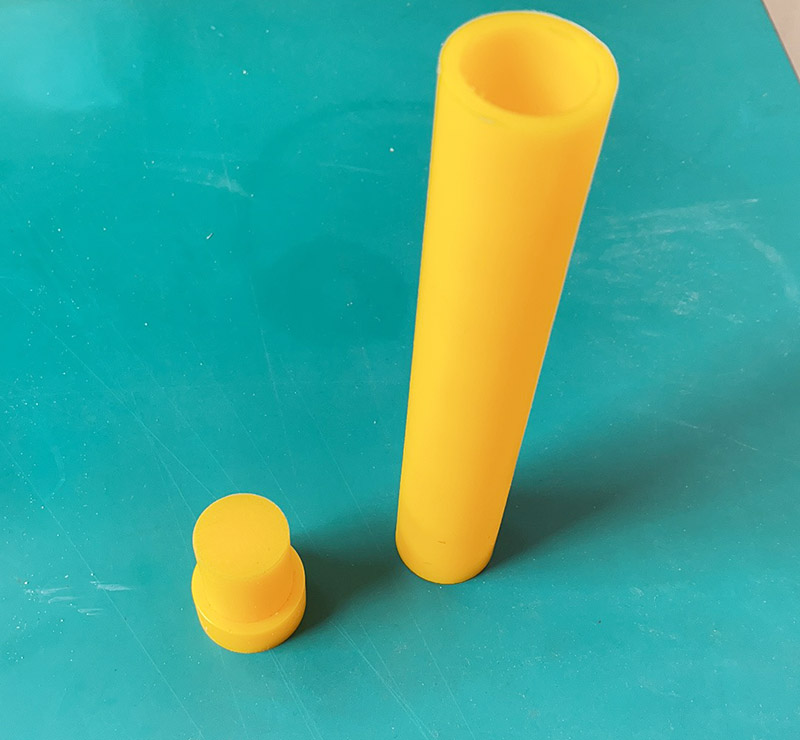

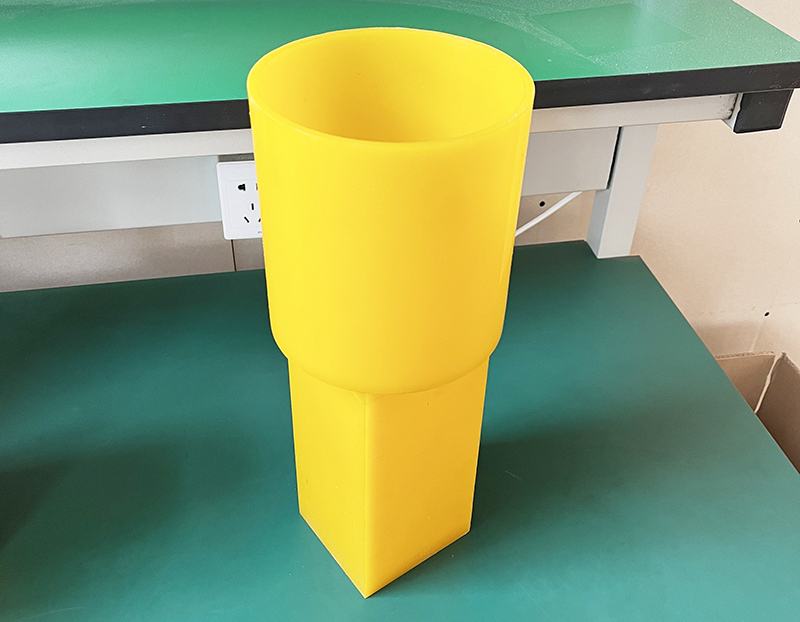

Isostatic pressing molds used in cold isostatic presses. The mainstream molds include polyurethane isostatic pressing molds and rubber isostatic pressing molds. The disadvantage of the rubber isostatic pressing sleeve is that it is not resistant to oil, its physical strength is not as good as the imported polyurethane professional isostatic pressing mold, and its service life is not as good as the latter.

Principle of Isostatic Pressing Isostatic pressing (isostatic pressing) is also called hydrostatic pressing. It is a molding method that utilizes the incompressibility of liquid media and the ability to transmit pressure uniformly. That is, the pressure experienced by a sample in a high-pressure container is the same as the pressure experienced by still water at the same depth, so it is called hydrostatic pressure or Isostatic pressure. The molding process based on this principle is called hydrostatic molding, or isostatic molding.

Types of isostatic pressing Isostatic pressing technology can generally be divided into three types according to the temperature during molding and consolidation: cold isostatic pressing (CIP), warm isostatic pressing (WIP) and hot isostatic pressing (HIP) . Due to the temperature difference during isostatic pressing, the three isostatic pressing technologies use corresponding equipment, pressure media and covering mold materials respectively.

Cold isostatic pressing is divided into two types of isostatic pressing: wet bag method and dry bag method. In wet bag isostatic pressing, the powder is first placed into the molding mold (i.e. the bag), sealed and then placed in a high-pressure cylinder for compression. During the pressing process, the jacket is completely immersed in the liquid and in direct contact with the pressure transmission medium. The wet bag method isostatic pressing has strong applicability and is especially suitable for experimental research and small batch production. It can simultaneously press two or more different shapes of parts in a high-pressure cylinder and produce large and complex-shaped parts. Production process Short and low cost. The mold and blank placement method for wet bag isostatic pressing.

In the dry bag method and isostatic molding, the pressurized rubber mold is placed in the cylinder in advance and is not dared to come out during work. After the powder is loaded into the forming rubber mold, it is put into the pressurized rubber mold together, or the powder is sent from above through the feeding hopper to the pressurized rubber mold. The forming rubber mold is not in contact with the liquid medium, so It’s called the dry bag method. This method can achieve continuous operation, open the upper cover, load materials from the hopper, then close the upper cover and pressurize and form. When discharging the blank, open the upper cover and push the blank out from the top through the push rod at the bottom. The dry bag method has a high degree of automation and a short operating cycle, making it suitable for mass production.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com