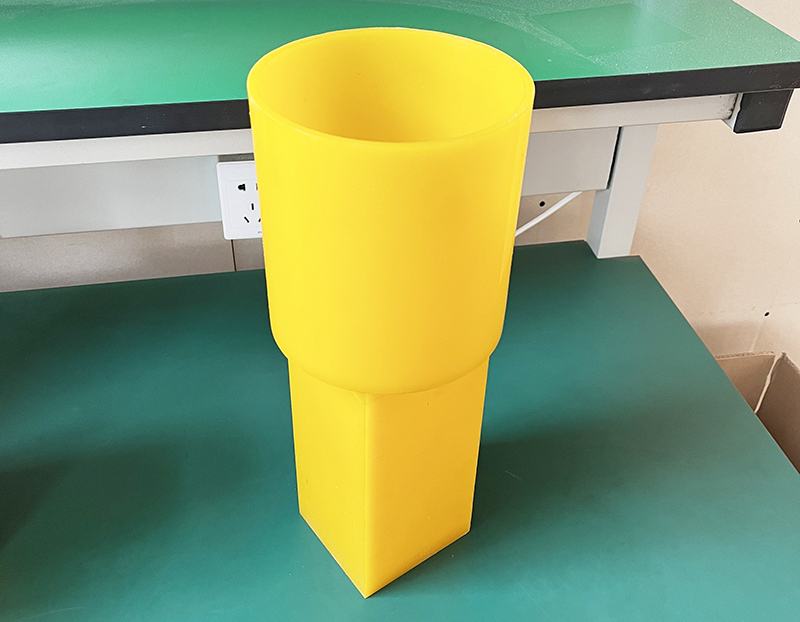

Polyurethane Isostatic Pressing Molds/Moulds/tooling/bags

Categories: Dry bag DIP forming mold

Application: Polyurethane Isostatic Pressing Molds

InquiryMain description:

Polyurethane Isostatic Pressing Molds

Polyurethane Isostatic Pressing Molds

Polyurethane Isostatic Pressing Molds

Molding molds for isostatic presses, isostatic pressing equipment supporting elastomer isostatic pressing rubber sleeve molds, isostatic pressing molding applications, isostatic pressing process products have uniform organizational structure, high density, small sintering shrinkage, and low mold finished product , with outstanding advantages such as high production efficiency and the ability to form products with complex shapes, slender products, large-sized products, and precision-sized products. It is currently a relatively advanced molding process. With its unique advantages, it has begun to replace traditional molding methods, such as ceramic production. Spark plugs, porcelain balls, plungers, vacuum tube shells and other products.

In the isostatic pressing molding process, the properties of the powder, the filling density of the powder in the mold, and the structure of the mold have a great impact on the performance of the molded body, and the structural design of the isostatic molding mold is crucial. In the specific implementation of the isostatic pressing molding process, it is divided into direct isostatic pressing molding and molding-isostatic pressing combined molding process. The direct isostatic pressing molding process is divided into internal pressure method and external pressure method according to the direction of pressure. pressure method. The designs of the molding molds and packages corresponding to these different methods also have their own characteristics.

Direct isostatic pressing is to fill and seal the powder directly into the cavity of the Haideshi isostatic mold, and then directly place it in the liquid medium for pressure molding; while the combined molding and isostatic pressing molding process is to mold it through a rigid mold in advance The blank is taken out, and then the blank is sealed in a plastic bag for isostatic pressing. The internal pressure method and external pressure method in the direct isostatic pressing process are mainly aimed at the forming of hollow tubular green bodies.

The working principle of isostatic pressing technology is to place the pressed green body in a closed high-pressure cavity. The outer surface of the green body is covered with an elastic mold jacket. The high-pressure cavity is filled with high-pressure liquid and a high pressure of hundreds of MPa is applied to the green body. The body is subjected to uniform pressure in all directions and shrinks uniformly. After reaching a predetermined pressure and maintaining it for a certain period of time, a highly densified green body can be obtained. The green body after isostatic pressing has good strength and is easy to machine. The green body has good density and uniformity, which improves the mechanical properties.

Compared with traditional dry pressing molding, isostatic pressing has the following advantages:

1. The density of the green body is higher, generally about 10% higher than that of the dry pressing green body.

2. Able to produce larger or complex shapes.

3. The green body has good strength and is convenient for transportation and direct mechanical processing.

4. The density of the green body is uniform in all directions, the internal stress of the green body is small, and defects such as cracking and delamination of the green body are reduced, and the deformation of the sintered products is small.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com