Isostatic Pressing Molds/Bags for Advanced Ceramic Molding Technology

Isostatic pressing is an advanced ceramic molding technology that is widely used in the molding process of ceramics, glass, metal and other materials. Isostatic pressing mold is the key equipment to realize this technology. Isostatic pressing molds are mainly composed of high-pressure cylinders, molds, sealing rings, pressure gauges and high-pressure pumps. Among them, the mold is the core component, and its structure directly affects the shape and performance of the finished product. During the molding process, the material is put into the mold, and then high-pressure fluid is injected into the mold through a high-pressure pump, so that the material is subject to the same pressure in all directions, thereby forming a finished product with a highly dense structure.

Isostatic pressing mold

Isostatic pressing molds have the following advantages in ceramic isostatic pressing: high molding pressure, which can reach more than 100MPa, giving ceramic materials higher density and better physical properties. The molding temperature is high, which can reach over 1000°C, giving ceramic materials better sintering properties and higher sintering temperatures.

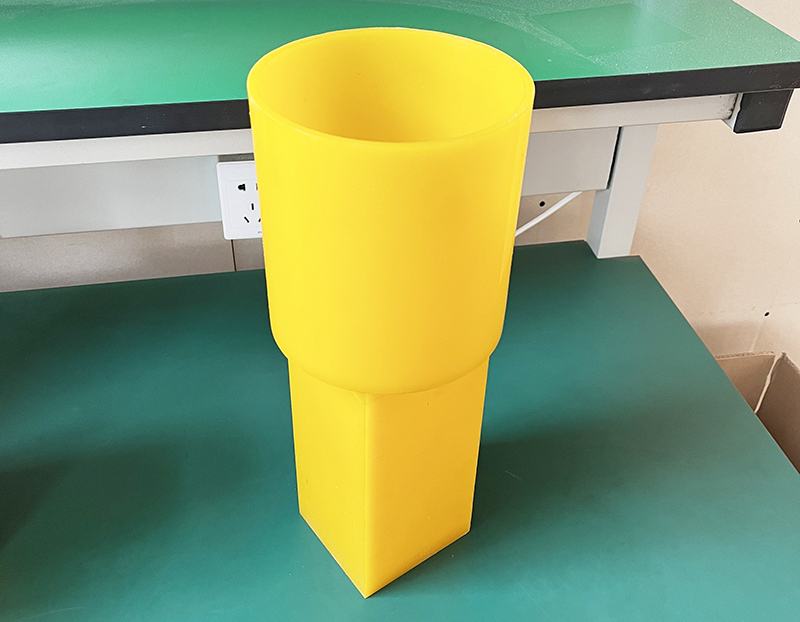

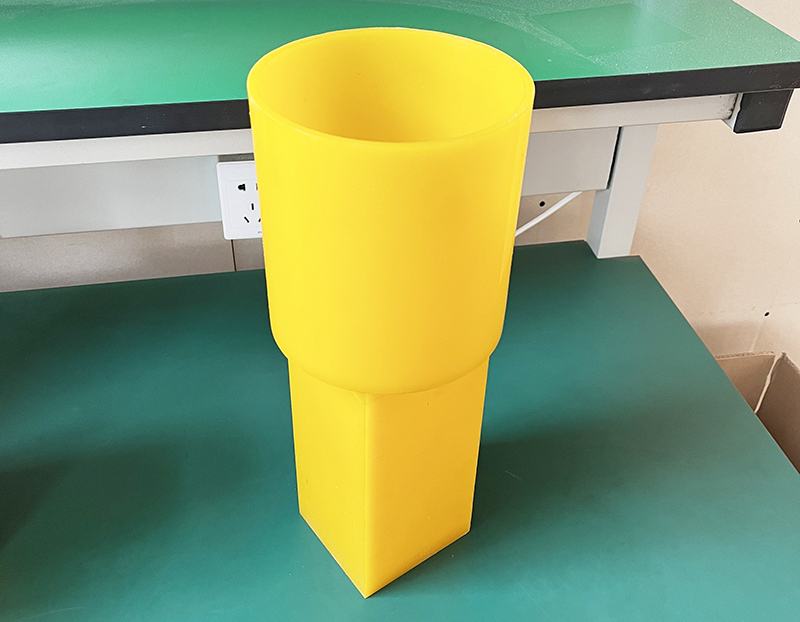

Isostatic pressing bags

The pressure is evenly distributed during the molding process, which avoids the problem of uneven density that occurs in traditional pressing methods. There is no need to use lubricants or binders during the molding process, reducing production costs and environmental pollution. In short, isostatic pressing molds have significant advantages in ceramic isostatic pressing, which can improve the density, physical properties and sintering performance of the finished product, while reducing production costs and environmental pollution.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber mold Plastic mold Polyurethane Product Pu product