Polyurethane Isostatic Pressing Molds for Tungsten and Molybdenum Powder Molding

Isostatic pressing mold is a key equipment specially used for isostatic pressing of tungsten powder and tungsten-molybdenum alloy powder. This kind of mold has high strength, high durability, high precision and excellent elastomer polyurethane rubber mold material, which can meet the molding needs of special materials such as tungsten powder and tungsten-molybdenum alloy powder.

First of all, the tungsten-molybdenum powder isostatic pressing mold is made of high-strength steel or carbide to ensure sufficient strength and stability under high-pressure conditions. At the same time, the design and manufacturing process of the mold strictly follows relevant standards and specifications to ensure its accuracy and reliability.

Secondly, in order to improve the service life and durability of the mold, surface treatment technologies, such as carburizing, quenching, etc., are usually used to enhance the wear resistance and corrosion resistance of the mold. In addition, wear-resistant materials or reinforced structures are used in parts prone to wear, such as mold cores and mold cavities, to reduce wear and extend the service life of the mold.

During the production process, the tungsten-molybdenum powder isostatic pressing mold needs to go through multiple processes of processing and assembly to ensure the accuracy and matching accuracy of each component. At the same time, in order to ensure the stability and reliability of the mold during use, strict inspections and tests are required, including pressure tests, air tightness tests, etc.

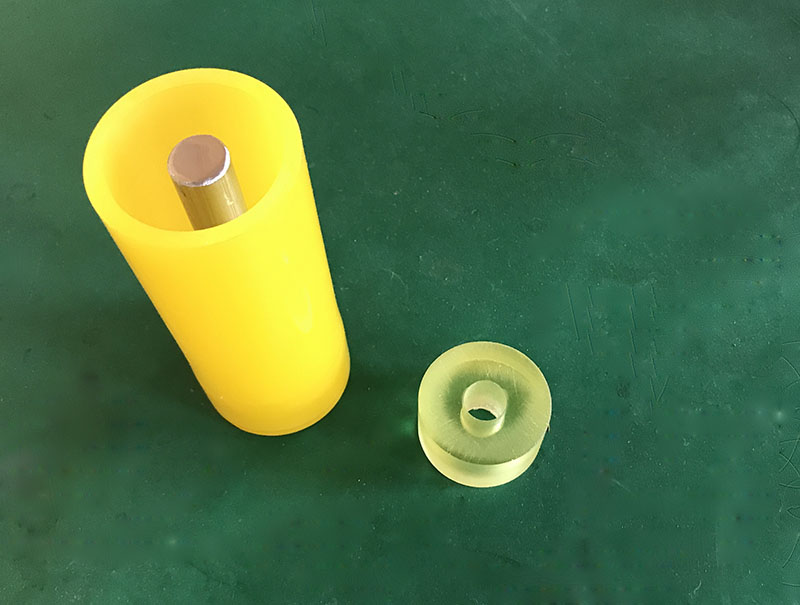

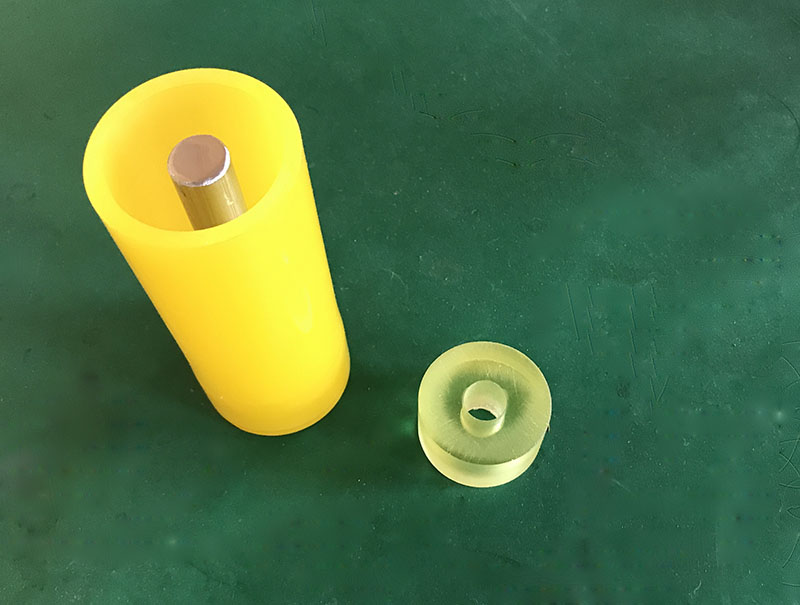

The elastomeric polyurethane rubber mold is an important part of the tungsten-molybdenum powder isostatic pressing mold. This elastomer material has excellent wear resistance, impact resistance and corrosion resistance, and can adapt to the molding needs of various complex shapes and special materials. During the production process, the elastomer polyurethane rubber mold needs to be customized according to actual needs to meet the molding requirements of different products.

In short, the tungsten-molybdenum powder isostatic pressing mold is a high-precision, high-strength, and high-durability equipment that is widely used in the isostatic pressing molding process of tungsten powder, tungsten-molybdenum alloy powder and other special materials. Through reasonable structural design, material selection and manufacturing process, the quality and performance of the mold can be ensured, and production efficiency and product quality can be improved.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber mold Plastic mold Polyurethane Product Pu product