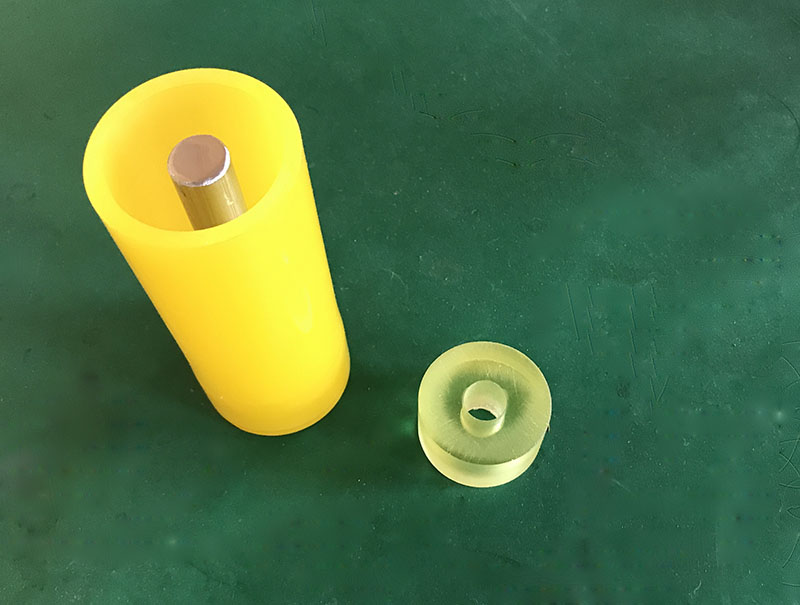

Polyurethane CIP Molds/Bags/Toolings

Categories: Wet bag CIP mold

Application: Polyurethane CIP Molds/Bags/Toolings

InquiryMain description:

Polyurethane CIP Molds/Bags/Toolings

Polyurethane CIP Molds/Bags/Toolings

Polyurethane CIP Molds/Bags/Toolings

CIP is a method of compacting powdered materials into a uniform solid before machining or sintering. It produces high-integrity blanks or preforms that exhibit little distortion or cracking when fired. Its advantages and features include:

Improve production efficiency: CIP is easy to operate, the process is stable, and it can be produced in large quantities, so the production efficiency is high.

Optimize material properties: CIP can make powder materials form dense green bodies under high pressure, with very high density, usually reaching more than 95% of the theoretical density. This results in ceramic materials produced by cold isostatic pressing with higher strength, hardness and wear resistance.

Fine grains: During the CIP process, due to plastic deformation and recrystallization under high pressure, fine grains can be obtained, thereby improving the strength and toughness of the material.

Manufacturing of complex-shaped parts: Cold isostatic pressing technology has good adaptability to the manufacturing of complex-shaped ceramic parts. Through appropriate mold design and pressure control, one-time molding of complex shapes can be achieved, reducing the complexity and cost of subsequent processing.

Complex shapes: By using different mold structures and process parameters, cold isostatic pressing can produce blanks of various complex shapes to meet the needs of different application fields.

Strong controllability: The process parameters of CIP, such as pressure, temperature, holding time, etc., can be precisely controlled to obtain a green body with specific properties and microstructure.

Low material loss: There is no melting during CIP, so there is no chemical reaction and gas phase consumption, and there is almost no material loss.

Energy saving and environmental protection: Since the cold isostatic pressing process does not require high-temperature sintering, it can reduce energy consumption and emissions of waste gas and waste water.

To sum up, this makes cold isostatic pressing technology have broad application prospects in the field of ceramic manufacturing.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com