The Isostatic Pressing Molds for PTFE Molding

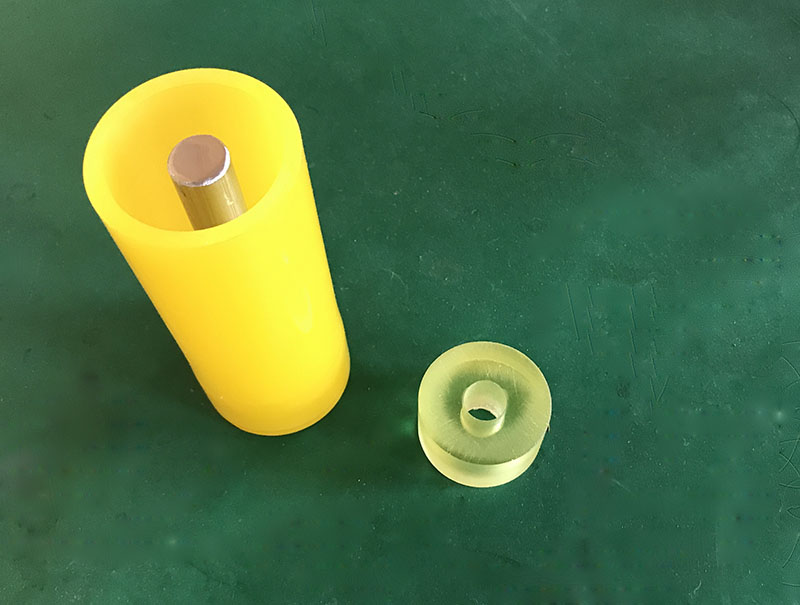

Categories: Polyurethane CIP bag mold

Application: The Isostatic Pressing Molds for PTFE Molding

InquiryMain description:

The Isostatic Pressing Molds for PTFE Molding

The Isostatic Pressing Molds for PTFE Molding

The Isostatic Pressing Molds for PTFE Molding

PTFE static pressure molding process

The process flow of PTFE hydrostatic molding mainly includes powder preparation, pre-pressing, sintering and post-processing

Waiting steps.

1. Powder preparation: First, the PTFE resin needs to be ground and classified to obtain fine PTFE powder. The particle size and distribution of the powder have a great impact on the performance of the final product, so the quality and particle size of the powder need to be strictly controlled during the powder preparation process.

2. Pre-pressing: Put the PTFE powder into the mold, and then apply a certain pressure for pre-pressing. The purpose of pre-pressing is to bring the powder particles together more closely and eliminate gaps and bubbles. The pre-pressure pressure is generally between 20~30MPa, and the time depends on the size and shape of the product.

3. Sintering: Put the pre-pressed PTFE products into a sintering furnace for sintering. Sintering temperature and time are important factors affecting product performance. Generally, the sintering temperature is 340~380℃, and the sintering time is about 1~2 hours. During the sintering process, the PTFE powder particles melt and combine with surrounding particles to form a dense structure.

4. Post-processing: Sintered PTFE products require post-processing, which mainly includes steps such as cooling, trimming and testing. Cooling is to remove the sintered products from the sintering furnace and place them in a natural environment for cooling. Trimming is the cutting and trimming of products to achieve the shape and size required by the design. Testing is to test the appearance and performance of products to ensure that the quality of the products meets the requirements.

Characteristics of PTFE hydrostatic molding

1. Good chemical stability: PTFE has excellent chemical stability and can withstand the erosion of acids, alkalis and most organic solvents.

2. Excellent high temperature resistance: PTFE has a wide operating temperature range and can be used for a long time at temperatures from -200°C to 260°C.

3. Low friction coefficient: PTFE has an extremely low friction coefficient and can achieve good self-lubricating effect under lubrication conditions.

4. Good insulation properties: PTFE has good insulation properties and can maintain stable insulation properties under high voltage and high frequency.

5. Good wear resistance: PTFE has good wear resistance and can be used for a long time under high speed and high load conditions.

The Isostatic Pressing Molds for PTFE Molding

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com