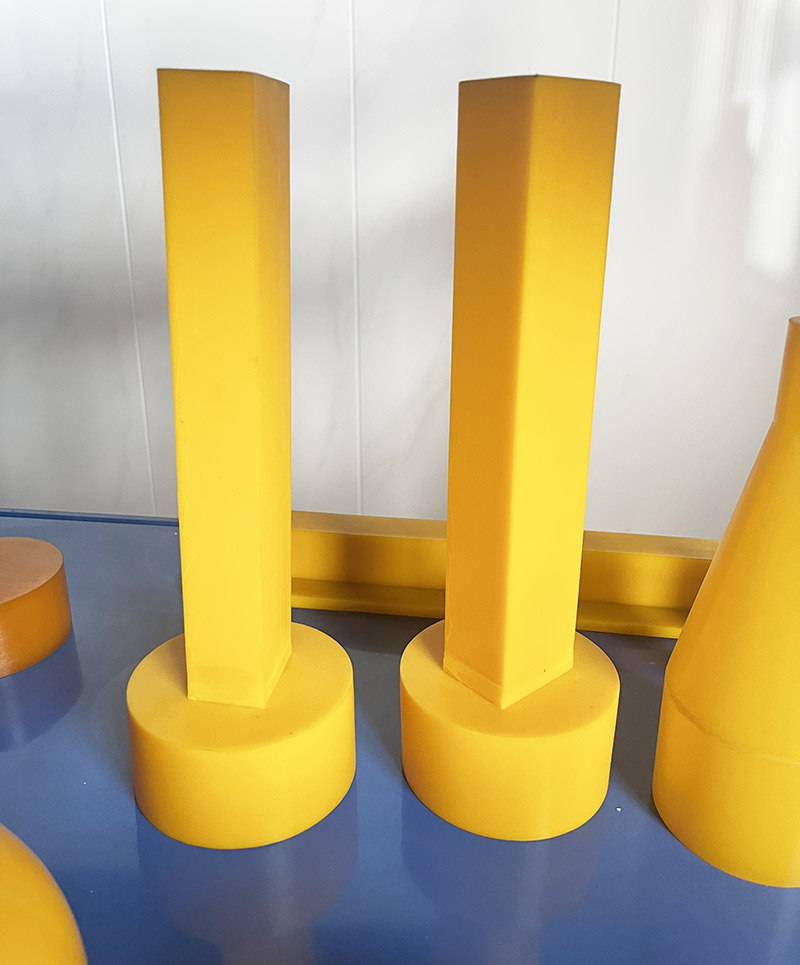

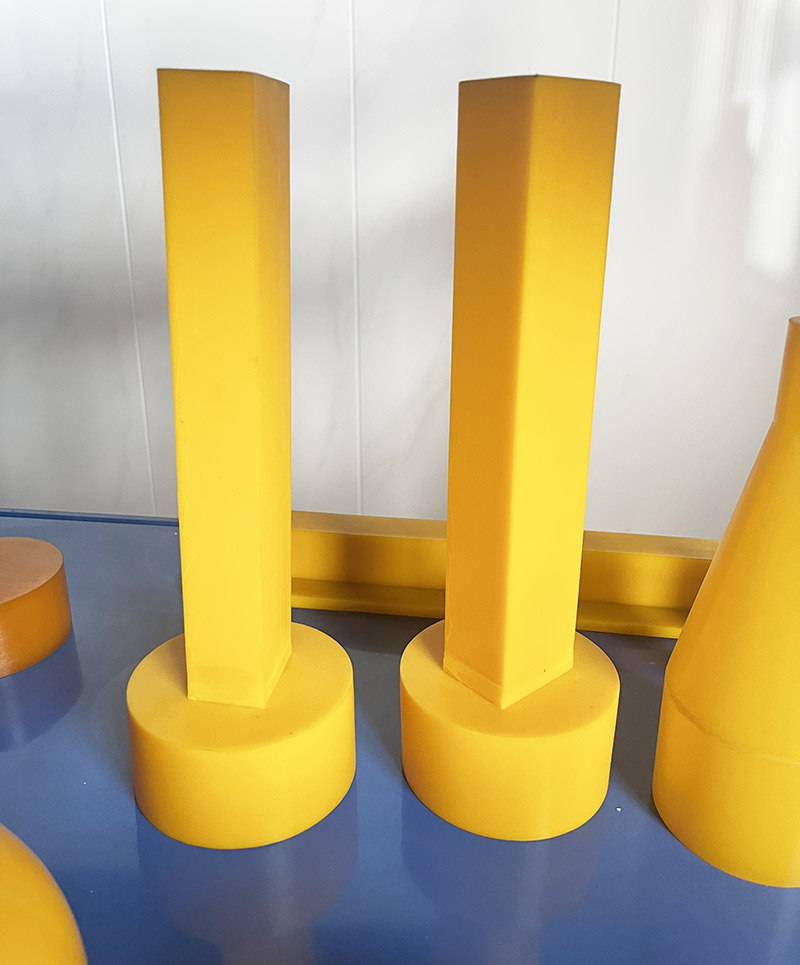

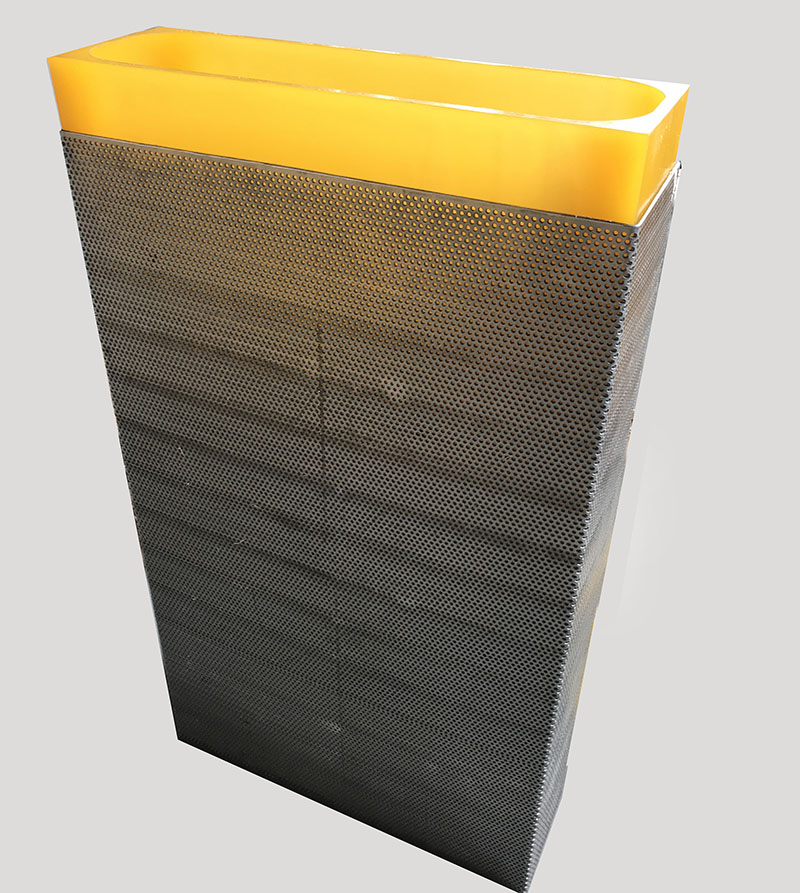

Isostatic Pressing Tooling

Categories: CIP bags, CIP mold

Application: Isostatic Pressing Tooling

InquiryMain description:

Isostatic Pressing Tooling

Isostatic Pressing Tooling

Isostatic Pressing Tooling

It is impossible to prepare large-sized and fine-structured carbon products by molding. To a certain extent, isostatic pressing can overcome the disadvantage of uneven volume density caused by compression molding, greatly reduce the probability of product cracking, and make the production of large-scale and fine-structure products a reality. At the same time, the isostatic pressing process generally does not need to add lubricant to the powder, which not only reduces the pollution to the product, but also simplifies the manufacturing process.

The process of isostatic pressing

The process of isostatic pressing includes 1. When the initial molding pressure is small, the powder particles migrate and re-accumulate. 2. In the middle stage, the pressure is increased, and the powder is partially flowed and crushed. 3. When the pressure is the highest in the later stage, the volume of the powder is compressed, and the pores are discharged, reaching the densification stage.

Features of isostatic pressing

The characteristics of isostatic pressing The principle similar to the isostatic pressing method is axial pressing. Axial compression molding is one-way or two-way pressure pressing, the friction between the powder and the mold is relatively large, and the pressure will cause pressure loss along the pressing direction, making the density of each part of the green body uneven. In isostatic pressing, the pressure transmitted by the liquid medium is equal in all directions. The deformation of the elastic mold when it is under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the force on the green body is uniform, the density distribution is uniform, and the product performance is greatly improved.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com