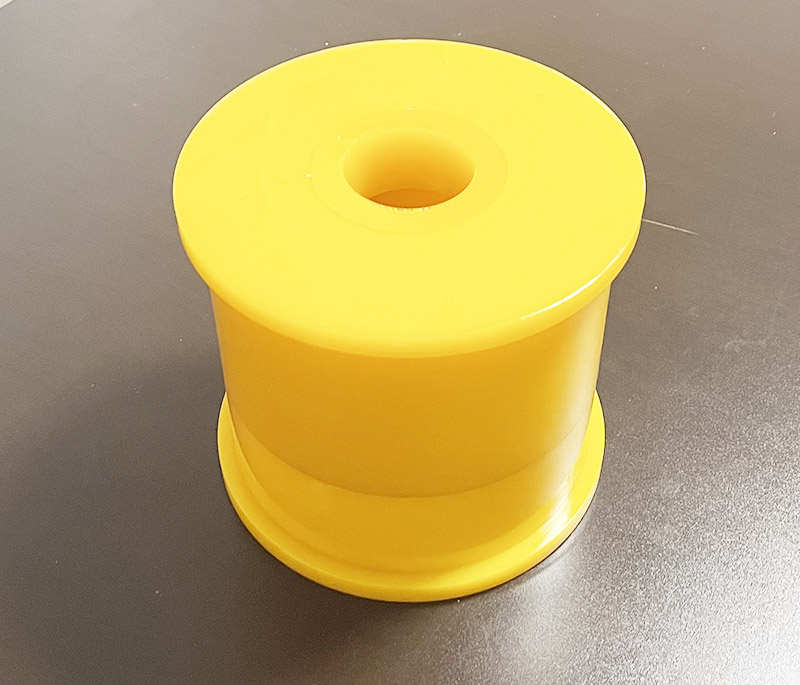

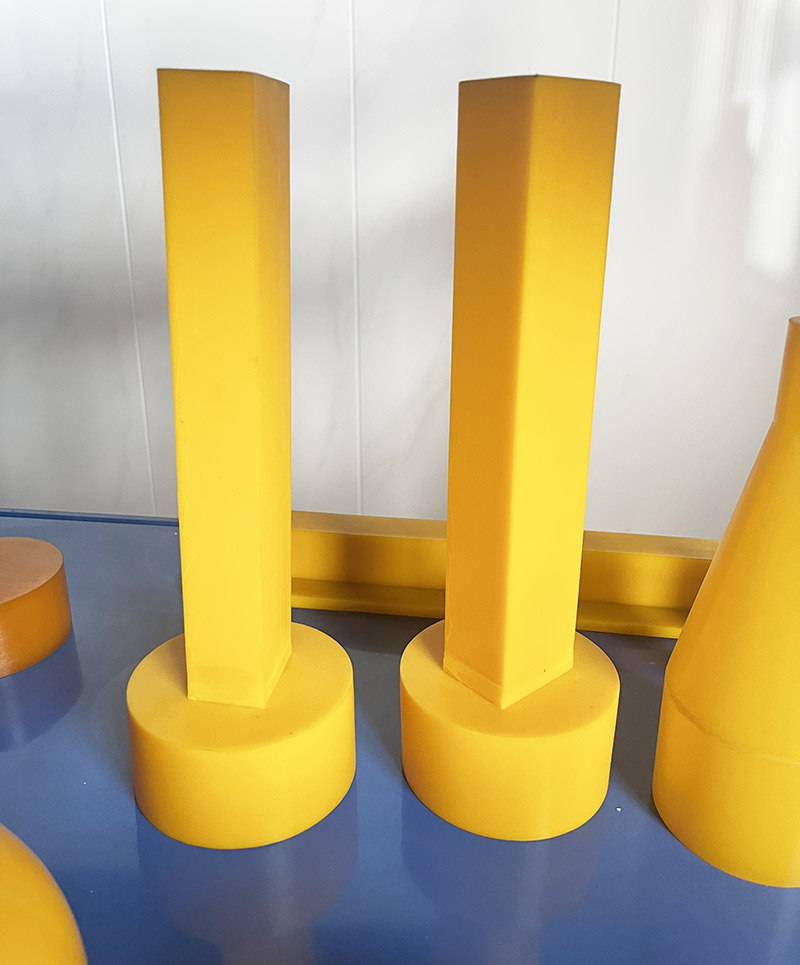

Polyurethane Cold Isostatic Pressing Bags

Categories: DIP mold-dry bag isostatic press

Application: Polyurethane Cold Isostatic Pressing Bags

InquiryMain description:

Polyurethane Cold Isostatic Pressing Bags

Polyurethane Cold Isostatic Pressing Bags

Polyurethane Cold Isostatic Pressing Bags

Cold isostatic pressing molding is a very important ceramic molding technology. It is a method of compressing and molding powder materials by transmitting isotropic pressure through a fluid medium at room temperature. Compared with the conventional molding technology, isostatic pressing has a high density of the green body, which is 5% to 15% higher than that of ordinary compression molding; and the density of the green body is uniform, so it is suitable for cylindrical, cylindrical, etc. In addition, isostatic pressing molding products have excellent performance, so isostatic pressing molding technology has important applications in special ceramics preparation and other fields, and has been successfully applied to some large-scale and complex-shaped ceramic products such as ceramic radome, vacuum arc extinguishing Chamber ceramic shells, thermocouple protection ceramic bushings, alumina or zirconia ceramic tubes for oil drilling, transparent ceramic bushings for high-pressure sodium lamps, high-voltage ceramic insulating tubes, spark plugs, and carbon graphite products.

Isostatic pressing is divided into two processes: dry method and wet method. The wet process powder is put into a plastic bag, placed in a liquid medium, and directly in contact with the liquid. Since the shape and size of the plastic sheath can be changed arbitrarily according to the shape of the product, products of different shapes can be produced, while the dry method is mainly suitable for small-scale production of a single product, so the wet method is more widely used than the dry isostatic pressing. In the isostatic pressing process, the characteristics of the powder, the filling density of the powder in the mold, and the structure of the mold have a great influence on the performance of the formed body, and the structural design of the isostatic pressing mold is very important. In the specific implementation of the isostatic pressing forming process, it is divided into direct isostatic pressing forming and molding-isostatic pressing combined forming process, and the direct isostatic pressing forming process is divided into internal pressure method and external pressure method according to the direction of pressure. pressure method. The designs of the molding dies and wrappers corresponding to these different methods also have their own characteristics.

Cold isostatic pressing technology is at room temperature, usually rubber or plastic is used as the jacket mold material, and liquid is used as the pressure medium. It is mainly used for powder molding to provide blanks for further sintering, forging or hot isostatic pressing processes. The generally used pressure is 100-630MPa.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com