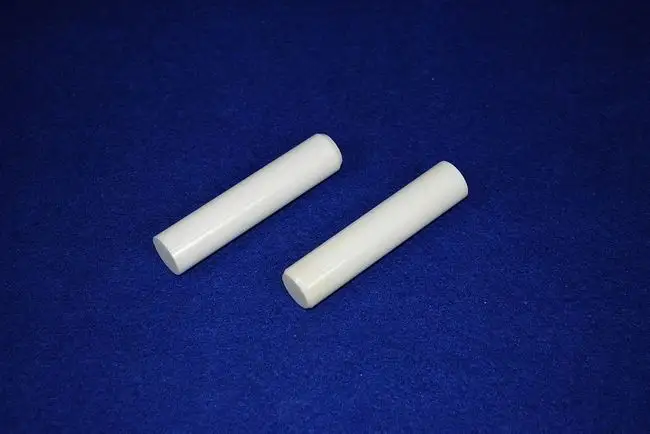

Isostatic Pressing Bags of Zirconia Ceramics

Categories: DIP mold-dry bag isostatic press

Application: Isostatic Pressing Bags of Zirconia Ceramics

InquiryMain description:

Isostatic Pressing Bags of Zirconia Ceramics

Isostatic Pressing Bags of Zirconia Ceramics

Isostatic Pressing Bags of Zirconia Ceramics

Isostatic pressing of zirconia ceramics Isostatic pressing reduces the porosity of the powder mixture to produce a wide variety of shapes made from powder briquettes. These powder mixtures are compacted isostatically, with equal pressure in all directions. According to the production method of isostatic pressing, we can understand that it can be divided into hot isostatic pressing and cold isostatic pressing. Cold isostatic pressing works by applying external pressure to water or oil, which is then transferred to the sealed powder mixture. In addition to obtaining molded bodies with uniform density and defect-free shapes and complex shapes, high pressures of 400MPa to 500MPa can also be achieved, thereby further improving the density of molded bodies and creating favorable conditions for subsequent sintering densification.

Isostatic Pressing Bags

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com