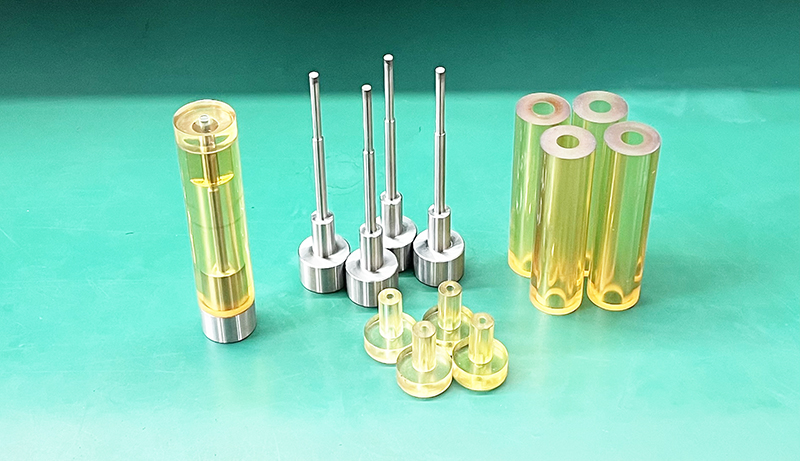

Whole Set of Polyurethane Isostatic Pressing Mold

Categories: DIP mold-dry bag isostatic press

Application: Whole Set of Polyurethane Isostatic Pressing Mold

InquiryMain description:

Whole Set of Polyurethane Isostatic Pressing Mold

Whole Set of Polyurethane Isostatic Pressing Mold

Whole Set of Polyurethane Isostatic Pressing Mold

Isostatic pressing technology is a technology that uses the products in the closed high-pressure container to form under the state of uniform ultra-high pressure in all directions. This technology was first created in the 1930s, and it was mainly used in the powder forming of powder metallurgy in the early stage; in the past 20 years , Isostatic pressing technology has been widely used in ceramic casting, atomic energy, tool manufacturing, plastics, ultra-high pressure food sterilization and graphite, ceramics, permanent magnets, high-voltage electromagnetic porcelain bottles, biopharmaceutical preparation, food preservation, high-performance materials, military industry and other fields .

1. The basic principle of isostatic pressing technology

The working principle of isostatic pressure is Pascal's law: the pressure of the medium (liquid or gas) in a closed container can be transmitted equally in all directions. According to the basic equation of static pressure (Q=Q+Qgh), when the external pressure Q0 of a liquid in a closed container changes, as long as the liquid remains in its original static state, the pressure at any point in the liquid will change changes of the same magnitude. That is to say, in a closed container, the pressure exerted on the still liquid will be transmitted to all points at the same time with equal value. The isostatic pressing technology is to place the sample powder to be pressed in a high-pressure container, and use the incompressible properties of the liquid medium and the properties of uniform pressure transmission to uniformly pressurize the sample from all directions. When the liquid medium is injected through the pressure pump When a pressure vessel is used, according to the principles of fluid mechanics, its pressure is constant and uniformly transmitted to all directions. At this time, the pressure on the powder in the high-pressure container is uniform and consistent in all directions. The method of forming barren powder into a compact body by the above method is called isostatic pressing.

2. Characteristics of isostatic pressing technology

The principle similar to the isostatic pressing method is axial pressing. Axial compression molding is one-way or two-way pressure pressing, the friction between the powder and the mold is relatively large, and the pressure will cause pressure loss along the pressing direction, making the density of each part of the green body uneven. In isostatic pressing, the pressure transmitted by the liquid medium is equal in all directions. The deformation of the elastic mold when it is under the pressure of the liquid medium is transmitted to the powder in the mold, the friction between the powder and the mold wall is small, the green body is evenly stressed, and the product performance is greatly improved with uniform density distribution.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com