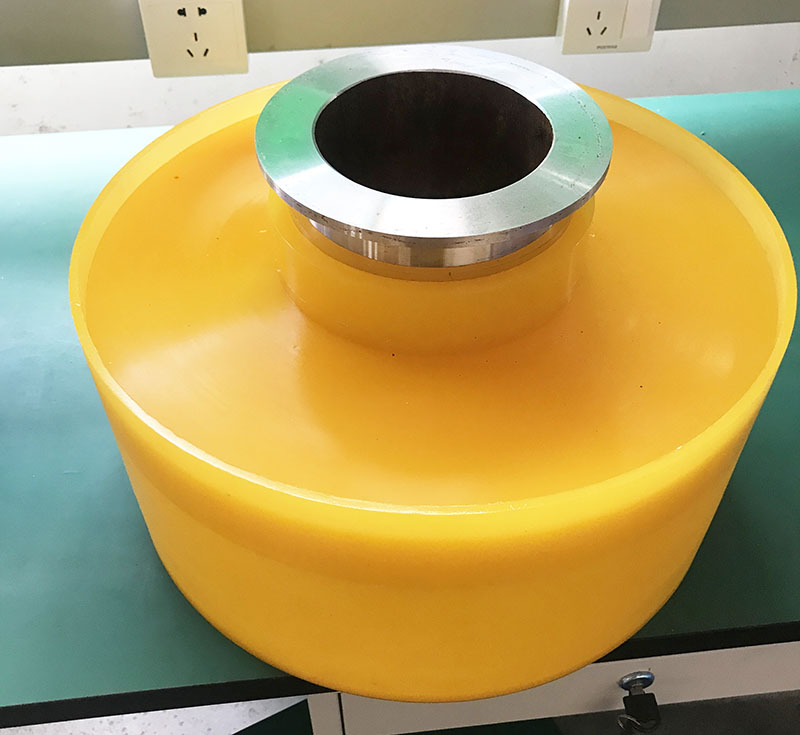

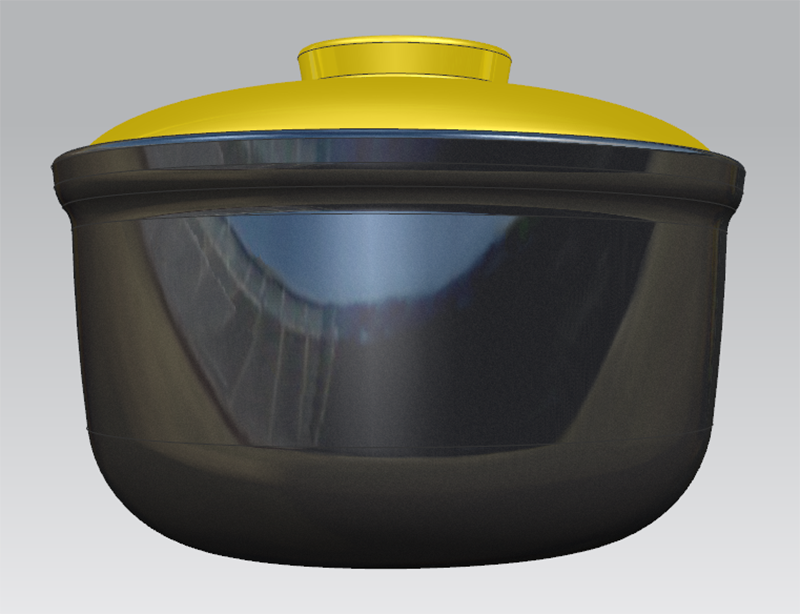

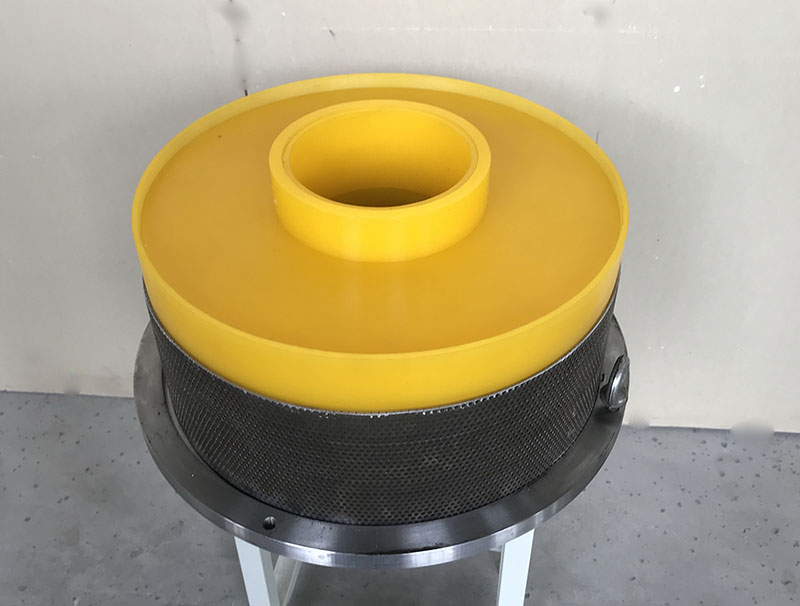

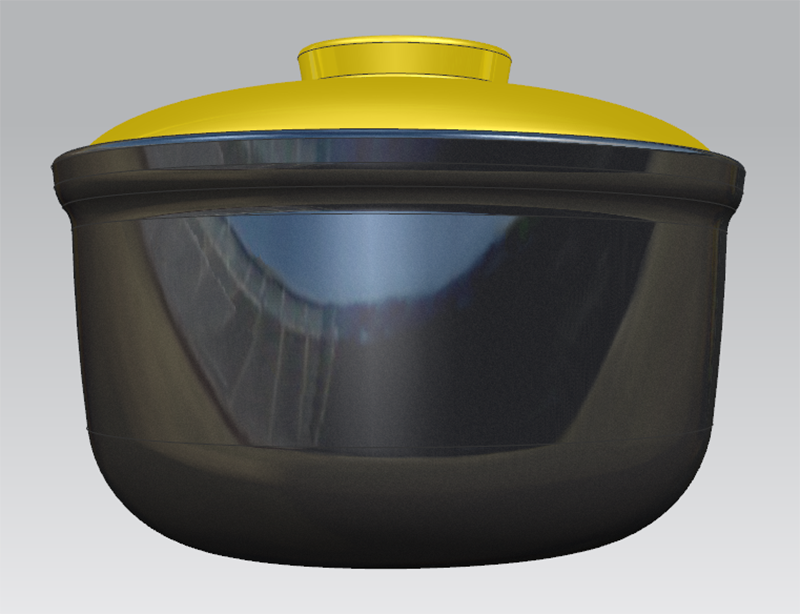

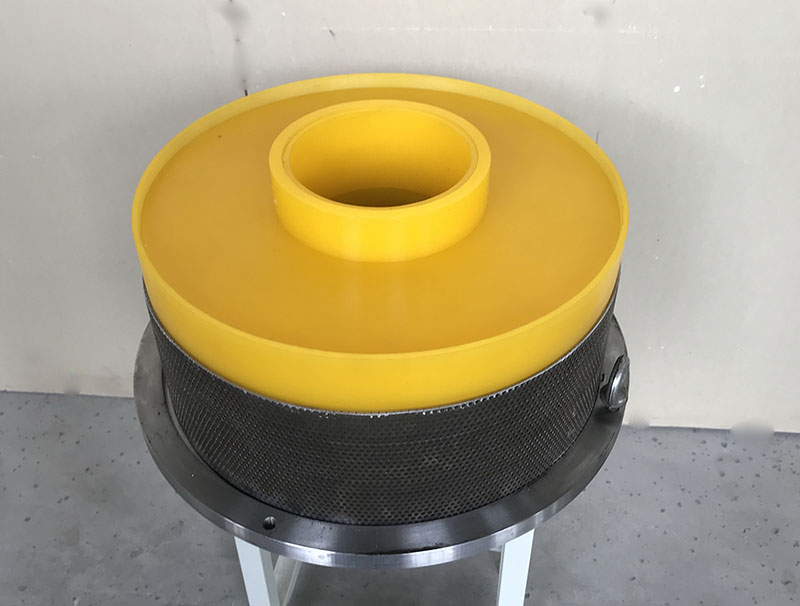

Polyurethane Isostatic Pressing Molds for Isostatic Pressure

The molds for isostatic pressure, polyurethane rubber sleeves for isostatic pressure, design and manufacture of isostatic elastic molds, and customized designs according to working conditions. Elastomer materials include rubber and polyurethane, both of which can be used in the manufacture of isostatic pressing molds. Rubber has some inherent disadvantages and is often used in some occasions with low requirements; polyurethane is divided into many types, which are used in the production of isostatic pressing molds. A raw material developed for the requirements of isostatic pressing, which can withstand high pressure, oil and water resistance for a long time. Ordinary polyurethane materials cannot meet this requirement.

Isostatic sleeve mold, isostatic core metal core, custom-made isostatic fixture, ceramic target isostatic mold design, ceramic target is relatively brittle target, usually ceramic target will be bound to the back plate Used together. In addition to supporting the ceramic target during the sputtering process, the back plate can also play a role in heat transfer during the sputtering process. There are many types of ceramic targets and a wide range of applications, mainly used in the field of microelectronics, displays Applications, storage and other fields. As the basic material for the development of non-metal thin film industry, ceramic targets have achieved unprecedented development.

The characteristics of isostatic pressing: (1) The pressure in the working container of the isostatic pressing brick machine is very high, up to 400MPa or higher, and the pressure in all directions in the container is consistent, so the pressure of each part of the mud is uniform , the density of the molded green body is high and uniform, so that the deformation and shrinkage of the green body during firing are reduced, and the firing cracks will not appear due to the stress caused by the density difference; (2) The molding pressure of the isostatic press can be It is convenient to adjust, and the operation is simple during pressurization, but after pressurization, decompression and post-processing of the green body are required; (3) The molding mold is made of rubber or plastic, which is easy to manufacture, low in cost, and can be used repeatedly; (4) Temporary binders may not be used or used less in the blank; (5) The isostatic pressing method can suppress large and slender products with complex shapes that cannot be formed by general molding methods.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold