Design and Product Full Set of Isostatic Pressing Mold/Bag

Categories: Wet bag CIP mold

Application: Design and Product Full Set of Isostatic Pressing Mold/Bag

InquiryMain description:

Design and Product Full Set of Isostatic Pressing Mold/Bag

Design and Product Full Set of Isostatic Pressing Mold/Bag

Design and Product Full Set of Isostatic Pressing Mold/Bag

Isostatic pressing is to place the sample to be pressed in a high-pressure container, and use the incompressible properties of the liquid medium and the properties of uniform pressure transmission to uniformly pressurize the sample from all directions. When the liquid medium is injected into the pressure vessel through the pressure pump , according to the principle of fluid mechanics, the pressure is constant and uniformly transmitted to all directions. At this time, the pressure on the powder in the high-pressure container is uniform and consistent in all directions. The method of forming a dense body from barren powder through the above method is called isostatic pressing.

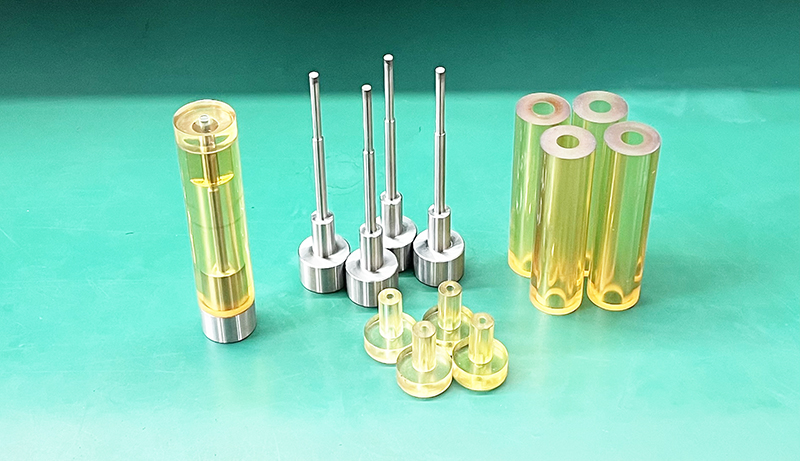

Isostatic pressing mold, dry isostatic pressing ceramics, isostatic graphite, CIP forming rubber sleeve mold for isostatic pressing alloy products, complete set of design, complex shape isostatic forming mold, precision forming mold, tooling fixture. Sealing structure design, precise molding design, selection of elastic mold hardness, and fixture design ensure molding accuracy. The isostatic rubber sleeve mold made of special polyurethane material has rolling advantages in terms of performance and cost performance! The polyurethane polymer material specially developed for isostatic pressing molds has good plasticity, good elasticity, oil resistance, water resistance and oxidation resistance. nice features. Embodied in isostatic pressing production, it means precise molding, smooth surface and long service life. According to the usage, there are targeted solutions, including design, manufacturing of rubber sleeves, tooling, lifting and other fixtures. Of course, the so-called isostatic pressing molds that are crudely manufactured by ordinary polyurethane products companies with conventional polyurethane materials cannot realize those advantages. Isostatic pressing is to place the sample to be pressed in a high-pressure container, and use the incompressible properties of the liquid medium and the properties of uniform pressure transmission to uniformly pressurize the sample from all directions. When the liquid medium is injected into the pressure vessel through the pressure pump , according to the principle of fluid mechanics, the pressure is constant and uniformly transmitted to all directions. At this time, the pressure on the powder in the high-pressure container is uniform and consistent in all directions. The method of forming a dense body from barren powder through the above method is called isostatic pressing.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com