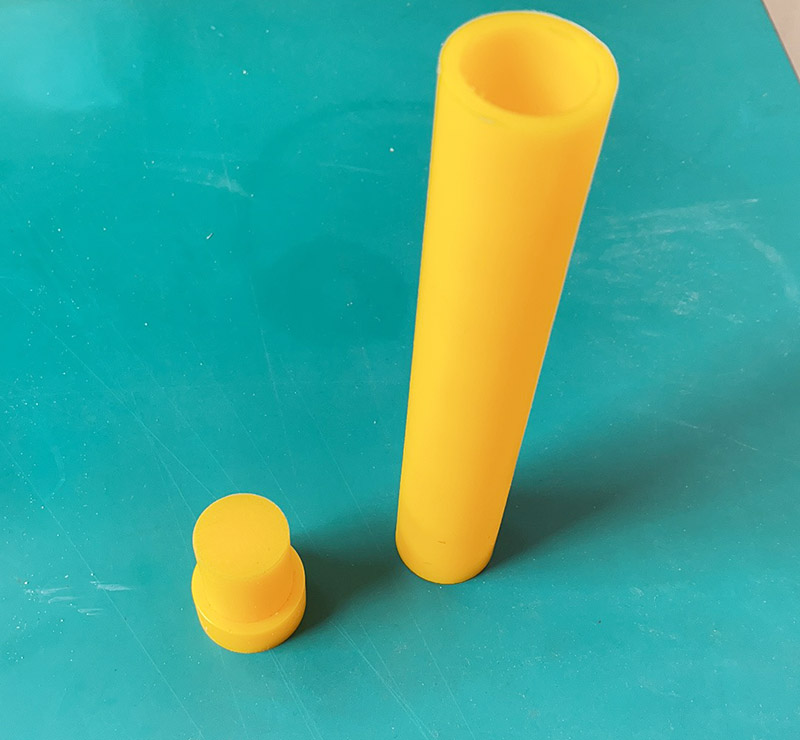

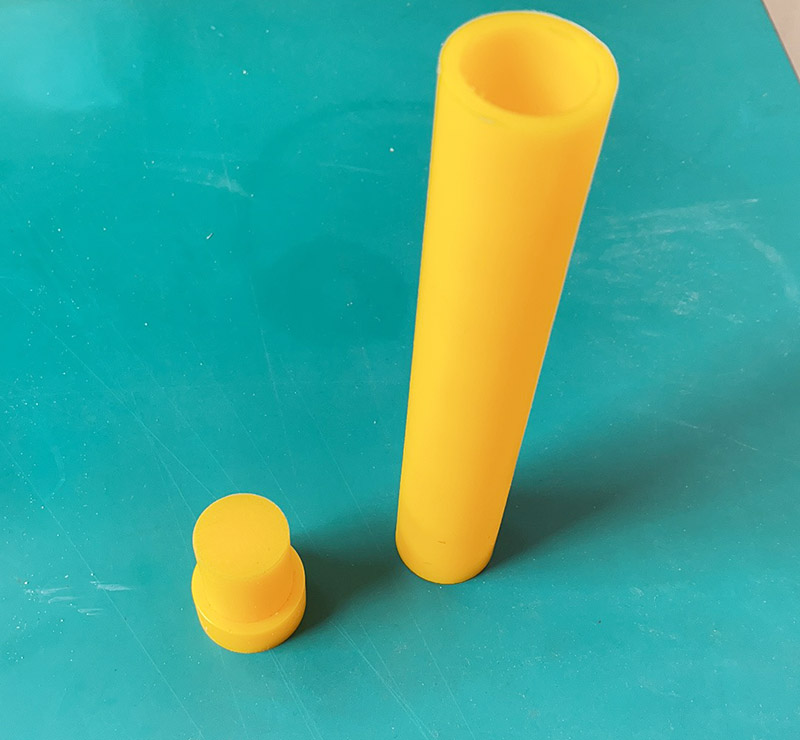

Design and Manufacture Isostatic Pressing Molds/Bags

Categories: CIP powder forming bag mold

Application: Design and Manufacture Isostatic Pressing Molds/Bags

InquiryMain description:

Design and Manufacture Isostatic Pressing Molds/Bags

Design and Manufacture Isostatic Pressing Molds/Bags

Design and Manufacture Isostatic Pressing Molds/Bags

Low-cost isostatic pressing rubber molds are used for isostatic pressing molding with general requirements. Usually, there is a large margin left on the compact, which is used for isostatic pressing molding of products with low size requirements, or after pressing into a green body for processing into various shapes. Polyurethane isostatic pressing molds are used for precise molding. The material is non-stick, has good rebound, accurate size, easy to maintain shape, and adjustable hardness. It is used for isostatic pressing of new materials, precious metals and special-shaped parts.

In the isostatic pressing process, the characteristics of the powder, the filling density of the powder in the mold, and the structure of the mold have a great influence on the performance of the formed body, and the structural design of the isostatic pressing mold is very important. In the specific implementation of the isostatic pressing forming process, it is divided into direct isostatic pressing forming and molding-isostatic pressing combined forming process, and the direct isostatic pressing forming process is divided into internal pressure method and external pressure method according to the direction of pressure. pressure method. The designs of the molding dies and wrappers corresponding to these different methods also have their own characteristics.

When designing an isostatic pressing mold, various aspects such as sealing, molding, demoulding and service life should be considered. Polyurethane isostatic pressing molds have high resilience, fatigue resistance, low deformation rate, and easy demoulding. They are used in dry bag and wet isostatic presses to press ceramic product blanks, graphite products, hard alloys and other non-standard powder molding. The oxidation resistance of rubber is low, the service life is not as good as that of polyurethane, and the molding effect is also inferior to that of polyurethane isostatic pressing molds.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com