Isostatic Pressing Molds for Transparent Ceramics

Categories: DIP mold-dry bag isostatic press

Application: Isostatic Pressing Molds for Transparent Ceramics

InquiryMain description:

Isostatic Pressing Molds for Transparent Ceramics

Isostatic Pressing Molds for Transparent Ceramics

Isostatic Pressing Molds for Transparent Ceramics

The so-called transparent ceramics are ceramics that can transmit visible light. Ordinary polycrystalline ceramic materials are generally opaque due to their anisotropy, extinction factors between grains of the low-symmetry crystal structure system, and internal impurities and pores that absorb and scatter visible light.

The most commonly used molding methods for transparent ceramics are dry pressing and isostatic pressing.

(1) Dry pressing

Dry pressing molding is a simple and easy molding method, and it is also a commonly used molding method at present. The main process of dry pressing is to put the powder into the mold after ball milling and granulation (you can add a certain solvent, usually water or organic solvent), and apply a certain pressure to make the powder form a certain shape and strength. Ceramic green body. Dry pressing has the advantages of simple operation, low cost, and high production efficiency, and is suitable for producing ceramic samples with small size and simple shape.

(2) cold isostatic pressing

The specific method of cold isostatic pressing is to put the powder into a rubber bag, place it in a steel mold, and apply pressure to the powder from all directions to form it. This molding method can evenly apply pressure to the powder, and overcome the disadvantage of insufficient uniform pressure during the dry pressing molding process.

Cold isostatic pressing can be divided into three methods: dry bag method, wet bag method and balanced pressing method. The above picture shows the schematic diagram of dry bag method and wet bag method. In the dry bag method, the pressurized mold is fixed inside the oil cylinder. This method is easy to operate and has a short cycle, which is suitable for mass production. In the wet bag method, the mold is separated from the pressure cylinder, and this molding method can obtain ceramic green bodies with complex shapes. The balanced pressing method is basically the same as the dry pressing method.

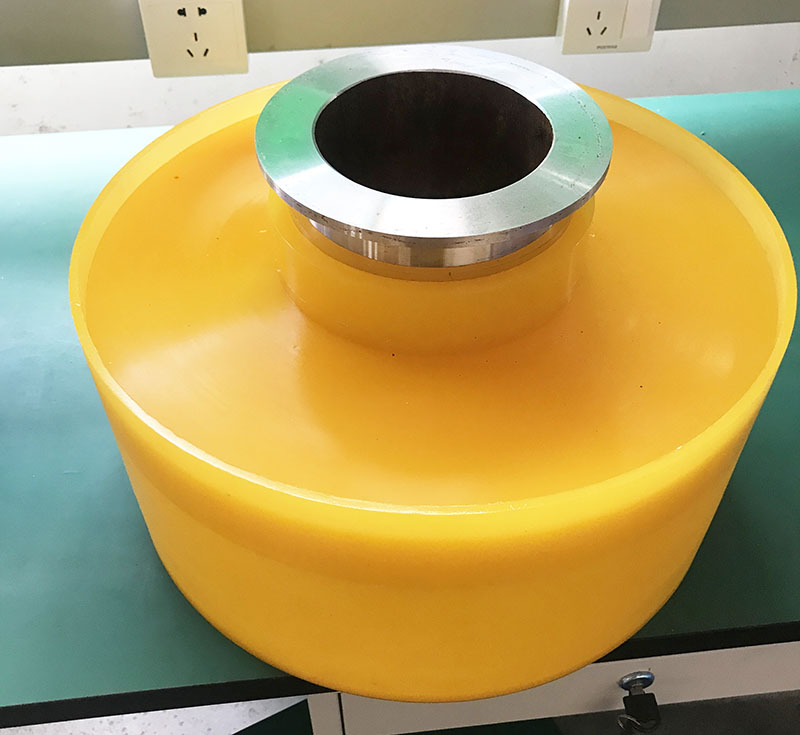

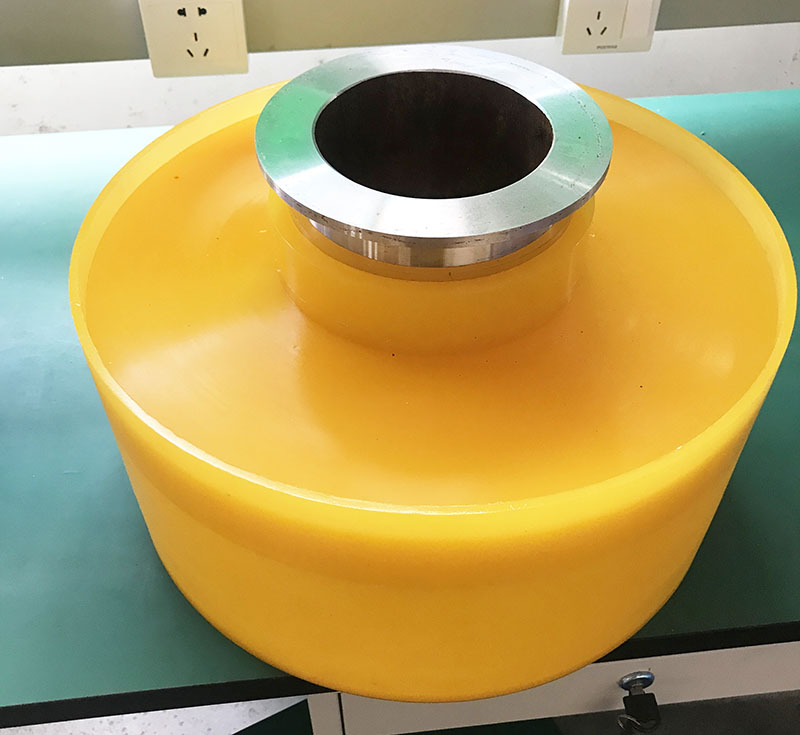

Polyurethane Isostatic Pressing Molds

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com