The Polyurethane Isostatic Pressing Bags for Isostatic Pressing Battery

The large-scale application of lithium batteries has completely changed the pattern of the electronics industry and brought revolutionary changes to the development of electric vehicles and hybrid vehicles. At the same time, the electrification transformation initiated by the automotive and aviation fields has also accelerated the continuous development of solid-state battery technology. The solid-state battery adopts a solid-state electrolyte embedded between the anode and the cathode in the form of a sandwich, which has more stable chemical properties and energy storage capacity, and at the same time charges faster and has a longer life, avoiding the loss of personnel and equipment caused by short-circuit thermal runaway of lithium-ion batteries risks of. Therefore, the commercial-scale production of solid-state batteries has become a primary goal for electric vehicle manufacturers and the aerospace industry.

What is a solid state battery?

Batteries consist of four main components: current collector, anode (negative electrode), cathode (positive electrode), and electrolyte. Lithium-ion batteries, which contain a liquid electrolyte, have revolutionized the electronics industry in recent decades and are now used in electric and hybrid vehicles. However, if a lithium-ion battery is short-circuited, it can generate heat and fumes, putting people and equipment at risk. Solid-state batteries use a solid-state electrolyte embedded between the anode and cathode in the form of a sandwich, which has more stable chemical properties and energy storage capabilities. This is where the pressure is applied, to consolidate the monolithic cells and ensure effective interfacial contact between the active cell components.

The principle and application prospect of solid state battery produced by isostatic pressing technology

Experiments have shown that the production of solid-state batteries requires the application of extremely high pressures (from 5,000 to 6,000 bar // 72,518 to 87,022 psi) combined with high temperatures (up to 200°C // 392°F) to densify them to remove pores and voids to ensure sufficient interface contact between active components.

Isostatic pressing is a proven technique for powder consolidation and densification of solid materials. Metals, ceramics, composites and polymers are all densified by isostatic pressing. Isostatic pressing has been proven to eliminate pores and voids in monolithic cells and improve contact between component interfaces in solid-state monolithic cells, resulting in enhanced conductivity, higher energy density (Wh/l) and reduced volume during operation The enhanced conductivity will endow the battery with more excellent electrochemical performance, which is the key technology to solve the commercial scale production of solid-state batteries. In addition to this, isostatic pressing is also used for the lamination of individual components, which are indispensable for driving the development of future battery technology. Common application areas for this technology include cathodes, anodes, composites, ceramics, carbon-based materials, and solid-state electrolyte compaction.

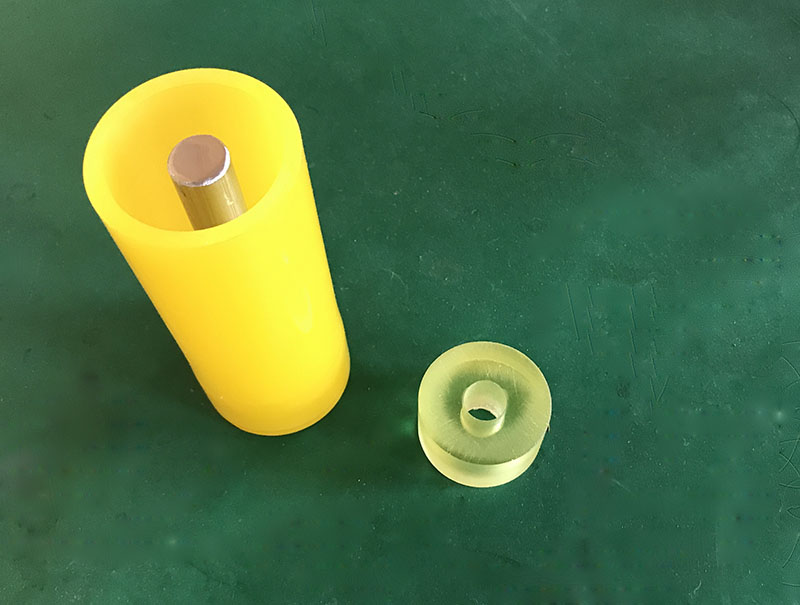

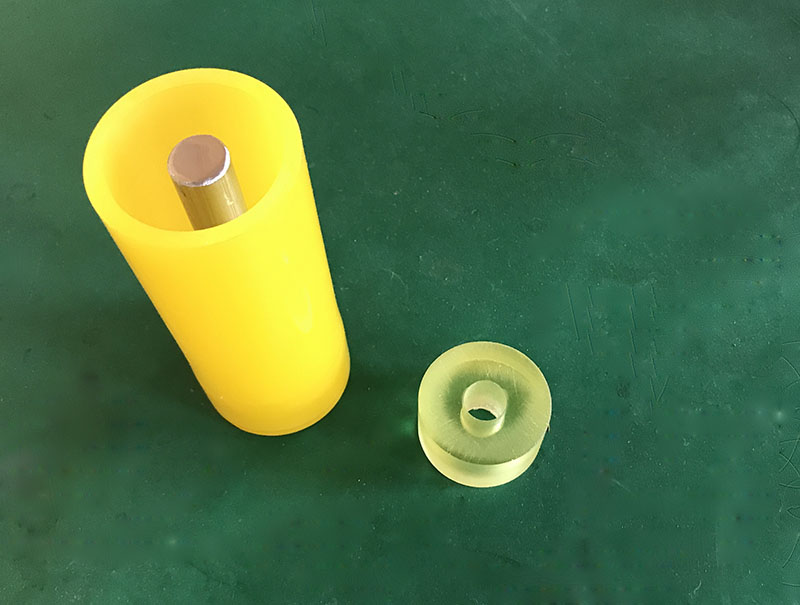

A Sample of Isostatic Pressing Bags

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold