Design and Product Isostatic Pressing Mold

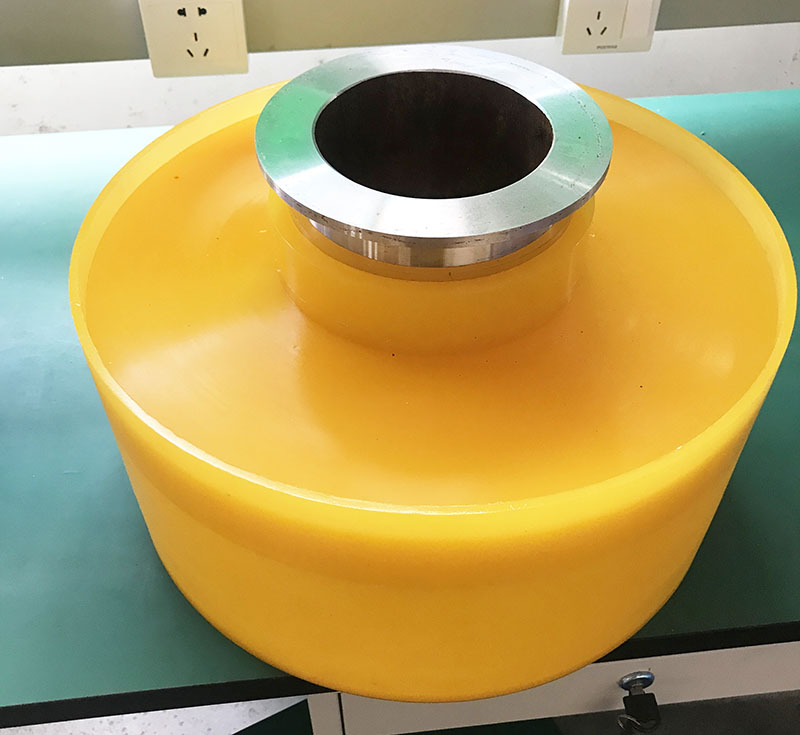

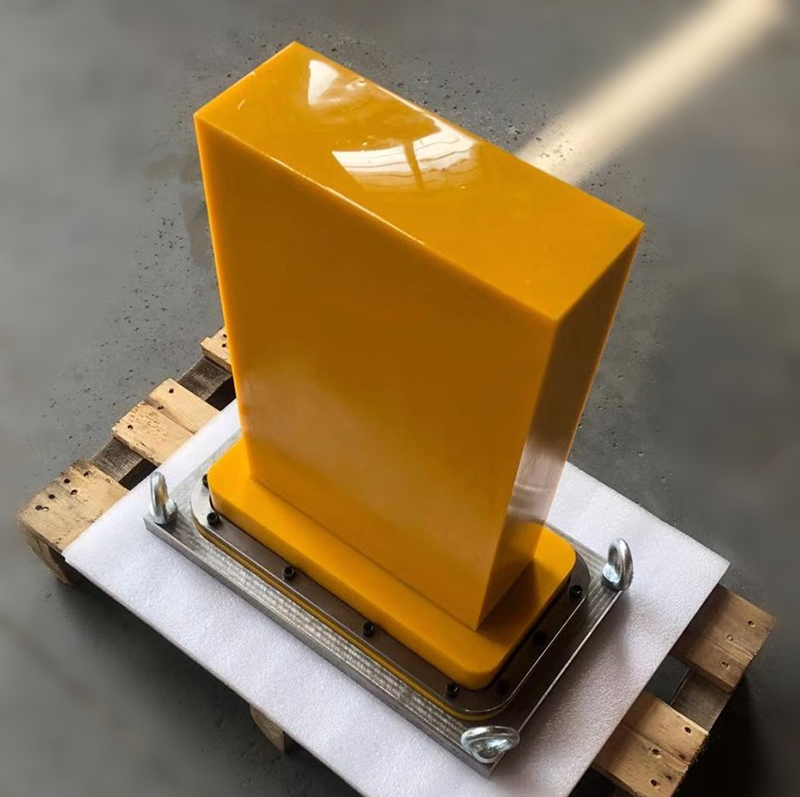

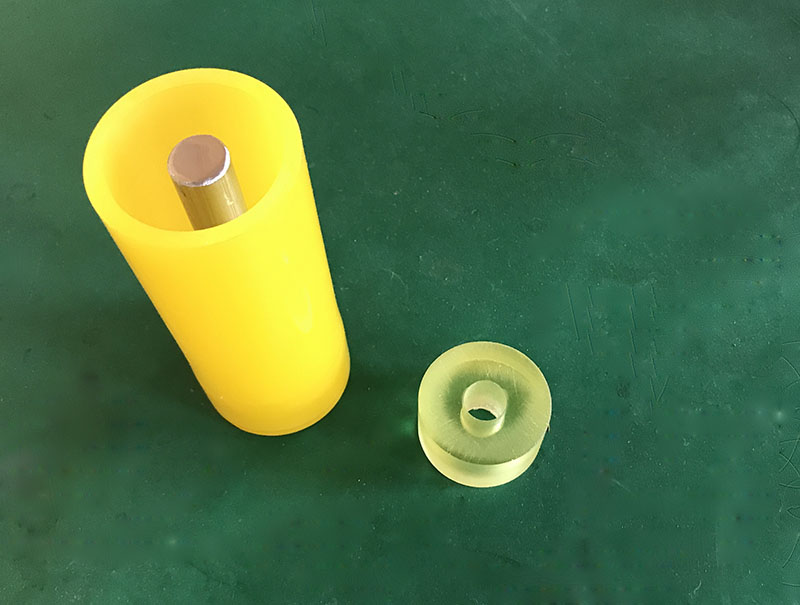

Categories: Polyurethane CIP bag mold

Application: Design and Product Isostatic Pressing Mold

InquiryMain description:

Design and Product Isostatic Pressing Mold

Design and Product Isostatic Pressing Mold

Design and Product Isostatic Pressing Mold

Isostatic pressing process products have outstanding advantages such as uniform structure, high density, small sintering shrinkage, low mold cost, high production efficiency, complex shapes, slender products, large-sized products and precision-sized products. The more advanced molding process has begun to replace the traditional molding method with its unique advantages, such as spark plugs, ceramic balls, plungers, vacuum tube shells and other products produced by ceramics, showing more and more broad application prospects.

In the sealing structure of the isostatic pressing mold, an end cap fitted with the sheath is provided, and the fitting can be done by contacting the outer wall of the end cap with the inner wall of the sheath, or through the end cap The inner wall of the inner wall is in contact with the outer wall of the sheath for fitting, and an elastic sealing ring is provided on the contact surface where the two are fitted. The elastic sealing ring is in a compressed state, so that the end cap can and the sheath are bonded to each other, so as to realize the sealing between the inner and outer cavities of the isostatic pressing mould. Moreover, as a technician in the mechanical field, you can control the parameters of the cross-sectional diameter of the elastic sealing ring and the inner diameter of the elastic sealing ring, and at the same time cooperate with the height of the installation space of the selected elastic sealing ring, and select the size of the elastic sealing ring according to the actual situation. k-factor.

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

Product overview: Isostatic pressing rubber mold is used for the molding of ceramic materials, tungsten and molybdenum materials, graphite materials, refractory materials, and alloy powders. It can be customized according to drawings, and can be designed according to samples.

Product features: The deformation of the elastic mold under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the blank is uniformly stressed, and the density distribution is uniform, and the pre-pressed blank is encapsulated. In the elastic rubber mold, it is put into the high-pressure cylinder after sealing, and the green body is compressed and formed by liquid transfer.

Product advantages: The design of the mold cover is reasonable to ensure no water leakage, the blank is well formed, and the service life is long, including the fixture for processing the blank, which can be customized! There is a free amount of open steel molds.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com