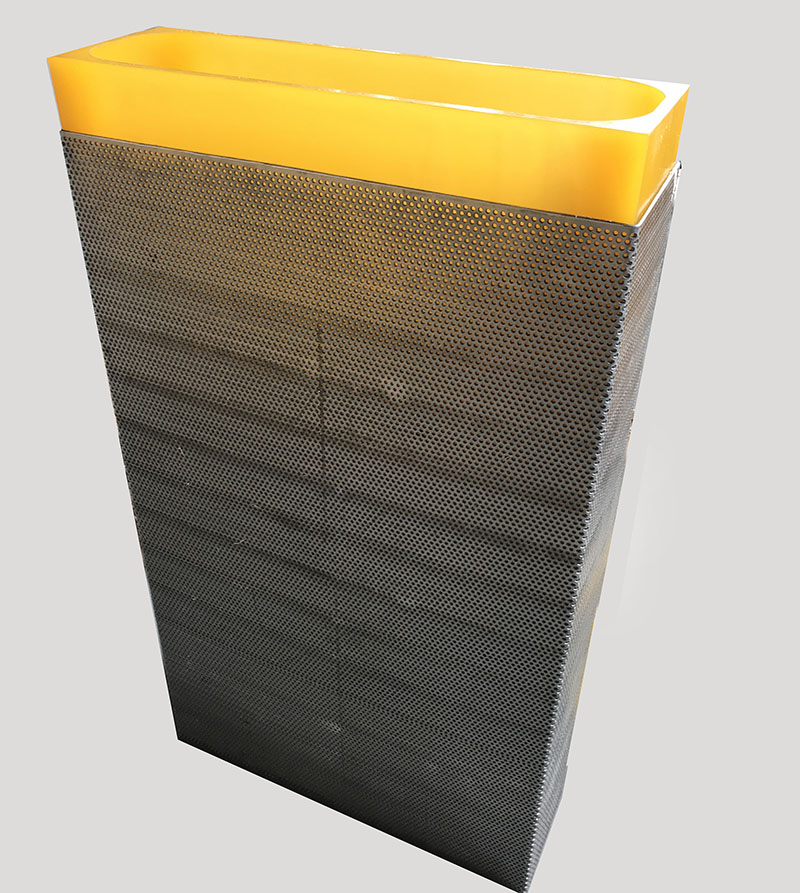

ISOSTATIC PRESSING MOLD

Categories: Powder metallurgy bag mold

Application: ISOSTATIC PRESSING MOLD

InquiryMain description:

ISOSTATIC PRESSING MOLD

ISOSTATIC PRESSING MOLD

ISOSTATIC PRESSING MOLD

Isostatic pressing mold, the traditional isostatic pressing rubber mold rubber sleeve, later the polyurethane material is well known, and now the high-demand isostatic pressing molding is basically made of polyurethane material isostatic pressing rubber sleeve specially used for isostatic pressing. Ordinary polyurethane cannot meet the requirements of isostatic pressing. It is necessary to develop high-molecular polyurethane raw materials according to the characteristics of isostatic pressing, oil resistance, water resistance, tear resistance, wear resistance and other requirements. This material is more expensive, but because of the precise molding and long service life, the overall cost may be lower. Generally, the raw materials used in isostatic pressing are expensive, and the remaining raw materials for precise molding are considerable.

Cold isostatic pressing technology is widely used in the ceramic industry, powder metallurgy, carbon graphite products, and food processing industries. Hot isostatic pressing technology can be applied to improve the structure of metal materials, produce near-net size metal parts, hot-press sintering of special ceramics, densification of ceramics and hard alloys, eliminate or repair product defects, etc.

The main technological process of wet bag cold isostatic pressing is:

Mold assembly, powder filling, bag sealing, bag surface cleaning, mold loading into high-pressure cylinder, pressing, bag taking out, mold demoulding, blank inspection, etc.

Mold assembly

Before the mold is assembled, the size, shape and surface condition of the mold should be checked. If the metal touches are scratched, rusted, deformed, bent, etc., it will make the green compact unable to be demolded or cause defects such as marks on the surface of the blank. Surface treatments should be repaired or replaced at any time. The plastic sheath has been used for a long time and is easily deformed. It is difficult to maintain a certain shape and should be replaced at any time. The surface of the mold should be kept clean and dry to ensure that the powder is not contaminated. The assembly of the mold depends on manual operation. In order to ensure the shape and size of the mold cavity, it must be carefully operated and inspected.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com