Cold Isostatic Pressing Technology

Categories: DIP mold-dry bag isostatic press

Application: Cold Isostatic Pressing Technology

InquiryMain description:

Cold Isostatic Pressing Technology

Cold Isostatic Pressing Technology

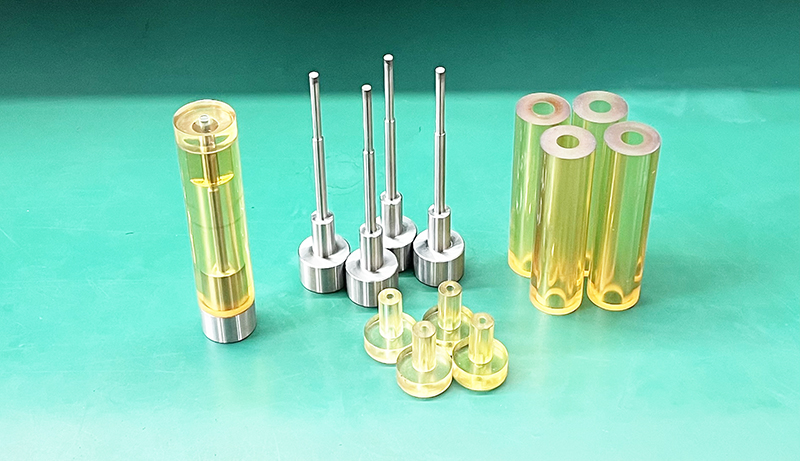

Cold Isostatic Pressing Technology (CIP Bags)

Isostatic pressing is a manufacturing process that uses fluid pressure to compress and shape materials into various forms. It involves applying uniform pressure to a material from all directions, resulting in a uniform density throughout the material. The process is commonly used to produce precision parts with intricate shapes, such as ceramics and metal components. Isostatic pressing can be performed at high or low temperatures, known as cold and hot isostatic pressing, respectively. This process is highly beneficial for producing high-quality, high-density materials with minimal defects.

Cold isostatic pressing (CIP) is a method of compacting materials into parts or products by applying cold, hydrostatic pressure. The process relies on a liquid medium such as water or oil that is forced against the material in order to form it. Cold isostatic pressing that can be used to reduce material porosity and create complex geometries for automotive, aerospace, medical device and other industrial applications. By controlling the levels of cold pressure applied to the material, CIP allows for uniform compaction to prevent cracks and irregularities from forming. This ensures high-quality end products of optimal strength and endurance.

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

Product overview: Isostatic pressing rubber mold is used for the molding of ceramic materials, tungsten and molybdenum materials, graphite materials, refractory materials, and alloy powders. It can be customized according to drawings, and can be designed according to samples.

Product features: The deformation of the elastic mold under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the blank is uniformly stressed, and the density distribution is uniform, and the pre-pressed blank is encapsulated. In the elastic rubber mold, it is put into the high-pressure cylinder after sealing, and the green body is compressed and formed by liquid transfer.

Product advantages: The design of the mold cover is reasonable to ensure no water leakage, the blank is well formed, and the service life is long, including the fixture for processing the blank, which can be customized! There is a free amount of open steel molds.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com