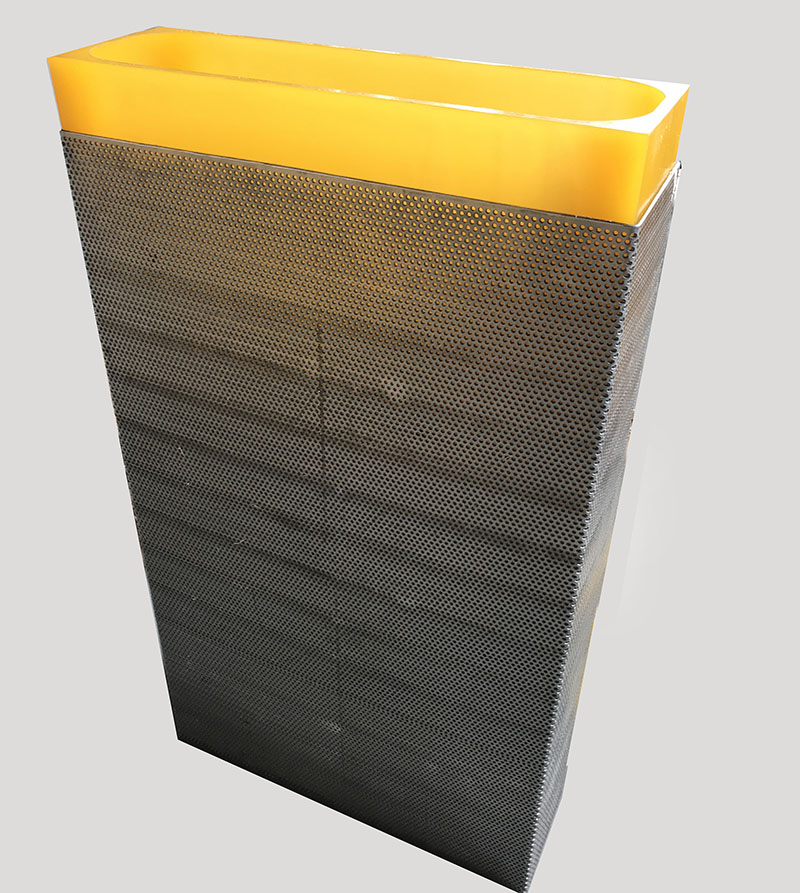

Polyurethane Cold Isostatic Pressing Molds for Powder Metallurgy

In order to improve the mechanical properties and processability of additively manufactured materials, many manufacturers choose isostatic pressing. This process forms components by uniformly applying pressure (using gas or liquid) to a sealed container containing compacted metal powder. Isostatic pressing can be performed at elevated and ambient temperatures, referred to as hot isostatic pressing (HIP) or cold isostatic pressing (CIP), respectively. Hot isostatic pressing can be used to directly manufacture metal components or to densify products produced by other powder metallurgy processes.

Compared with commonly used pressing and sintering methods, isostatic pressing has the advantages of uniform pressure in all directions and a more uniform density of the final component. However, as with other powder metallurgy processes, manufacturers must carefully characterize the properties of the metal powder to ensure successful isostatic pressing. As with other powder metallurgy processes, the properties of the metal powder used in the isostatic pressing process also affect the properties of the final sintered component. Therefore, these properties should be carefully characterized to ensure the desired performance of the final component.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

Polyurethane isostatic molds have higher strength, better elasticity and tear resistance.

Polyurethane isostatic rubber sleeves are non-stick and easy to release from the mold.

Polyurethane isostatic rubber sleeves have stronger anti-aging ability and can be placed for a long time.

The polyurethane isostatic pressing mold has a wide range of hardness adjustment, which can meet the isostatic pressing molding of different materials and different processes.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold