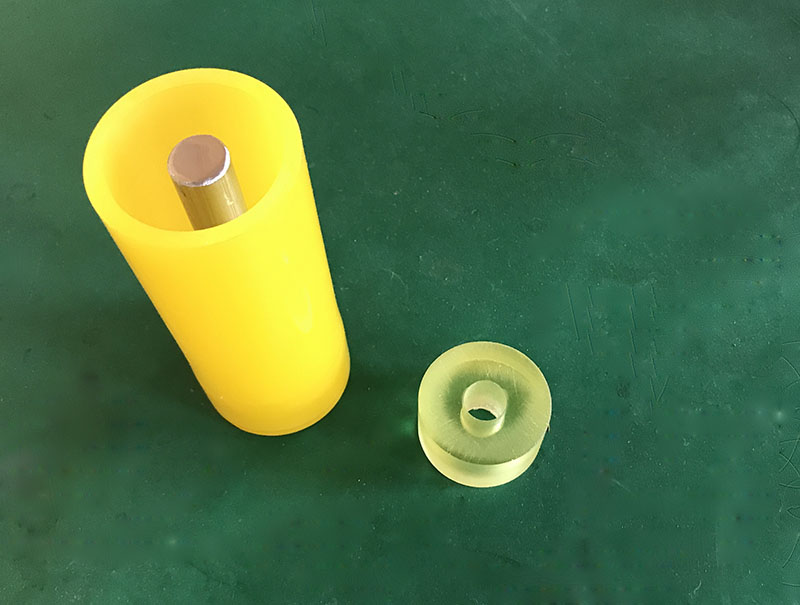

Isostatic Pressing Mold

Categories: Polyurethane CIP bag mold

Application: Isostatic Pressing Mold

InquiryMain description:

Isostatic Pressing Mold

Isostatic Pressing Mold

Isostatic Pressing Mold

Isostatic Press Technology

The compression molding method, also known as the stamping process, is to add a small amount of binder to the powder (the water content must be controlled at 4%-7%, or even 1%-4%) for granulation, and then put the granulated powder in a mold (dry pressing is generally a steel mold, cold isostatic pressing is a rubber film), and pressurize on a pressure machine to form a certain shape. The characteristics of the compression molding method are that the content of the binder is low, it can be directly roasted without drying, and the shrinkage rate of the green body is small. The most widely used compression molding methods are dry pressing and isostatic pressing.

Process principle:

The essence of dry pressing is that under the action of external force, the particles are close to each other in the mold, and the particles are firmly connected by internal friction to maintain a certain shape. This internal friction acts on the thin layer of binder surrounding the particles that are close to each other. As the pressure increases, the blanks will change their shape, slide against each other, the gap will decrease, and the contact will gradually increase, and they will stick tightly to each other. As the particles get closer, the force between the colloid molecules and the particles is strengthened, so the green body has a certain mechanical strength.

Isostatic Pressing Molds for ceramic, metal powder, PTFE and so on

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com