The Applications of Cold Isostatic Pressing

Categories: DIP mold-dry bag isostatic press

Application: The Applications of Cold Isostatic Pressing

InquiryMain description:

The Applications of Cold Isostatic Pressing

The Applications of Cold Isostatic Pressing

The Applications of Cold Isostatic Pressing

The cold isostatic pressing technology adopts Pascal’s principle to put the product into a closed ultra-high pressure container, and the liquid (oil/water) mesons evenly act on the surface of the product, and the pressure is equal in all directions, so as to realize the dense and isotropic requirements of the powder product, and provide prefabricated blanks for the further preparation and processing of the product, such as sintering, forging and extrusion.

The cold isostatic pressing process can produce powder molding products with high density, uniform density, isotropy, large slenderness to diameter ratio, complex shape and close to the end shape. It is widely used in the molding of various types of hard alloys, tungsten-molybdenum refractory materials, titanium-nickel powders, refractory materials, graphite carbon, high-voltage electric ceramics, magnetic materials, industrial ceramics, artificial diamonds and other products. In recent years, great progress has been made in the test and engineering application of cold isostatic pressing technology in food sterilization and preservation, virus inactivation, bioactive substances, and extraction of traditional Chinese medicine.

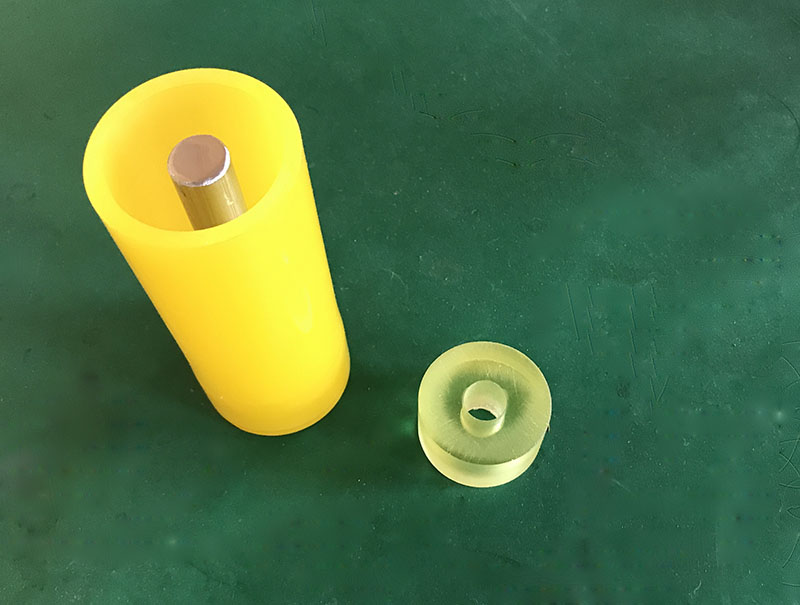

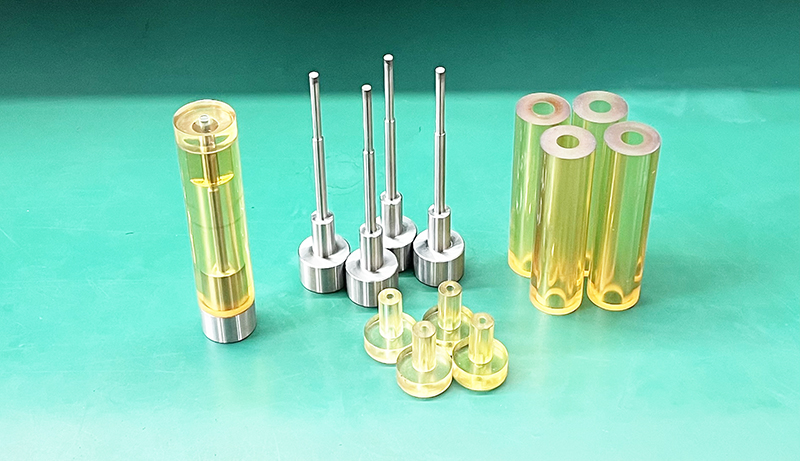

A Samples of CIP Molds

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com