Isostatic Pressing Bags for Powder Forming

Categories: DIP mold-dry bag isostatic press

Application: Isostatic Pressing Bags for Powder Forming

InquiryMain description:

Isostatic Pressing Bags for Powder Forming

Isostatic Pressing Bags for Powder Forming

Isostatic Pressing Bags for Powder Forming

Isostatic pressing is a new forming method developed with the rise of modern powder metallurgy technology. Generally, isostatic pressing is divided into cold isostatic pressing and hot isostatic pressing according to its characteristics. The former is commonly used as water or oil as the pressure medium, so it is called hydrostatic pressure, hydrostatic pressure or water-oil hydrostatic pressure.

Isostatic pressing products have the advantages of uniform structure, high density, small sintering shrinkage, low mold cost, high production efficiency, complex shape, slender products, large-sized products and precision-sized products.

Cold isostatic pressing is to pour (put) powder into a flexible sheath, or put a pre-pressed billet into a working cylinder to compress it into a part that is close to net shape. The powder can be metal, ceramic or graphite powder, put it into a sealed flexible mold with the same shape as the product, use oil or water as the medium, and apply ultra-high pressure up to 600Mpa in the pressure cylinder, so that the same ultra-high pressure acts on all surfaces of the object, so that parts with uniform structure and high density can be obtained, so that they shrink evenly during sintering, improve mechanical properties, and facilitate machining. With the continuous development of science and technology, it has been widely used in many industrial fields such as magnetic materials, ceramics, hard alloys, graphite, and rare metal powder molding to improve the strength and wear resistance of parts.

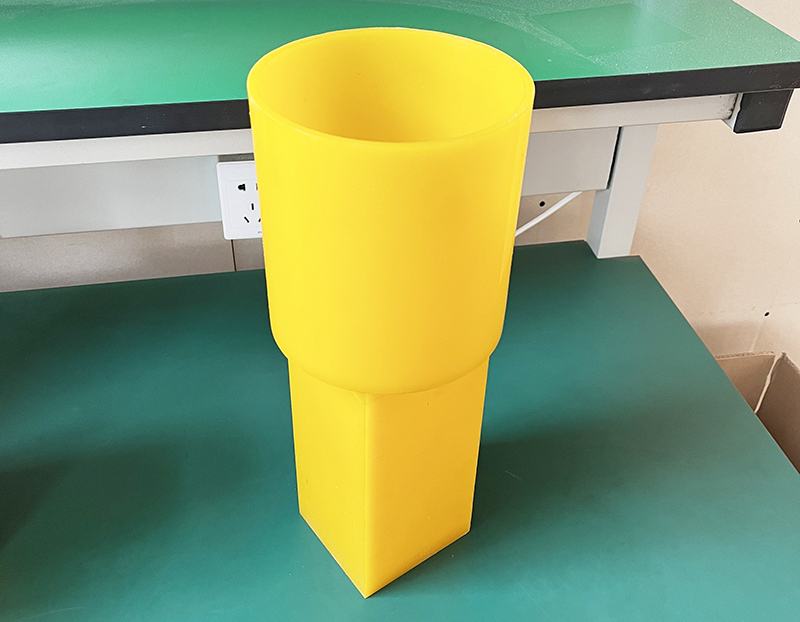

A Samples of Isostatic Press Molds

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com