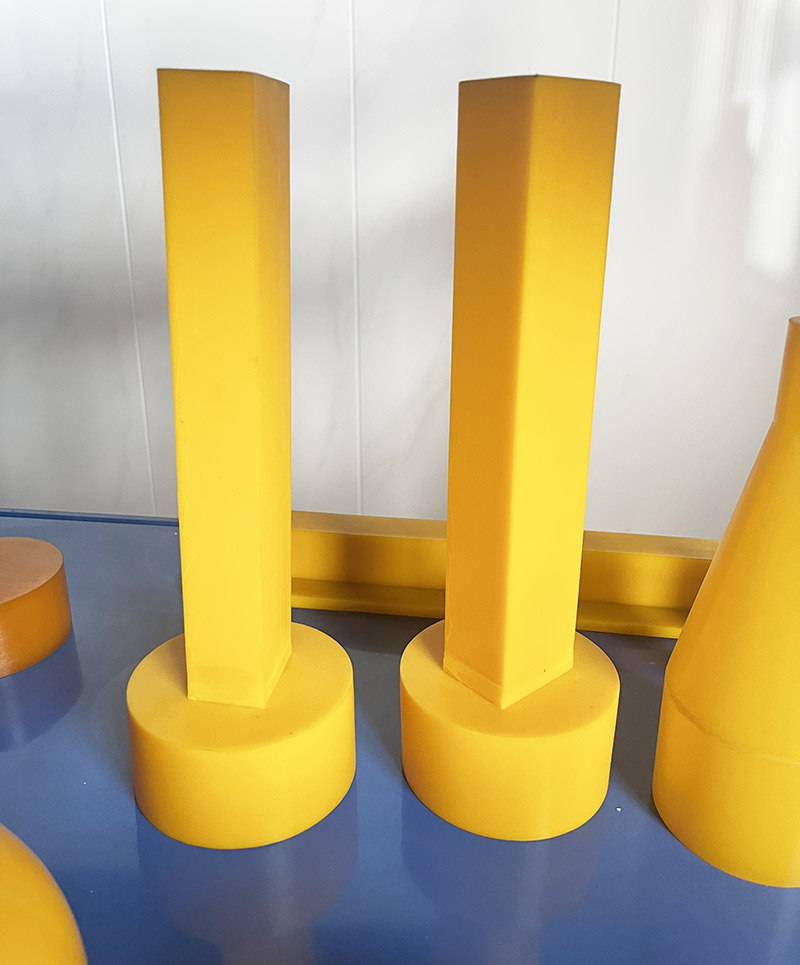

Polyurethane ISO mold for Magnet Production

Categories: DIP powder forming mold

Application: Polyurethane ISO mold for Magnet Production

InquiryMain description:

Polyurethane ISO mold for Magnet Production

Polyurethane ISO mold for Magnet Production

Polyurethane ISO mold for Magnet Production

The process of the magnet production process: isostatic pressure

The density of the green billet pressed by the magnetic field oriented molding process is about 3.2-3.8g/cm, and the ideal density of the Ndfeb magnet after sintering should be about 7.5g/cm, so when pressing the relatively large cylinder and box, it is easy to crack due to the large shrinkage, deformation and dimensional out-of-tolerance, so it is also necessary to put the isostatic press through isostatic pressure to improve the density of the green billet. After isostatic pressure, the density of green billet is 4.5g/cm, magnet manufacturers currently in addition to low performance small pillars (with a diameter of 10mm or less) unequal static pressure directly into the sintering furnace after the other specifications have to go through the isostatic pressure link, and isostatic pressure green billet in order to prevent oil immersion and surface oxidation, must be vacuum packaging, stripping oil before entering the furnace.

The working principle of the isostatic press is PASCAL's principle, which puts the green billet into a closed ultra-high pressure container, and continuously presses hydraulic oil into the sealed container through the booster pump, so that the hydraulic pressure in the sealed container continues to increase, and the general pressure is 100~ 630MPa. The high pressure liquid uniformly acts on the surface of the rubber sleeve, and compresses the granulated material in the rubber sleeve to form it. Because the isostatic pressure is characterized by equal pressure in all directions, the blank density after forming is uniform, the organization structure is uniform and isotropic.

Polyurethane Mold required for isostatic pressing process

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com