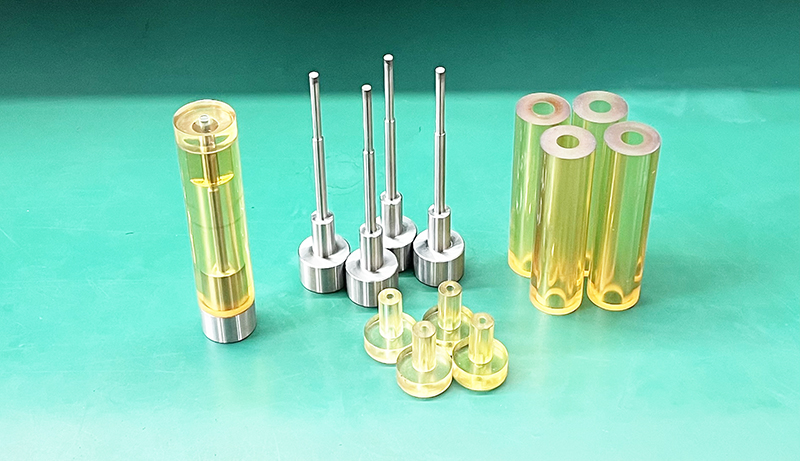

ISO Pressing Molds

Categories: Polyurethane CIP bag mold

Application: ISO Pressing Molds

InquiryMain description:

ISO Pressing Molds

ISO Pressing Molds

ISO Pressing Molds

Isostatic pressure method is also known as balanced forming method or bag molding method. Cold processing method using fluid pressure instead of commonly used press to form polytetrafluoroethylene products. High-pressure fluid is used to force the impermeable elastic film to expand or compress, so that the polytetrafluoroethylene resin remaining between the elastic film and the mold wall is uniformly and regularized to become a pre-formed product of various required shapes. The elastic film can be made of natural rubber bag or latex bag. A high-pressure fluid can be a gas (called the barometric method) or a liquid (called the hydraulic method).

The hydraulic method using water as a high pressure fluid is widely used. According to the relative position of the elastic film and the metal mold, the hydraulic method can be divided into internal pressure method (dry bag method,), the elastic film is in the mold, which is suitable for processing the products with smooth and clean peripheral requirements; External pressure method (wet bag method), the elastic film is placed in the pressure chamber, the mandrel is placed in the bag, the polytetrafluoroethylene resin is filled between the mandrel and the elastic film, and the hydraulic pressure is applied between the pressure chamber and the elastic film to make it formed, which is suitable for processing the internal requirements of smooth products. The advantages are simple structure of molding equipment and mold, fast production, easy operation, uniform product pressure.

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

Product overview: Isostatic pressing rubber mold is used for the molding of ceramic materials, tungsten and molybdenum materials, graphite materials, refractory materials, and alloy powders. It can be customized according to drawings, and can be designed according to samples.

Product features: The deformation of the elastic mold under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the blank is uniformly stressed, and the density distribution is uniform, and the pre-pressed blank is encapsulated. In the elastic rubber mold, it is put into the high-pressure cylinder after sealing, and the green body is compressed and formed by liquid transfer.

Product advantages: The design of the mold cover is reasonable to ensure no water leakage, the blank is well formed, and the service life is long, including the fixture for processing the blank, which can be customized! There is a free amount of open steel molds.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com