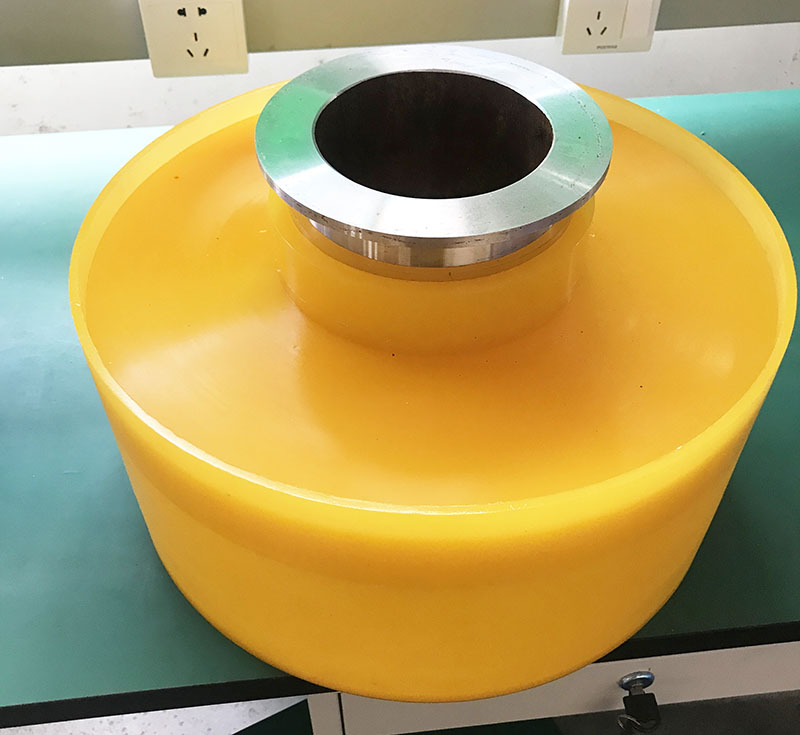

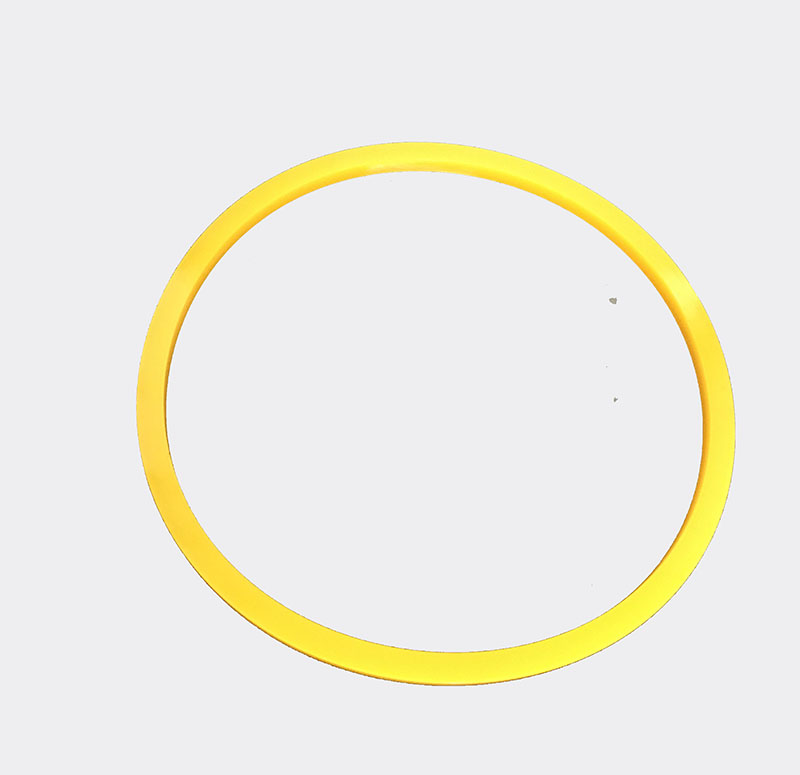

CIP tooling cold isostatic pressing bags isopressing mold ISO tooling for powder and powder molding

Categories: Powder metallurgy bag mold

Application: CIP tooling cold isostatic pressing bags isopressing mold ISO tooling for powder and powder molding

InquiryMain description:

The cold isostatic pressing method is to put the pre-formed green body into the polyurethane isostatic pressing jacket of Hyderland and immerse it in a high pressure liquid to make it bear isotropic pressure, so as to strengthen the density of the green body. Cold isostatic pressing is only to obtain a green body with the highest possible density, which makes the sintering and densification of the green body easier.