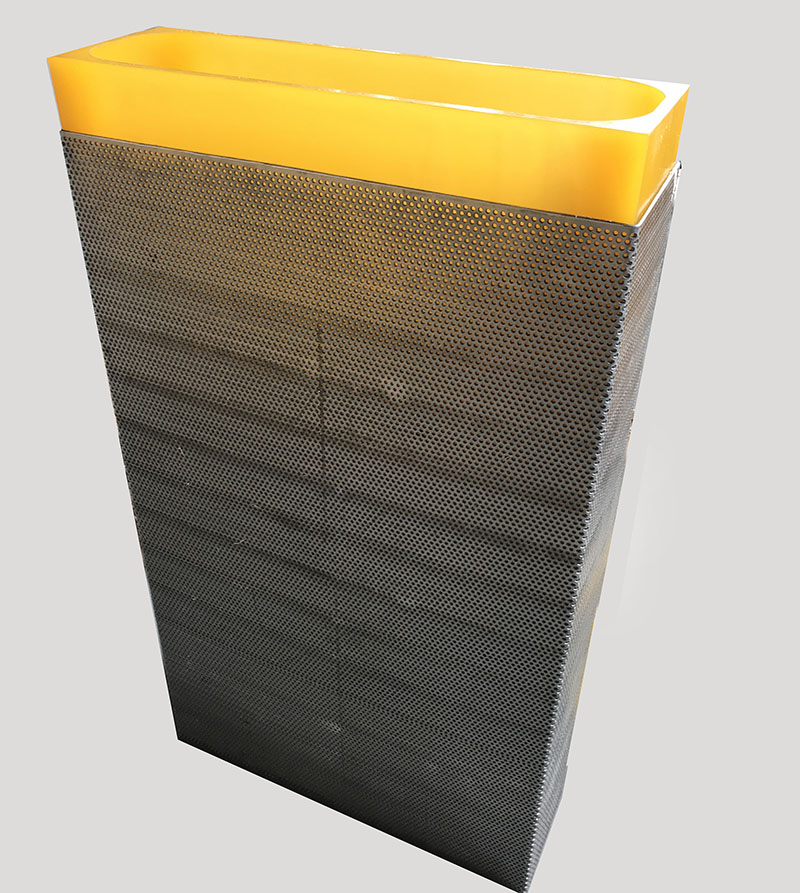

Polyurethane Cold Isostatic Pressing Molds

Categories: Cold isostatic pressing mold

Application: Polyurethane Cold Isostatic Pressing Molds

InquiryMain description:

Polyurethane Cold Isostatic Pressing Molds

Polyurethane Cold Isostatic Pressing Molds

Polyurethane Cold Isostatic Pressing Molds

Cold isostatic pressing is referred to as isostatic pressing. The static pressure generated by the fluid or gas is directly acted on the powder or billet in the elastic mold sleeve through the high pressure pump, so that it is pressed by the uniform pressure in all directions. The isostatic pressing of zirconia ceramics can be divided into cold isostatic pressing and hot isostatic pressing according to its characteristics. Isostatic pressing technology can produce new alloy products which are difficult to produce by casting technology, and the products have uniform density and no residual stress. The advantages of no mold wall friction, no additives and binders are usually used to manufacture large and shaped parts with high density.

The cold isostatic forming method has the following characteristics:

① it can form large and slender products with complex shapes that cannot be produced by general methods, and the forming quality is high;

②The forming pressure can be easily improved without increasing the difficulty of operation, and the pressure effect is better than other dry pressing methods;

③ Because the blank body is under uniform pressure in all directions, its density is high and uniform, and the firing is reduced, so it is not easy to deform;

④ The mold is easy to make, long life and low cost;

⑤ Little or no binder can be used.

Cold isostatic pressure is divided into wet and dry isostatic pressure. Wet isostatic pressing is to wrap the pre-pressed blank in an elastic rubber mold or plastic mold, and then put it in a high-pressure container with high-pressure liquid, and the forming pressure of the blank body is usually more than 100MPa. It is characterized by the mold in high pressure liquid, pressure in all directions. This method is mainly suitable for forming multi-variety, complex shape, small yield and large products.

Compared with wet isostatic pressure, the mold is not in liquid, but semi-fixed, and the addition of billets and the extraction of billets are operated in a dry state, so it is called dry isostatic pressure. Dry isostatic pressing is more suitable for the production of simple shape of long, thin wall, tubular products, if slightly improved, can be used in continuous automated production.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mold, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mold, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com