Wet-bag Isostatic Pressing Bags and Dry-bag Isostatic Pressing Bags

Wet bag structure, wet bag is made of rubber, polyethylene and other soft bags, made of powder soft bag. When in use, the soft bag is placed directly into the oil and in direct contact with the liquid. After the pressing is completed, the powder compact and the rubber bag are removed together, and the oil on the surface of the rubber bag is wiped dry before the compact is removed from the rubber bag. This method is called wet bag method. Because it is often in contact with greasy rubber bags, the hands are greasy and sticky when the compact demoulding, and it is not easy to operate.

Dry bag structure. The dry bag structure is fixed and sealed on the mouth of the high-pressure cylinder block by using double rubber bags and pressurized rubber bags, and the high-pressure oil is limited to a small space between the steel mold and the pressurized rubber bag. The rubber bag containing powder (or not) is placed in the pressure forming rubber bag, and the powder is extruded by the pressure rubber bag. This structure is very convenient for loading powder and taking pressure parts. In particular, the production is not in contact with the oil, the workpiece is clean, and the working conditions are good, so the production efficiency is very high (up to 10 to 15 pieces /min).

Dry bag method has been widely used in the production of high-strength ceramic cemented carbide bars and magnetic materials, especially in recent years, Monostatic series dry bag isostatic press produced by British Himark Company has a high production efficiency and the surface of high pressure blank is smooth. High dimensional accuracy can produce ceramic compact with complex shapes.

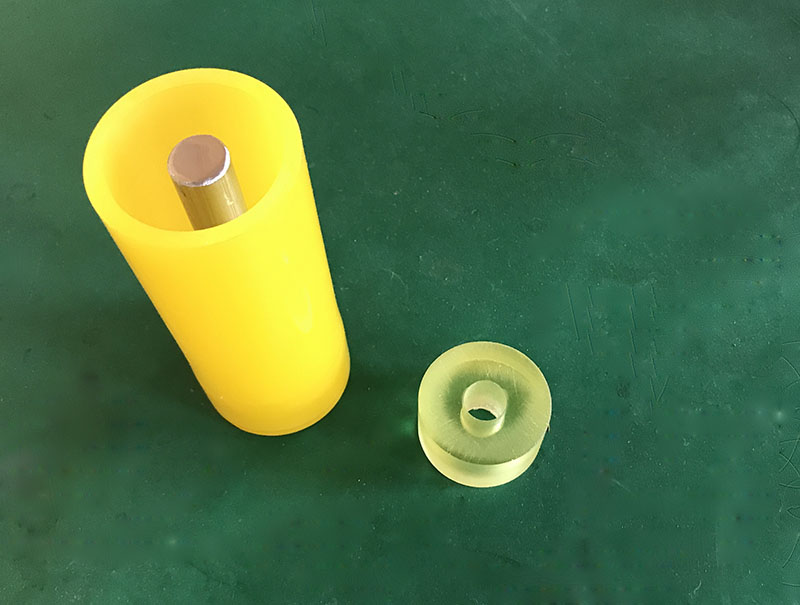

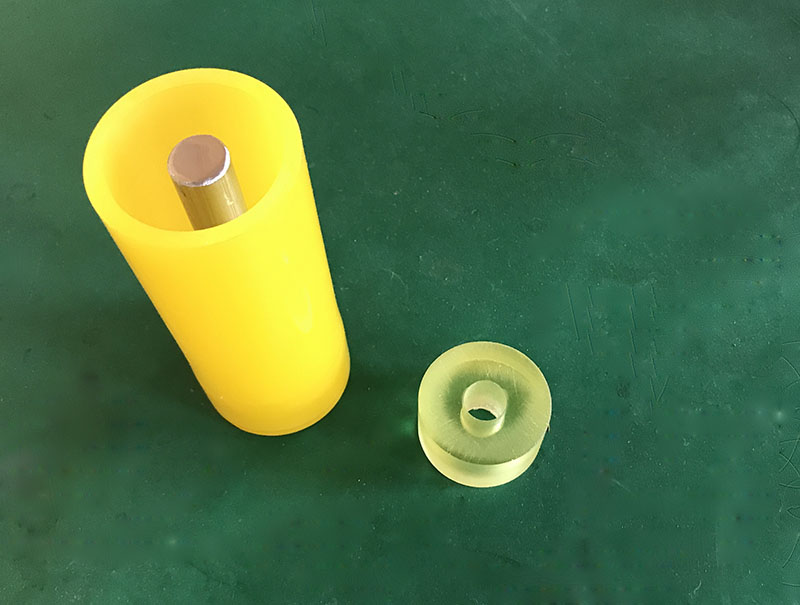

· Wet-bag isostatic pressing bags

· Dry-bag Isostatic Pressing bags

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold