ISO Bags for Composite Materials Molding

Categories: Isopressing mold

Application: ISO Bags for Composite Materials Molding

InquiryMain description:

ISO Bags for Composite Materials Molding

ISO Bags for Composite Materials Molding

ISO Bags for Composite Materials Molding

Composite materials, also known as high-performance composite materials, are new materials that are optimized by using advanced material preparation technology to combine material components with different properties.

Definition of composite materials

Composite materials must be man-made, designed and manufactured according to the needs of people. And the composite material must be composed of two or more materials with different chemical and physical properties, there is an obvious interface between the components, and it has structural designability and can be designed as a composite structure. It not only maintains the advantages of the properties of each component material, but also can obtain the comprehensive properties that can not be achieved by a single component material.

Classification and application of composite materials

Composite materials have played a great role in many fields such as aerospace, automotive industry, chemical industry, textile, medicine and so on, replacing many traditional materials. It can be divided into metal and metal composite materials, non-metal and non-metal composite materials.

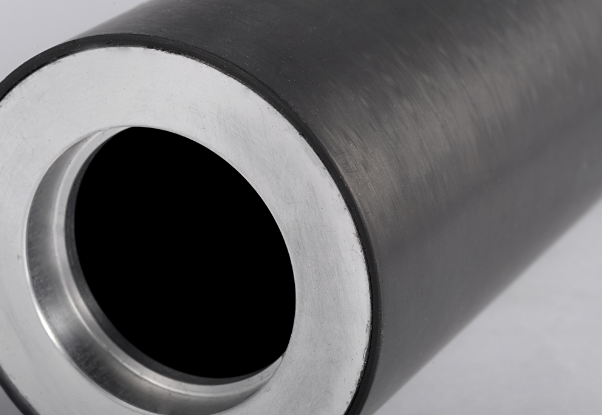

Bag pressing is a method of making the reinforced plastic between the rigid mold and the elastic bag under uniform pressure by means of the fluid pressure received by the elastic bag (or other elastic diaphragm). The process of processing polytetrafluoroethylene and other materials is isobaric forming, and bag pressing is one of the important methods for preparing thermosetting materials and large composite devices.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com