Cold Isostatic Pressing Bags for Sintered Metal Powder Filter

Cold isostatic pressing: Usually the powder is sealed in a soft envelope, and then placed in the liquid medium in a high pressure container, by applying pressure to the liquid to make the powder body under uniform pressure in all directions, the metal powder pressing molding process, so as to obtain the required compact. The liquid medium can be oil, water or glycerin. The jacket material is elastoplastic material such as rubber, and the metal powder can be installed directly or after molding. Because the powder is under uniform pressure in all directions in the envelope, a compact with a more uniform density can be obtained, which is not easy to deform and crack during sintering. Cold isostatic pressing has been widely used in the forming of cemented carbide, refractory metal and other powder materials.

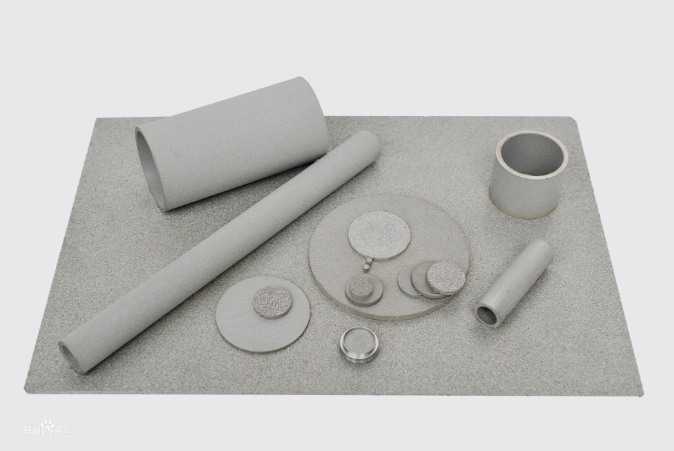

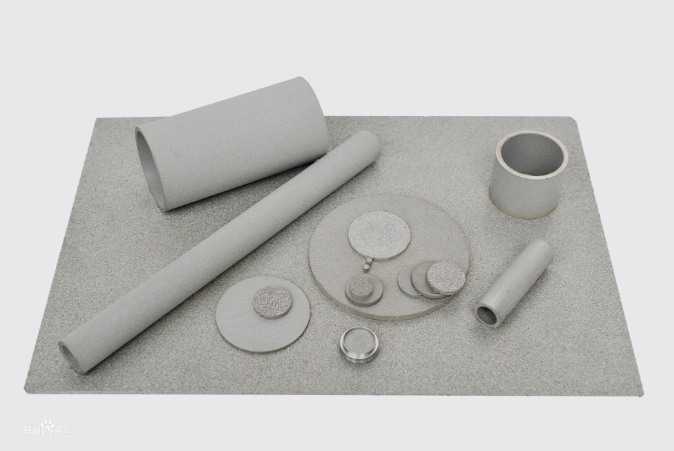

Sintered metal powder filter element uses metal powder as raw material without adding adhesive. After forming by cold isostatic pressing, it is made by high temperature vacuum sintering. The pore size and distribution of the component can be adjusted by selecting the particle size and process parameters of the metal powder. By using the pore structure, material composition, compressive strength and other characteristics of different filtration materials, the filtration products suitable for users are developed.

Sintered metal powder filter element can achieve micron-level precision filtration, can separate solid particle impurities in liquid and gas, when the fluid passes through a certain precision filter element, the impurities are blocked on the surface of the filter to form a filter cake, pure fluid flows through the filter element, so that the contaminated or containing impurities of the fluid clean to the normal production required state. To ensure that downstream devices obtain pure products or protect the normal operation of equipment.

Different from the non-metallic sintered filter element, when the filter cake on the surface of the sintered metal powder filter element reaches a certain thickness, because of its high strength performance characteristics, the filter element can be cleaned by backwashing or backblowing through a certain reverse pressure, so that the filter element can be used again.

A Sample of CIP Bags

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold