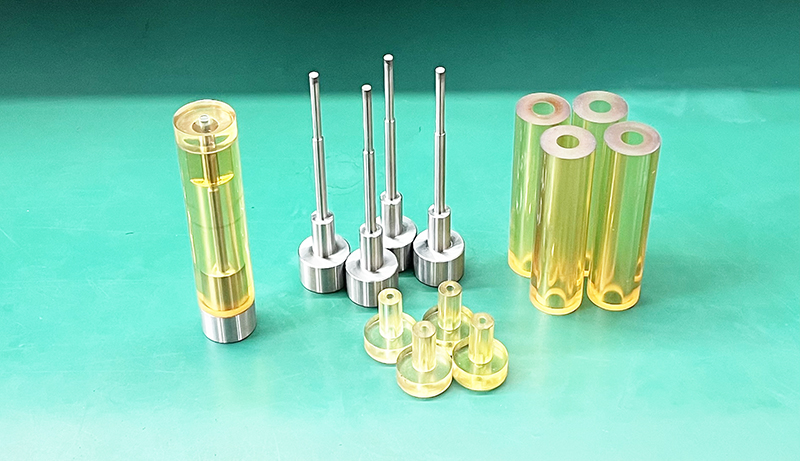

The Polyurethane Mold for Powder Sintered Filter

Categories: Isopressing mold

Application: The Polyurethane Mold for Powder Sintered Filter

InquiryMain description:

The Polyurethane Mold for Powder Sintered Filter

The Polyurethane Mold for Powder Sintered Filter

The Polyurethane CIP Mold for Powder Sintered Filter

Common powder sintered filter types are stainless steel powder sintered filter, metal titanium powder sintered filter, copper powder sintered filter. The filtration principle is to adjust the pore size and distribution by selecting the powder particle size and process parameters, while using the pore structure, material composition, compressive strength and other characteristics of different filtration materials to achieve effective filtration. Its filtration accuracy reaches the nanometer level and can be used to separate impurities such as suspended matter and solid particles in liquids and gases.

Powder sintered filter element is completely composed of metal spherical powder, the aperture is smooth, the size is uniform, the initial resistance is small, can be repeatedly cleaned and reused; No adhesive is added in the production process of the filter element, no shedding matter and no dissolution matter, and it can be used instead of the titanium rod filter element in the decarbonization process of the pharmaceutical industry.

At the same time, powder sintering filter is first through cold isostatic pressing technology, at room temperature with rubber or plastic materials as a sheath mold, with liquid as the pressure medium, so that the powder molding, and then through high temperature vacuum sintering made. Its shape is stable, has high strength and good permeability, high temperature and pressure resistance, strong acid and alkali resistance, oxidation resistance, its impact resistance and alternating load capacity is also much higher than other metal filtration equipment.

Moreover, because its metal material has generally high strength properties, when the filter cake on the surface of the powder sintered filter reaches a certain thickness, the filter can be cleaned by backwashing or backblowing through a certain reverse pressure, so that the filter can be used again. Therefore, the service life of powder sintered filter element is also longer, which can effectively reduce the operating cost invested in use.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com