Customized CIP Molds

Categories: Cold isostatic pressing mold

Application: CIP Molds

InquiryMain description:

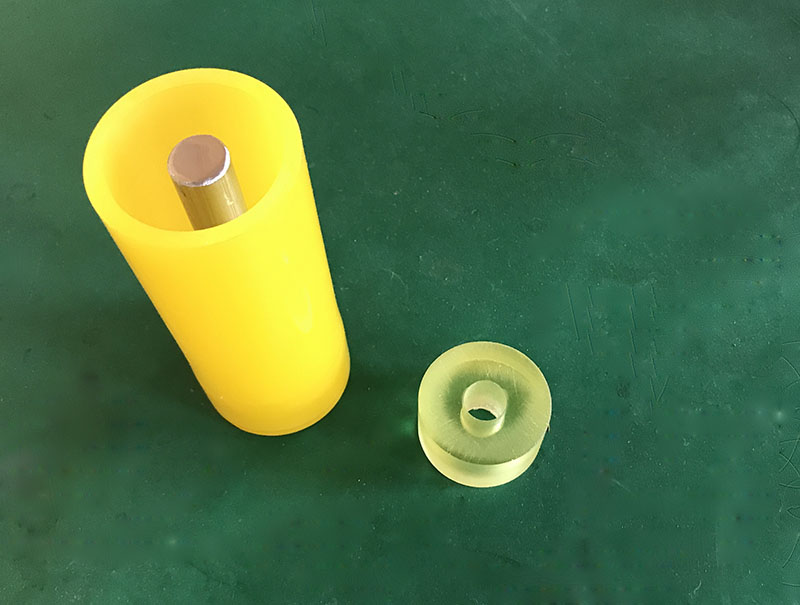

Customized CIP Molds

Customized CIP Molds

CIP Molds

In the cold isostatic pressing forming technology, according to the different forming methods, the envelope and the mold are divided into wet bag method, dry bag method and balanced pressing method. No matter what kind of mold, it is composed of four basic components: plastic die, rigid die, port sealing device and support device.

Plastic die covers, end plugs and die pads are made of materials such as rubber or plastic. In cold isostatic pressing, plastic die not only plays the role of mold, but also plays the role of transferring pressure to make the powder compact. The core and mold of rigid molds are made of metal materials. The size and shape of the rigid die remain unchanged during the forming process.

In the normal mass production of cold isostatic molding mold design, there are usually the following steps:

(1) A small simulation test is carried out to determine the compression ratio of the powder during molding. The relationship between the pressure and the compact density and strength, the shrinkage rate of the compact after sintering and other basic data.

(2) According to the obtained test data. The machining allowance and dimensional tolerance after molding are also considered. Carry on the mold shape position size design, and then check through the measured results. After repeated tests until the shape, size and performance of the molded billet meet the technical requirements.

(3) The selection of cladding materials, determine the wall thickness of the cladding and the metal core material, and determine the assembly method of the mold, the sealing of the charging port and the port, the fixing device, etc. If there is practical experience and data in this work, the design steps can be simplified. In short, in the design of the mold, we should pay attention to the rationality of the design and take into account the economic practicability of the mold.

The main factors affecting the design of the envelope and mold are as follows:

In jacket and mold design, there are a number of factors to consider, of which the powder filling density is the most critical. The uniformity of filling density and the size of filling density in the mold are the main basis of mold design.

The filling density of the material in the mold is affected by the following three aspects.

(1) Influence of powder characteristics on filling density. The influence of powder characteristics on filling density refers to the influence of particle shape, particle size composition and surface state of powder on filling density. The filling density of regular spherical particles is higher than that of irregular dendritic particles. The packing density of powder with particle gradation is higher than that of powder with single particle size.

(2) The effect of the filling method of powder. In practice, natural filling, artificial vibration, artificial compaction, mechanical vibration, centrifugal filling and so on are usually used. Among them, the natural filling density is the lowest. Mechanical compaction packing density is the highest. Although high filling density can be obtained by manual compaction, the orientation is not uniform, and the flatness of the compact surface is poor.

(3) The influence of the mold itself. In the filling process, there is internal friction between powder particles and external friction between powder and film, which limits the fluidity of powder in the mold cavity. For this. The charging port of the mold should be at the highest point of the mold cavity. In order to reduce the friction between the powder and the mold wall during the filling process, the surface of the mold wall should be as smooth and straight as possible. For plastic cladding. A support device shall be provided outside the jacket. It is beneficial to increase the filling density of powder.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com