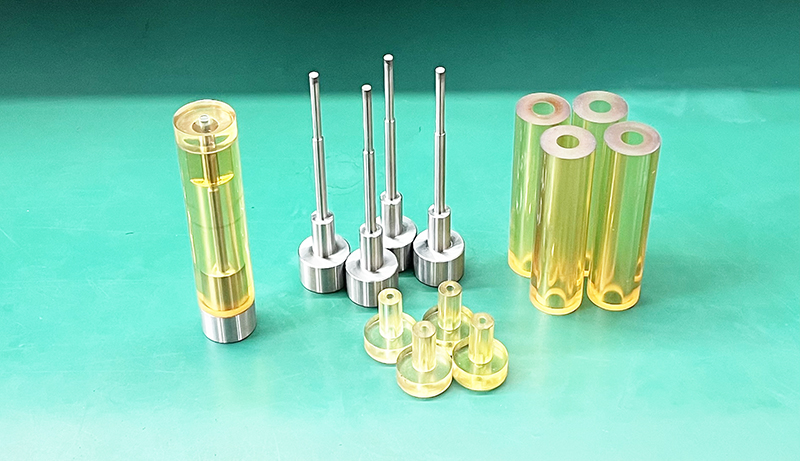

ISO Bags for PTFE

Categories: Powder metallurgy bag mold

Application: ISO Bags for PTFE

InquiryMain description:

ISO Bags for PTFE

ISO Bags for PTFE

ISO Bags for PTFE

Teflon commonly known as teflon, also known as plastic king, the melting point is 327 ° C, its melting viscosity is very large, several orders of magnitude higher than ordinary thermoplastics, in the molten state can still maintain the original shape, similar to the state of jelly can not flow, so PTFE can not use injection molding and other conventional plastic molding process, usually using cold pressing sintering molding process, The polytetrafluoroethylene powder is pressed into the desired shape at room temperature, and then sintered at high temperature, and then machined to achieve the desired size.

Die molding, also known as compression molding, is to fill the PTFE material into the mold, under pressure to gather the powder together to become the required shape, usually used to press tubes, rods, plates, cakes, gaskets, film blanks and pipe lining and other special-shaped parts. Isobaric molding is a special form of molding to make special-shaped parts, usually the outer mold is metal, the inner mold is skin, and the PTFE powder is filled between the inner and outer molds, and the pressure is injected into the mold to compact the powder.

Hydraulic method, also known as the isobaric method or rubber bag method, is a special method for making PTFE products, which is to apply hydraulic pressure to the rubber bag so that the rubber bag will expand the PTFE resin to the mold, so that it is compacted and fired into products. The basic operation process is as follows: put the rubber bag in the outer mold - connect the pump, fill the tap water to make the rubber bag into a cylindrical shape - evenly add the resin between the bag and the outer mold - close the mold - continue to fill the water and gradually increase the water pressure, hold the pressure for 12-13Mpa for 30min, and then release the water - decompress, remove the mold, sintering, and cooling, which is the preproduct with a smooth appearance.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com