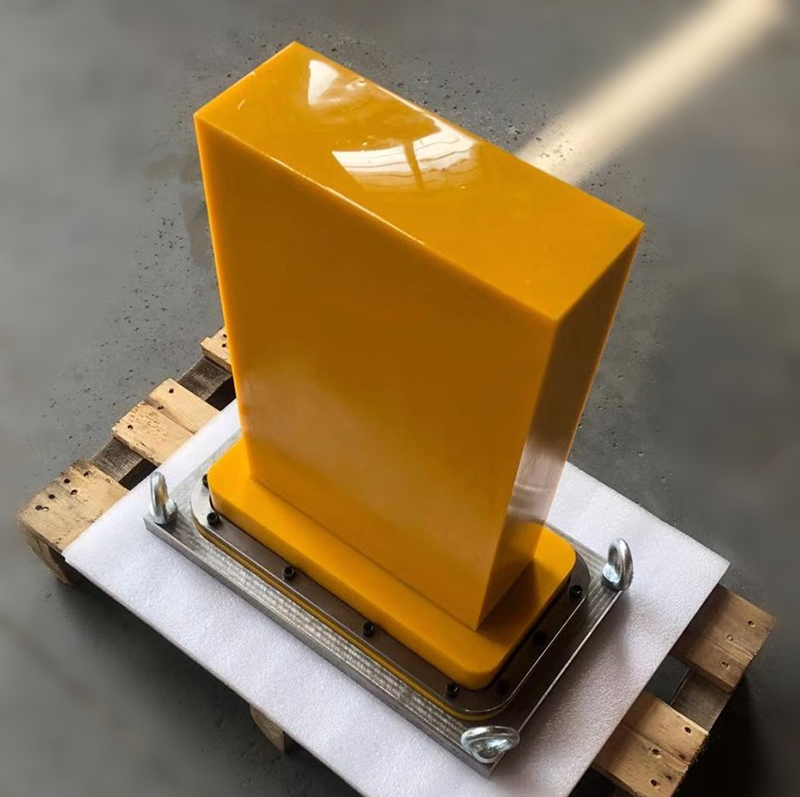

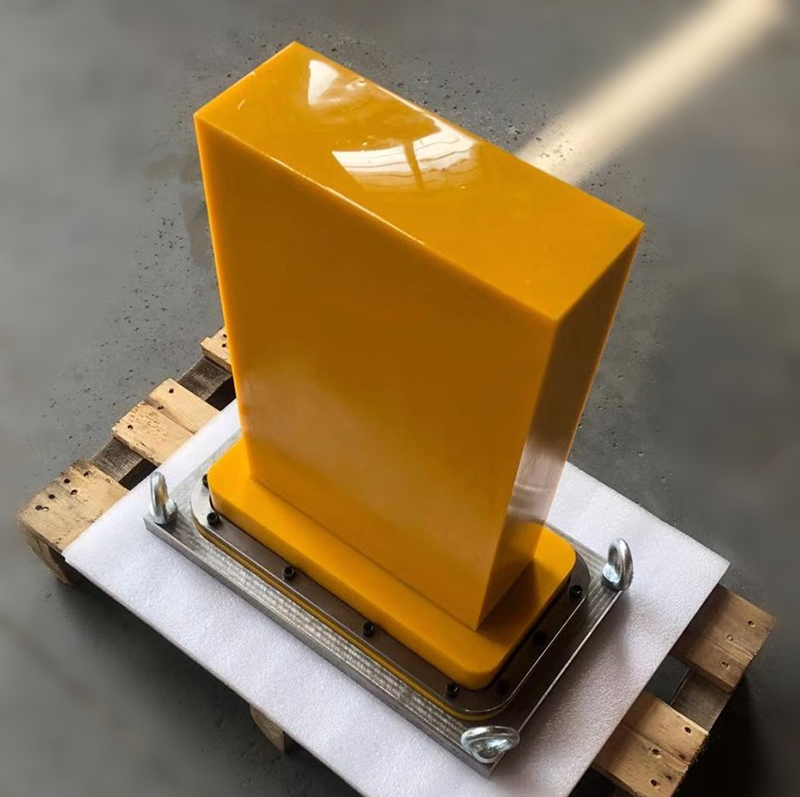

Polyurethane ISO Bags for Ceramic

Categories: Cold isostatic pressing bags

Application: Polyurethane ISO Bags for Ceramic

InquiryMain description:

Polyurethane ISO Bags for Ceramic

Polyurethane ISO Bags for Ceramic

Polyurethane ISO Bags for Ceramic

Isostatic pressing of special ceramics

Special ceramics are new materials with a series of excellent properties such as wear resistance, corrosion resistance, high temperature resistance, oxidation resistance, high hardness, etc., which are widely used in chemical industry, metallurgy, petroleum transportation, mechanical seals, information, energy, aerospace and national defense fields. And the high-tech field has high requirements for the shape and dimensional accuracy of special ceramics. Ceramic material is essentially a brittle material, coupled with its high hardness, high wear resistance characteristics, increase the difficulty of subsequent processing and processing costs. Therefore, improving the performance reliability of materials, realizing the precision molding of complex shaped parts, and reducing the preparation and processing costs of materials have become important issues in the development of special ceramics.

Ceramic molding is the ceramic raw materials in accordance with the actual production requirements into a specified shape, size and a certain strength of the green, the molding process depends on the performance of ceramic raw materials and molding process.

Isostatic press forming:

Isostatic pressing is a method by which the powder is compressed while forming by applying various isostatic pressures. According to the different forming temperature, isostatic pressing is divided into hot isostatic pressing and cold isostatic pressing. Cold isostatic pressing is the isostatic pressing method of forming the workpiece at room temperature. Hot isostatic pressing refers to the isostatic pressing method of sintering the workpiece under high temperature and high pressure.

The sample to be pressed is placed in a high pressure container, and the sample is pressurized uniformly from all directions by using the incompressible nature of the liquid medium and the property of uniform pressure transfer. When the liquid medium is injected into the pressure container through the pressure pump, the pressure is unchanged and uniformly transferred to all directions according to the principle of fluid mechanics. The method of forming dense billet from poor powder by the above method is called isostatic pressing method.

Process features: accurate shape, high efficiency, complex equipment and technical conditions.

Advantages: It can press parts with concave, hollow, slender and other complex shapes; Low friction loss, low forming pressure; The pressure is transmitted from all aspects, the compact density is evenly distributed, the compact strength is high, the mold is convenient, the life is long, and the cost is low.

Disadvantages: the size and shape of the compact is not easy to accurately control, the productivity is low, and the investment is large, the operation is more complex, the molding is operated under high pressure, and the container and other high pressure parts need special protection.

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

Product overview: Isostatic pressing rubber mold is used for the molding of ceramic materials, tungsten and molybdenum materials, graphite materials, refractory materials, and alloy powders. It can be customized according to drawings, and can be designed according to samples.

Product features: The deformation of the elastic mold under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the blank is uniformly stressed, and the density distribution is uniform, and the pre-pressed blank is encapsulated. In the elastic rubber mold, it is put into the high-pressure cylinder after sealing, and the green body is compressed and formed by liquid transfer.

Product advantages: The design of the mold cover is reasonable to ensure no water leakage, the blank is well formed, and the service life is long, including the fixture for processing the blank, which can be customized! There is a free amount of open steel molds.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com