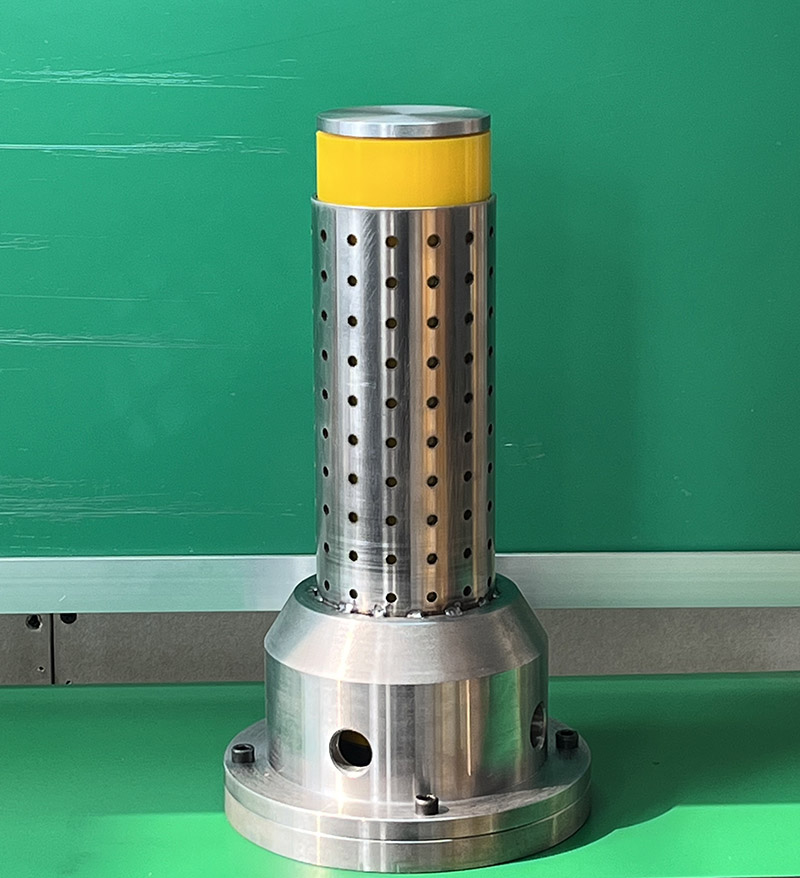

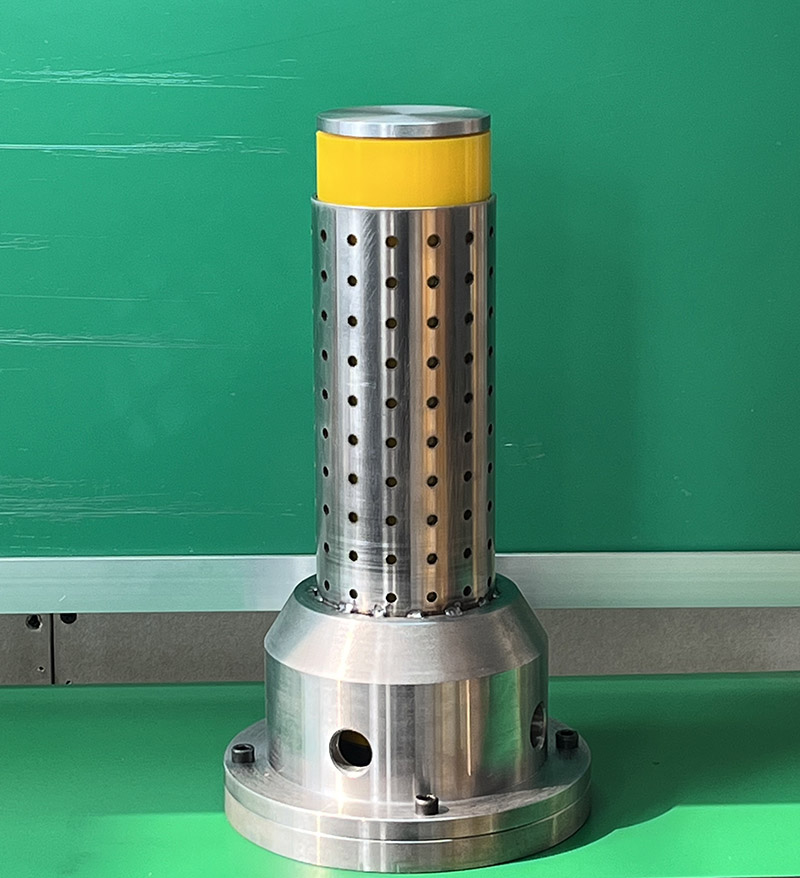

Polyurethane Molds for Powder Metallurgy

Categories: CIP bags, CIP mold

Application: Polyurethane Molds for Powder Metallurgy

InquiryMain description:

Polyurethane Molds for Powder Metallurgy

Polyurethane Molds for Powder Metallurgy

Polyurethane Molds for Powder Metallurgy

Powder metallurgy press pressing is the process of compacting the powder in the mold or other containers into a predetermined shape and size compact under the action of external forces. The powder is loaded into the negative mold and pressed through the upper and lower die punch. In the compression process, with the movement and deformation of the powder, a large void is filled, the oxide film on the surface of the particles is broken, and the contact area between the particles is increased, so that the attraction between the atoms and the mechanical wedge cooperation between the particles is enhanced, thus forming a compact with a certain density and strength.

The pressure directly acts on the powder body or the elastic die sleeve, so that the powder body is evenly compressed in all directions at the same time to obtain a compact with uniform density distribution and high strength. According to its characteristics, it is divided into two categories: cold isostatic pressing and hot isostatic pressing.

In powder metallurgy, the choice of die for isostatic pressing is very important. Elastomer mold, not only to ensure good molding, less processing allowance, high quality of finished products, but also durable, long service life. After a long time comparison, in the elastomer mold, the special imported polyurethane isostatic pressure mold has obvious advantages in all aspects of performance.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com