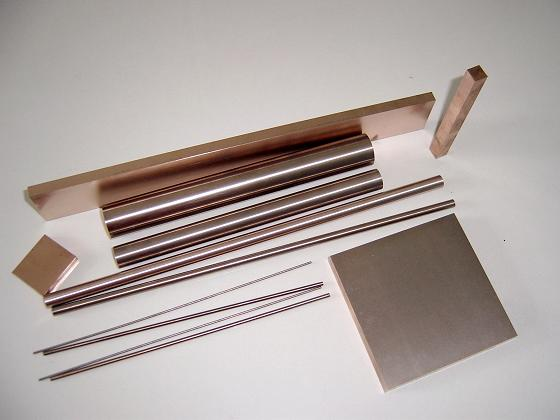

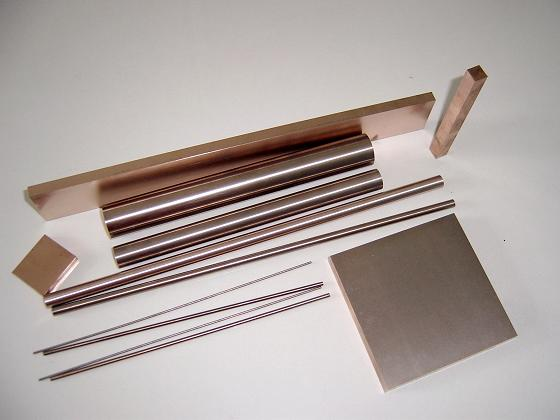

Cold Isostatic Pressing Molds for Tungsten Copper Powder

As opposed to the hot isostatic pressing HIP (Hot Isostatic Pressing) process, there is also the cold isostatic pressing CIP (Cold Isostatic Pressing) process, which generally applies uniform pressure to the material sealed in the plastic mold at room temperature in all directions at the same time. , It is mostly used for the molding of powdered metal or non-metallic materials, and provides pre-compacts for subsequent sintering. Tungsten-copper alloy is a pseudo-alloy composed of two metals, W and Cu, which are incompatible with each other and have large differences in physical and chemical properties. It is difficult to prepare by conventional methods, and it must be prepared by powder metallurgy PM process. According to the different pressure transmission liquid, cold isostatic pressing includes wet bag method and dry bag method isostatic pressing and soft mold pressing. Due to the friction between the powder and the powder, between the powder and the die punch and the die wall in the conventional die compaction method, the distribution and transmission of the force during the compaction process will be changed to a certain extent, and at the same time, the density and strength distribution of each part of the compact will be different. In contrast, the forming pressure of the cold isostatic pressing process is more uniform, which can ensure that the green compact has a uniform density and a complete shape under a lower pressure, and the mold loss is small and the forming efficiency is high.

In addition, it should be noted that controlling the pressing speed in the process of cold isostatic pressing is also an important factor affecting the density of the green compact. It affects not only the state of friction between the powder particles and the degree of work hardening, but also the gas evolution. If the pressurization speed is too fast, the gas is not easy to escape, and the gas remaining in the billet is relatively large, and correspondingly difficult to eliminate pores or pores will be left in the subsequent sintering process. In addition, if the pressing speed is too fast, a large internal stress will be accumulated inside the powder, which will lead to elastic aftereffects on the green compact after the pressure is released. Therefore, reducing the pressing speed and appropriately extending the holding time during the pressing process can make the pressure transfer sufficient, and the air between the powders has sufficient time to escape, which is beneficial to the density distribution of the green compact and effectively avoids elastic aftereffects.

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

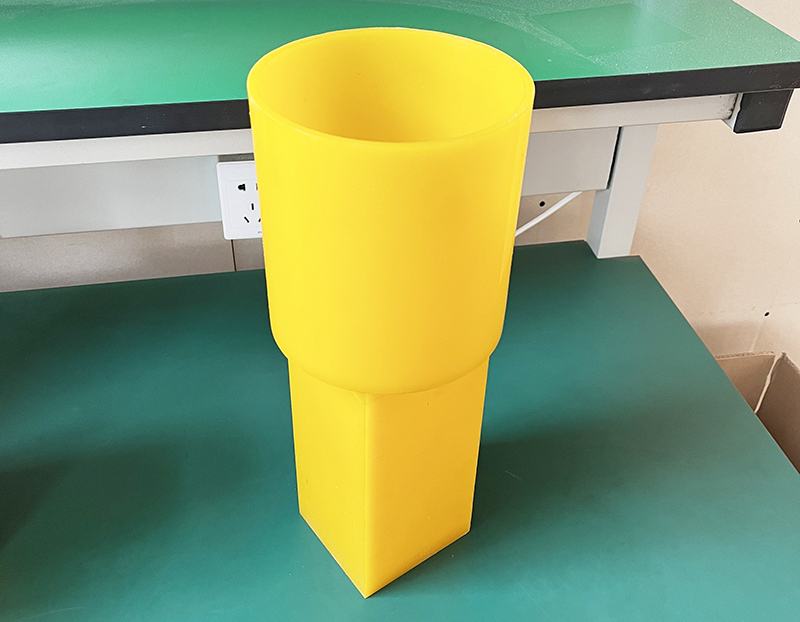

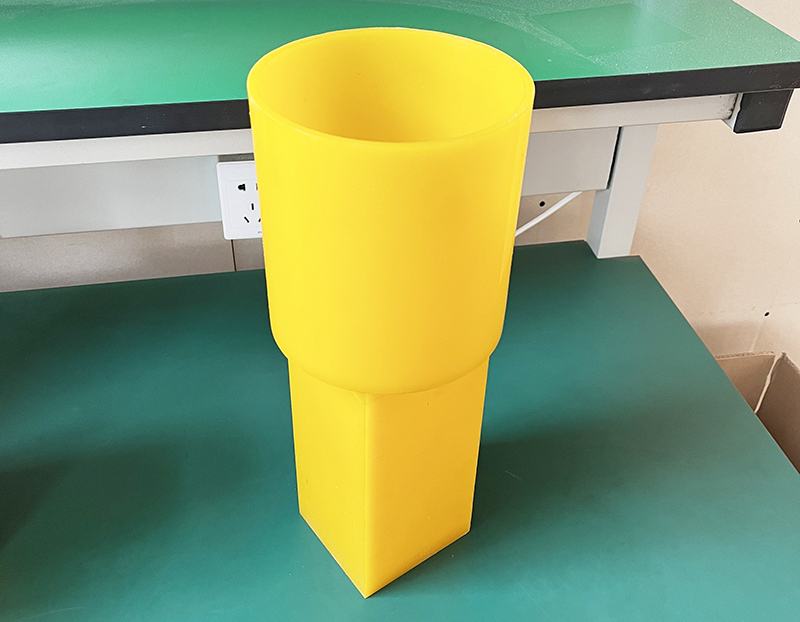

Product overview: Isostatic pressing rubber mold is used for the molding of ceramic materials, tungsten and molybdenum materials, graphite materials, refractory materials, and alloy powders. It can be customized according to drawings, and can be designed according to samples.

Product features: The deformation of the elastic mold under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the blank is uniformly stressed, and the density distribution is uniform, and the pre-pressed blank is encapsulated. In the elastic rubber mold, it is put into the high-pressure cylinder after sealing, and the green body is compressed and formed by liquid transfer.

Product advantages: The design of the mold cover is reasonable to ensure no water leakage, the blank is well formed, and the service life is long, including the fixture for processing the blank, which can be customized! There is a free amount of open steel molds.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold