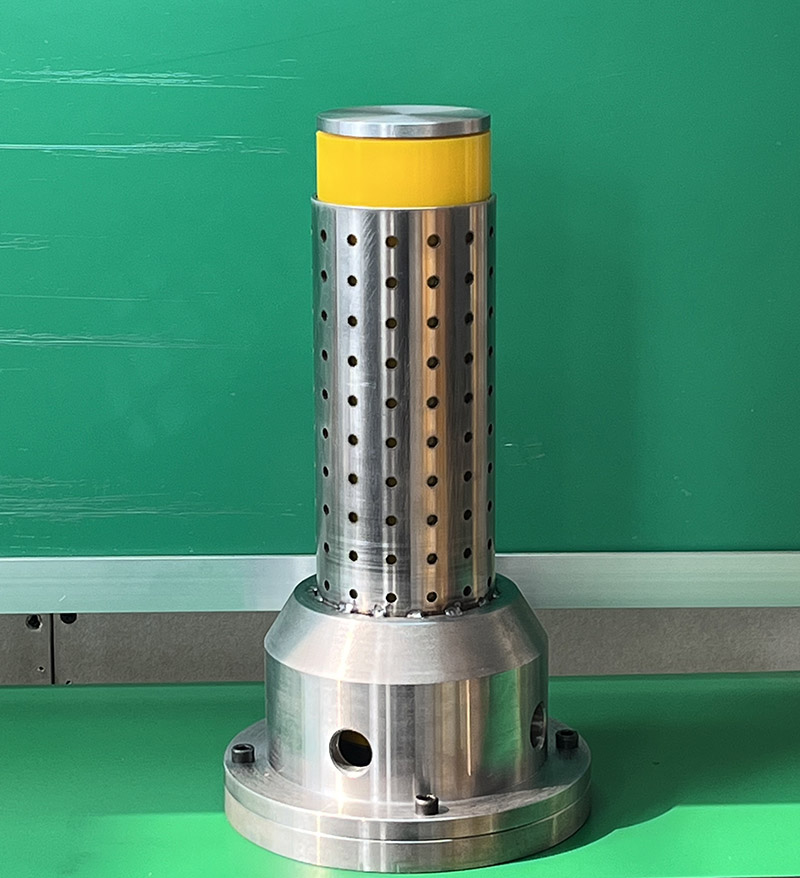

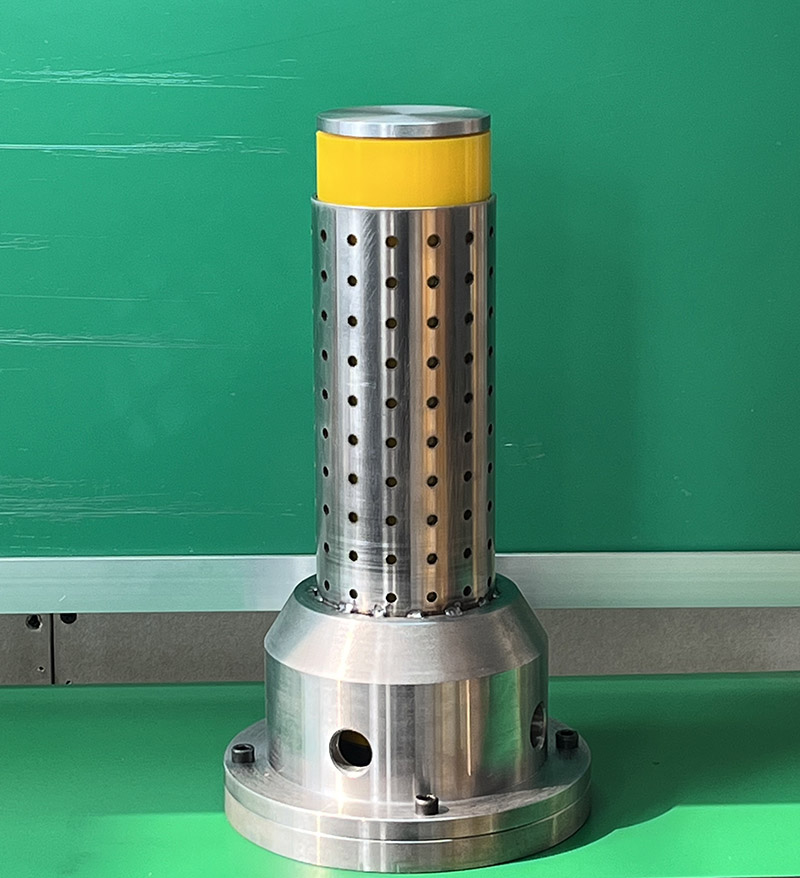

Isostatic Pressing Molds for Powder Metallurgy

Powder metallurgy compression molding machine is to fill the mold with powder relying on gravity, and extrude it through hydraulic press pressure. It is the most widely used type in actual industrial applications. Warm pressing belongs to pressing forming, which can realize two-way pressing and forming, and complex structural parts can be produced.

Powder pressing, a powder forming method that uses external pressure in a die. Also known as powder compression molding. The press forming process consists of powder loading, pressing and demoulding. The content of powder compaction includes four aspects: powder compaction theory, powder compact, powder compaction mold and powder compaction press.

Powder metallurgy molding is one of the basic processes in powder metallurgy production, the purpose is to make loose powder into semi-finished or finished products with predetermined geometry, size, density and strength. Powder metallurgy molding technology is a processing method that uses a mixture of metal powder and compound powder as raw materials, and undergoes molding and sintering operations to prepare metal oxide materials and their composite materials.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold