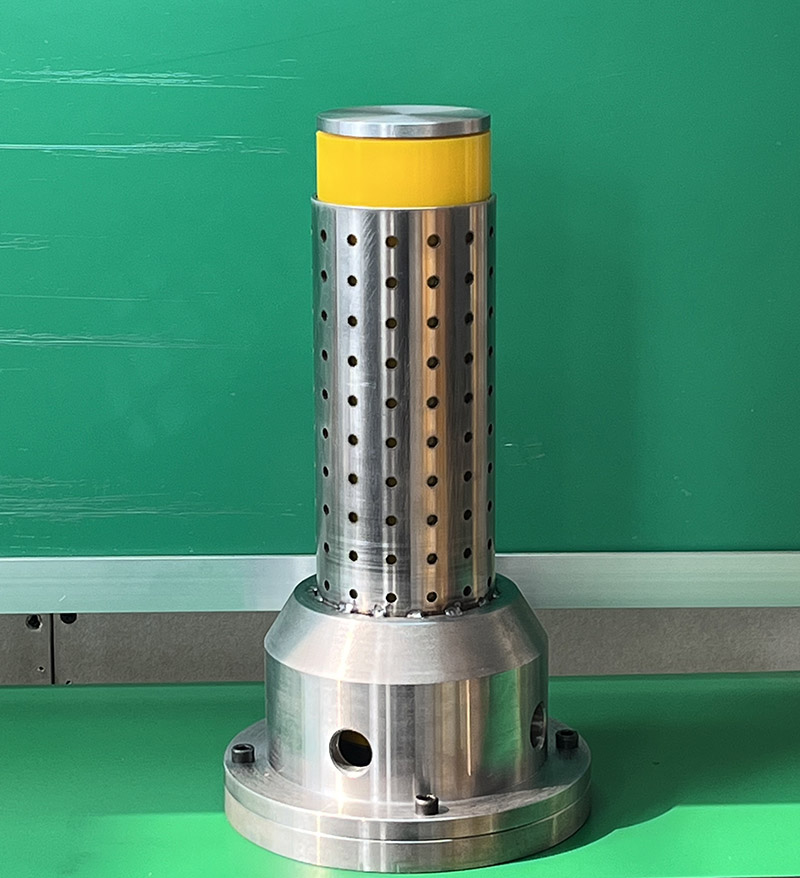

Cold Isostatic Pressing Molds for Alumina Ceramic Balls

Categories: Cold isostatic pressing mold

Application: Cold Isostatic Pressing Molds for Alumina Ceramic Balls

InquiryMain description:

Cold Isostatic Pressing Molds for Alumina Ceramic Balls

Cold Isostatic Pressing Molds for Alumina Ceramic Balls

Cold Isostatic Pressing Molds for Alumina Ceramic Balls

The cold isostatic pressing process can apply higher pressures to ceramic or metal powders, up to 100-600 MPa at room temperature or slightly higher temperatures (<93°C), to obtain "green" parts with sufficient strength for processing and machined and sintered to ultimate strength. Hot and cold isostatic pressing technologies allow ceramic manufacturers to increase productivity while controlling material properties.

Common applications for cold isostatic pressing include the consolidation of ceramic powders, graphite, refractories, electrical insulators, and the compression of advanced ceramics. Materials include silicon nitride, silicon carbide, boron nitride, boron carbide, titanium boride, spinel, etc. The technology is expanding into new application areas such as the pressing of sputtering targets, the coating of valve components in engines to reduce cylinder wear, telecommunications, electronics, aerospace and the automotive sector.

Cold isostatic pressing technology has the following advantages: improve the degree of consolidation of the product, increase the mechanical properties of the product, relatively centralized data in the production process, can control production more safely, very low corrosion, high efficiency and low cost. The decompression process in the cold isostatic pressing process also determines the quality of the "green" compact. As the metal or ceramic powder is compacted, gas is trapped between the particles, and the pressure increases during processing as externally applied pressure increases. Metal compacts are very strong and ductile and will naturally release entrapped air after the cold isostatic pressing process.

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

Product overview: Isostatic pressing rubber mold is used for the molding of ceramic materials, tungsten and molybdenum materials, graphite materials, refractory materials, and alloy powders. It can be customized according to drawings, and can be designed according to samples.

Product features: The deformation of the elastic mold under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the blank is uniformly stressed, and the density distribution is uniform, and the pre-pressed blank is encapsulated. In the elastic rubber mold, it is put into the high-pressure cylinder after sealing, and the green body is compressed and formed by liquid transfer.

Product advantages: The design of the mold cover is reasonable to ensure no water leakage, the blank is well formed, and the service life is long, including the fixture for processing the blank, which can be customized! There is a free amount of open steel molds.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com