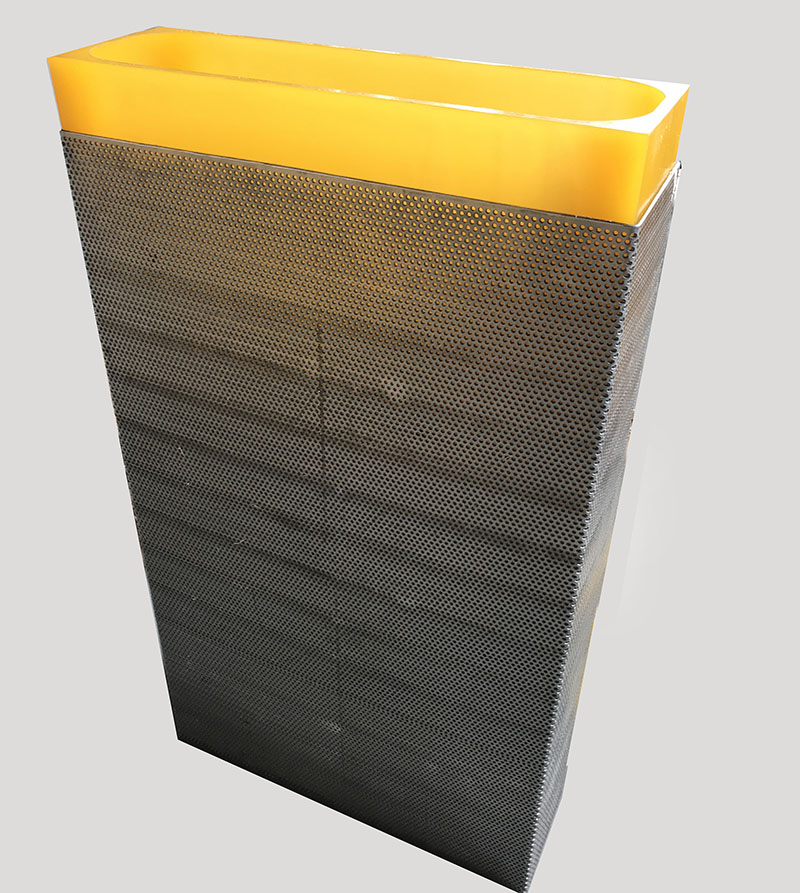

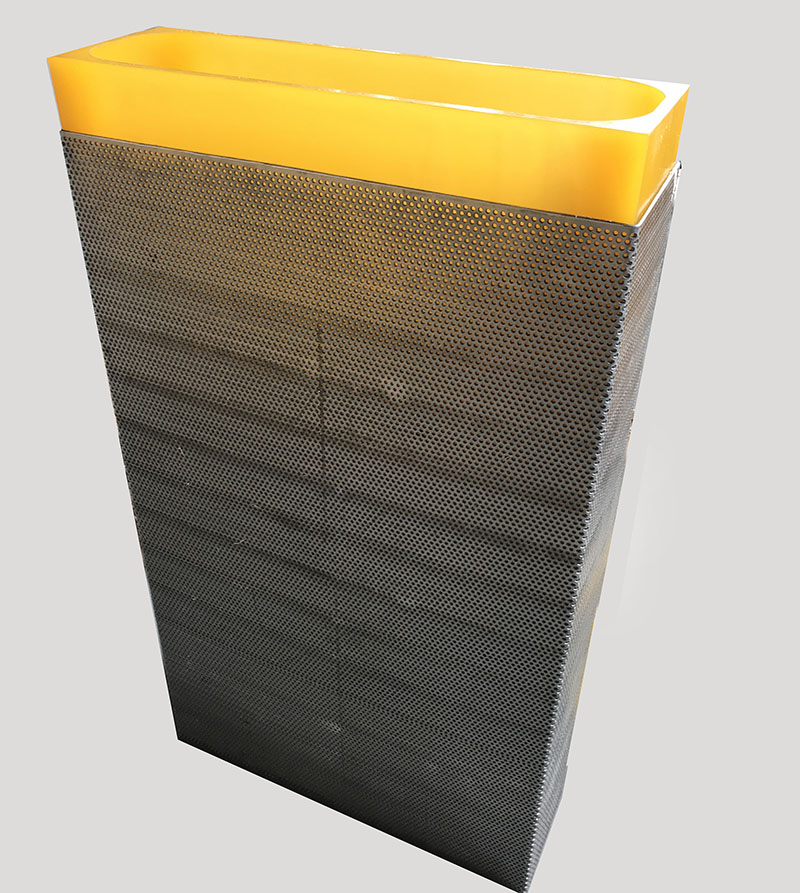

Isostatic Pressing Molds for Powder Metallurgy Molding

Categories: Isopressing mold

Application: Isostatic Pressing Molds for Powder Metallurgy Molding

InquiryMain description:

Isostatic Pressing Molds for Powder Metallurgy Molding

Isostatic Pressing Molds for Powder Metallurgy Molding

Isostatic Pressing Molds for Powder Metallurgy Molding

1. Isostatic pressing

Cold isostatic pressing CIP: At room temperature, rubber or plastic is usually used as the jacket mold material, and liquid is used as the pressure medium. It is mainly used for powder material molding, and provides green bodies for further sintering, forging or hot isostatic pressing processes. Hot isostatic pressing (HIP): Under the action of high temperature and high pressure at the same time, the material is subjected to isostatic pressing. It is not only used for the consolidation of powder, but also completes the two steps of forming and sintering in the traditional powder metallurgy process. It is used for the diffusion bonding of workpieces, the elimination of casting defects, and the production of complex-shaped parts.

2. Continuous powder forming

The process in which the powder changes continuously from a loose state to a compact or product with a certain density, strength and desired size and shape under the action of pressure. It mainly includes powder rolling, extrusion, spray forming, wedge pressing, etc.

3. Powder injection molding

Using the principle of plastic injection molding, the metal powder (ceramic powder, etc.) and organic binder are made into a mixture. On the injection molding machine, it is injected into the closed mold through the injection port under a certain temperature and pressure, and the mold is opened after cooling. Get the green body.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com