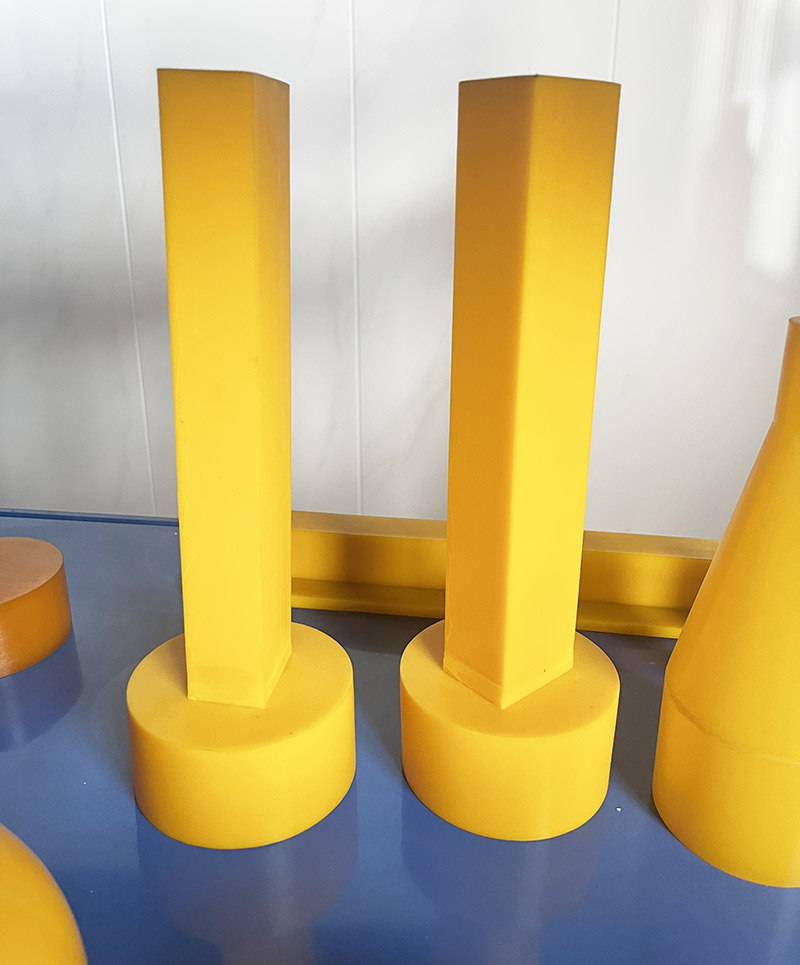

ISO Mold/CIP Mold (Dry-bag Isostatic Pressing and Wet-bag Isostatic Pressing)

Isostatic pressing

(1) Definition and classification of isostatic pressing

Definition: The powder is installed in an elastic (flexible) mold (cover), with fluid as the pressure transmission medium, and is uniformly pressed in all directions.

(2) General characteristics of isostatic pressing

The shape and size range of the green compact is large, especially the large size and complex shape crushed or finished products;

The density of the green compact is high and uniform;

Wide range of forming powders, especially refractory metal compounds, ceramics, high-alloy steel, etc.

The process is simple and no lubricant is required

Cold isostatic pressing CIP

1. Definition: At room temperature, the powder is placed in an elastic mold, and the liquid is used as the pressure transmission medium, so that the powder is uniformly pressed in all directions and compacted into a green compact.

2. Principle of cold isostatic pressing:

Press the fluid medium into a high-pressure resistant steel airtight container by means of a high-pressure pump—the static pressure of the high-pressure fluid directly acts on the powder in the elastic mold sleeve;

According to Pascal's principle, the powder body is subjected to approximately equal pressure in all directions;

Eliminates the external friction between the powder and the die sleeve - the pressure required to achieve the same density is lower than that of molding

1. Wet bag cold isostatic pressing

The package containing the powder is placed in a perforated metal sleeve, and is directly placed in the pressure transmission medium of the high-pressure vessel for isostatic pressing.

2. Dry bag cold isostatic pressing

The powder is packed in a forming sheath, and then placed in a pressurized sheath fixed in a high-pressure container for cold isostatic pressing.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold