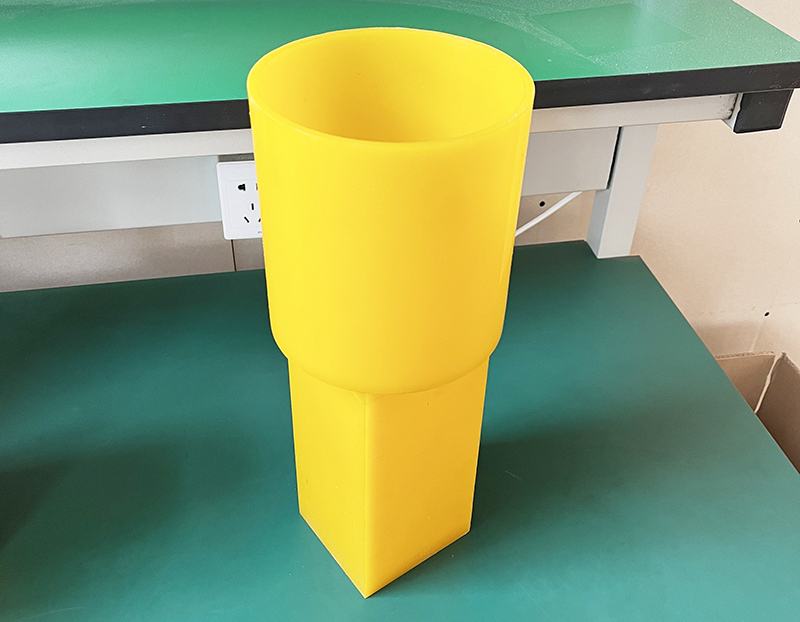

Isostatic Pressing Mold for Refratory

Categories: Powder metallurgy bag mold

Application: Isostatic Pressing Mold for Refratory

InquiryMain description:

Isostatic Pressing Mold for Refratory

Isostatic Pressing Mold for Refratory

Isostatic Pressing Mold for Refratory

Refractory Forming

1. What is molding? Why do molding?

With the help of external force and models, the process of processing mud (or mixture) suitable for a certain molding operation into a green body or product with a certain shape, size and strength is called molding. However, the construction of the newly developed self-flowing castable basically does not require external force.

Forming is firstly to meet the use requirements of the product. When building refractory materials, the product is required to have a certain shape, precise size and sufficient strength. Secondly, molding is also an effective means to improve the physical and chemical properties of products, and the organizational structure of products can be improved through molding. In addition, forming is also a requirement of the post-production process of refractory materials, such as handling, drying, and firing, and especially has a great impact on the way of laying bricks during firing.

2. What are the commonly used molding methods? How to choose a suitable molding method?

There are many molding methods for refractory materials, and the commonly used molding methods include backlog molding, vibration molding, extrusion molding, ramming molding, isostatic pressing molding, melting casting molding, and grouting molding.

Which forming method to choose is mainly based on the properties of the mud, the shape, size and other process requirements of the green body. Except that most refractory materials are formed by machine pressing, vibration forming is generally used to form large special-shaped blanks, extrusion molding is generally used for forming tubular blanks, and grouting molding is generally used for forming hollow thin-walled blanks. Isostatic pressing is currently used in the production of high-performance refractory materials.

3. What are the characteristics of isostatic pressing? Which products are suitable for molding?

The method of applying equal pressure to the mud in all directions is called isostatic pressing. Commonly used pressure transmission medium is liquid, such as oil, water or glycerin. Because the compressibility of brake fluid or anhydrous glycerin is extremely small, almost all the pressure can be transmitted to the spring mold, so these two liquids are often used as pressure transmission medium.

The biggest feature of isostatic pressing is that each part of the mud is pressed evenly and at a high pressure, so that the density of the green body obtained in this way is high and uniform, so that the deformation and shrinkage of the green body during the firing process are greatly reduced. There will be no firing cracks caused by the stress generated by the density difference of the green body formed by the general forming method. In addition, the pressurization operation of isostatic pressing is simple, and the molding pressure is easy to adjust; the rubber or plastic molds for molding are easy to manufacture, low in cost, and can be used repeatedly; no or less temporary binders can be used in the mud.

Isostatic pressing can be used to press large and slender products with complex shapes that are difficult to form by general molding methods. Such as long nozzle, submerged nozzle, tuyere brick, integral stopper, etc.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com