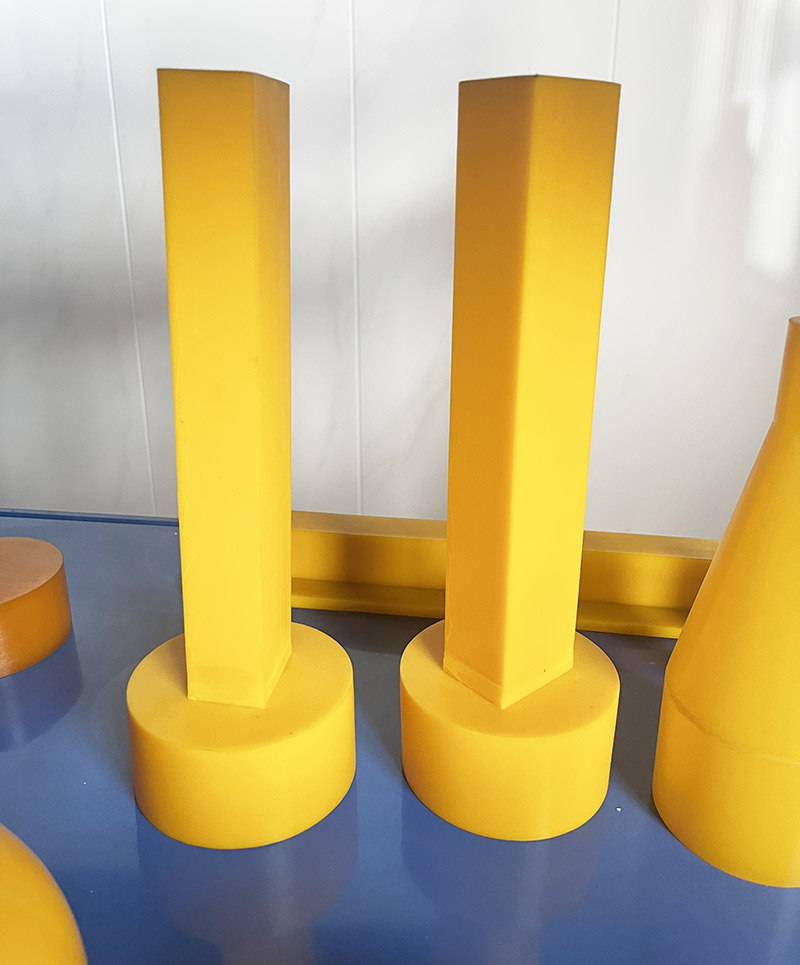

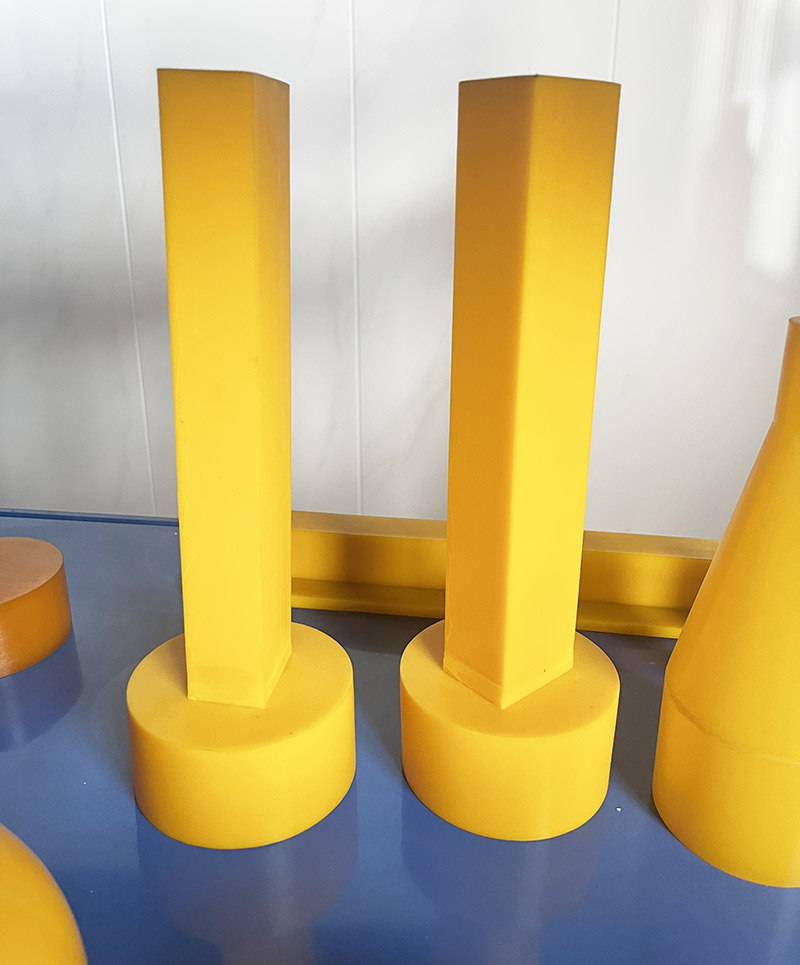

Isostatic Pressing Molds for Powder Metallurgy

Powder metallurgy

Powder metallurgy is a process technology for producing metal powder or using metal powder (or a mixture of metal powder and non-metal powder) as raw material, forming and sintering to manufacture metal materials, composite materials and various types of products. The powder metallurgy method has similarities with the production of ceramics, and both belong to the powder sintering technology.

Cold isostatic pressing

The cold isostatic press is to place the material in a sealed and elastic mold into a container containing liquid or gas, and apply a certain pressure with liquid or gas to press the material into a solid body to obtain the original shape of the blank body. After the pressure is released, the mold is taken out from the container, and after demoulding, the green body is further shaped as required.

Therefore, the role played by the mold is very important. It must be resistant to high pressure, tear resistance, good resilience, small deformation, easy demoulding, easy processing, and low cost.

Isostatic pressing mold

The powder is subjected to equal hydrostatic pressure in all directions. The liquid is used as the pressure transmission medium. The powder is loaded into an elastic mold and pressurized in a high-pressure cylinder. The isostatic press consists of a high-pressure container and a high-pressure oil pump. The high-pressure vessel is made of high-grade alloy steel and has a certain thickness. to withstand enormous pressure. The size of the container is selected according to the size of the molded product. The liquid medium in the high pressure vessel can be oil, water or glycerin etc. Generally, brake fluid or anhydrous glycerin are used. The compressibility of these two liquids is extremely small, and almost all the pressure can be transmitted to the elastic mold.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold