Cold Isostatic Pressing Molds/Bags

Cold isostatic pressure techniques use a liquid medium, such as water or oil or glycol mixtures, to apply pressure to the powder. The powder is placed in a fixed shape mold that prevents the liquid from penetrating the powder. For metals, the cold isostatic pressing technique can achieve a theoretical density of about 100%, while more difficult to compress ceramic powders can achieve a theoretical density of about 95%.

Very high pressures cause the voidage in the powder to become smaller or even disappear. At high pressures, metal powders deform due to their malleability, while ceramic powders may break slightly, allowing their density to increase, resulting in "green" parts that can be handled, machined, and sintered. The typical pressure range is 100-600MPa, and the temperature is usually room temperature. If higher temperatures are required, the heat exchanger can raise the temperature to about 93 ° C. However, since the temperature of water increases as it is compressed, about 4 ° C for every 100MPa increase, the risk of boiling at higher temperatures increases.

Common applications of cold isostatic pressing include consolidation of ceramic powders, graphite, refractories, electrical insulators, and compression of advanced ceramics. Materials include silicon nitride, silicon carbide, boron nitride, boron carbide, titanium boride, spinel and so on. The technology is expanding into new applications, such as sputtering target pressing, coating valve parts used to reduce cylinder wear in engines, telecommunications, electronics, aerospace and automotive.

Cold isostatic pressing technology has the following advantages: improve the degree of consolidation of products, increase the mechanical properties of products, relatively centralized production data, more safe control of production, very low corrosion, high efficiency and low cost.

The decompression process in the cold isostatic pressing process also determines the quality of the "green" block. As the metal or ceramic powder is compacted, the gas is trapped between the particles, and the pressure increases as externally applied pressure increases during processing. The metal block is very strong and malleable, and will naturally release the entrapped air after a cold isostatic pressure process.

Cold isostatic pressing technology is widely used in domestic ceramics, architectural ceramics, special ceramics and other fields. For example, plate, plate, alumina grinding ball, alumina chemical packing ball, firebrick, ceramic stick, spark plug, high frequency porcelain bushing, composite ceramics, etc.

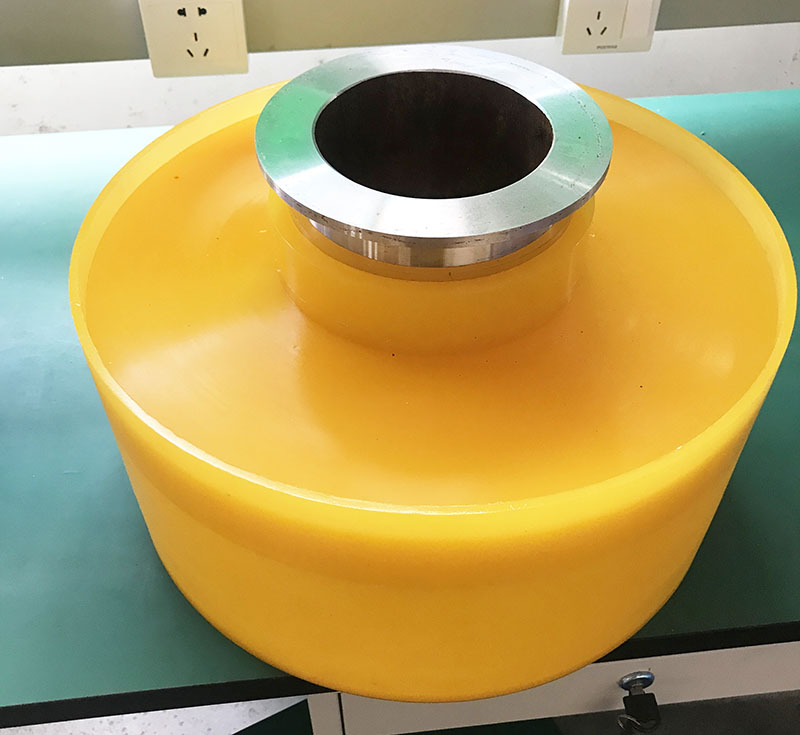

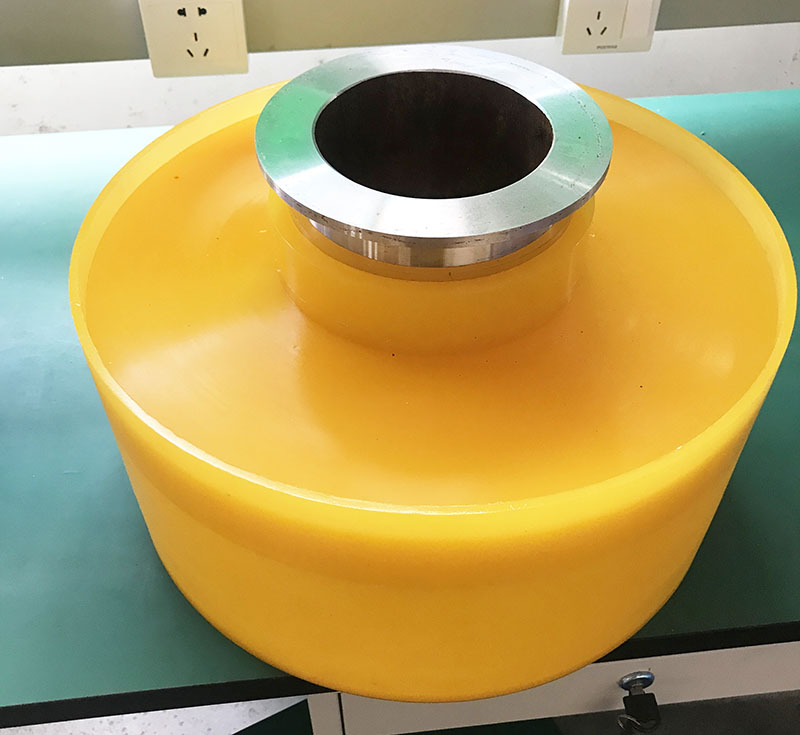

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold