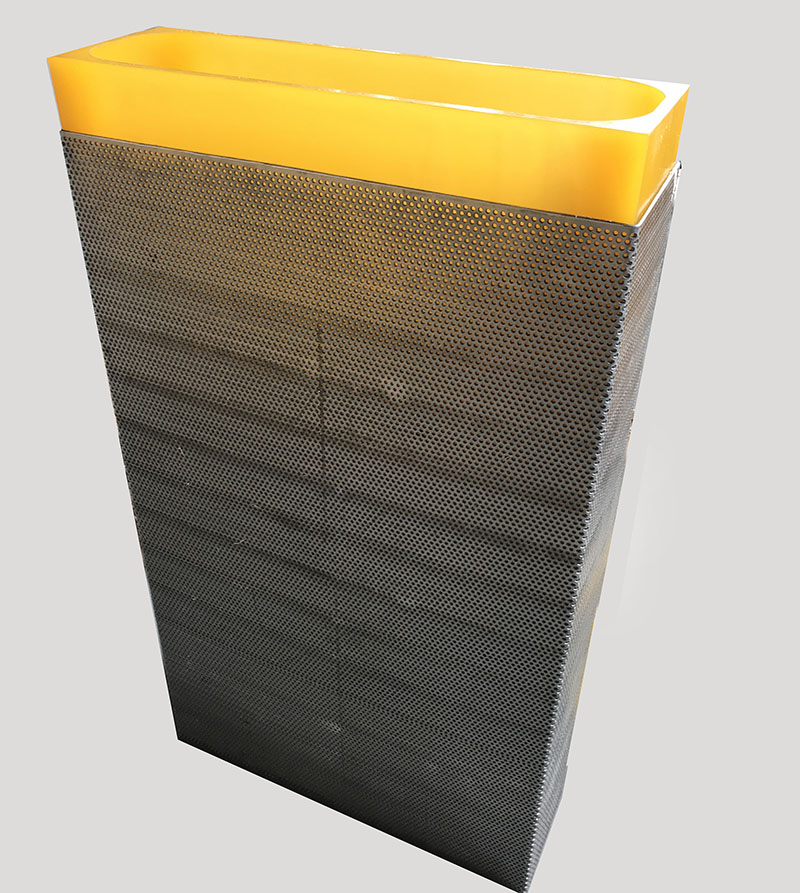

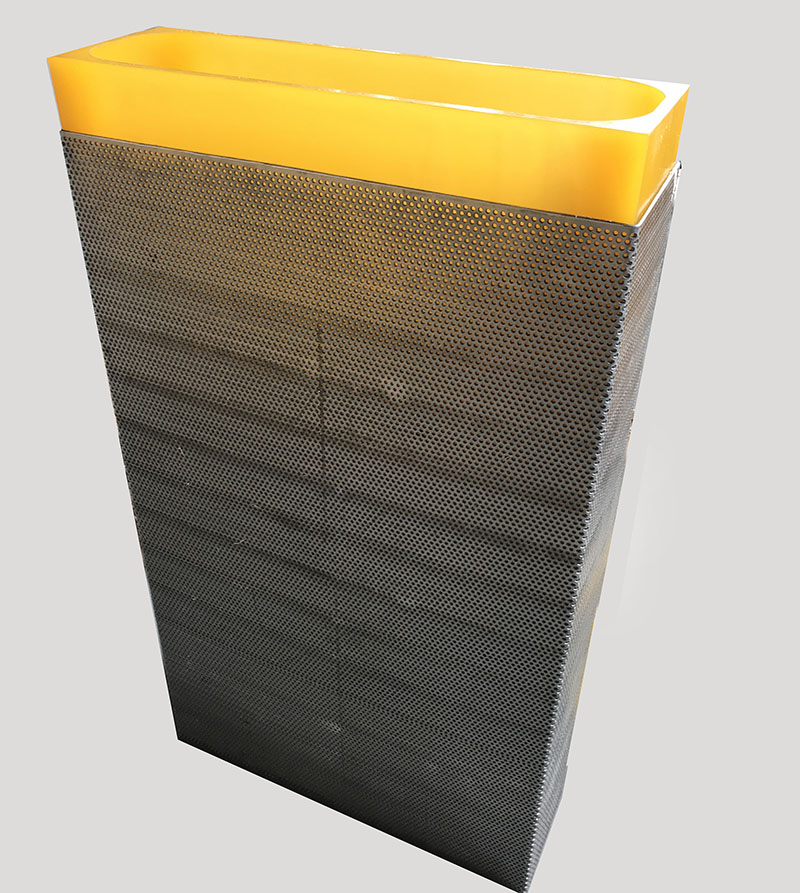

Dry-bag Isostatic Pressing Molds

Cold isostatic pressure principle: isostatic pressure technology is a kind of powder molding process using closed high pressure container products, it applies the same pressure to powder blank in all directions, so that the powder products have the most uniform density distribution and grain structure. This process is mainly used for simple or complex shaped parts requiring uniform strength and fracture resistance, but also can manufacture powder metallurgy products with large length-diameter ratio.

Cold isostatic pressing: Cold isostatic pressing is a kind of powder forming equipment under ultra-high pressure. Usually rubber or plastic is used as the mold covering material, liquid is used as the pressure transmission medium, and the same pressure is applied to the powder blank in all directions to press into a predetermined shape, so as to provide blank for the next sintering, forging or hot isostatic pressing process.

Dry bag isostatic pressure has the advantages of high automation, high production efficiency, stable product quality, suitable for large-scale industrial production, and can avoid the pollution of the working medium.

Applications of cold isostatic pressure

Cold isostatic pressing is widely used in a wide range of industries such as hard alloy, powder metallurgy, high speed steel, titanium and titanium alloy, refractory materials, graphite, crucible, ceramics, rare earth permanent magnet, crystal, medicine and food because it can make powder raw materials with high density and excellent material homogeneity. Cold isostatic pressing machine is very conducive to machining, but also can produce a variety of particularly complex shapes of products.

Isostatic press according to PASCAL's principle, used for all kinds of powder products in ultra-high pressure molding, the finished products of good anisotropic identity, for high performance requirements, complex shape and slender ratio of large parts have a good effect. Isostatic pressure works according to PASCAL's law: "The pressure of a medium (liquid or gas) in a closed container can be transmitted equally in all directions.

The difference between dry bag isostatic pressure and ordinary isostatic pressure is that it receives the pressure of the working medium of the isostatic high pressure chamber across the dry bag. Usually, the mold is fixed in the dry bag (or the dry bag is directly used as the mold). The lip of the dry bag is close to the inner wall of the high pressure chamber and the high pressure chamber to form a closed space. The pressure is transferred to the rubber mold around the dry bag, and the powder to be pressed is filled in the mold cavity. The working medium in the high pressure cavity can press the required workpiece.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold