Powder Metallurgy Cold Isostatic Pressing Molds

Categories: CIP bags, CIP mold

Application: Powder Metallurgy Cold Isostatic Pressing Molds

InquiryMain description:

Powder Metallurgy Cold Isostatic Pressing Molds

Powder Metallurgy Cold Isostatic Pressing Molds

Powder Metallurgy Cold Isostatic Pressing Molds

What are the techniques of powder metallurgy?

1. PM Technology:

In traditional powder metallurgy, or PM, metal powder is compacting under a sophisticated custom mold, known as a billet, and then the parts are heated to a temperature below the melting point of the metal.

2. Hot melt technology:

Powder injection molding production of highly complex shapes and relatively small parts generally use conventional injection molding machine below 250 grams, and then through heat or solvent treatment, remove most of the adhesive, binder residue removal, sintering, get the final size.

3. Hot isostatic pressure technology:

When metal powders are used to make very large and complex shapes, this is a technique called hot isostatic pressing, in which the product is placed in a closed container, where equal pressure is applied to the product, and high temperature is applied at the same time. Under the action of high temperature and high pressure, the product is sintered and densified.

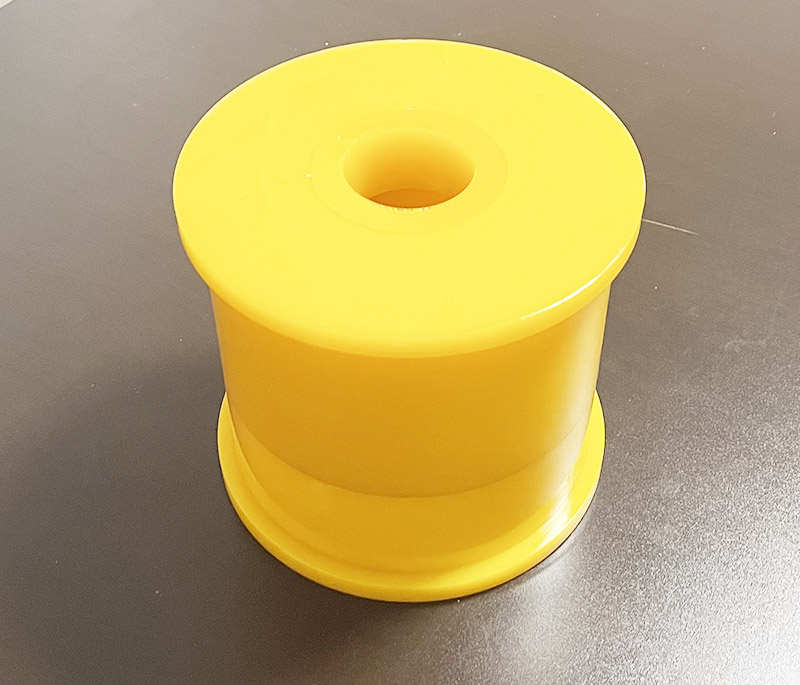

4. Cold isostatic pressure technology:

In the definition of powder metallurgy also includes other technologies, there are cold isostatic pressure, that is, at room temperature, usually with rubber or plastic as a casing mold material, with liquid as the pressure medium, mainly used for powder material molding, for further sintering. There is what is called calendering, which produces continuous strips or sheets, resulting in a variety of flat and thin final products, billet tubes and sheets.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

Polyurethane Products Pu Products Rubber Mold Plastic Mold