Cold Isostatic Pressing Technology

Cold isostatic pressing technology is a technology that realizes isostatic pressing at room temperature. Usually, rubber or plastic is used as the mold material for the sheath, and liquid or elastomer (plastic, rubber) is used as the pressure medium, and the pressure can reach 600MPa. Cold isostatic pressing technology overcomes the disadvantages of shape distortion caused by common molding technology, so that the cold isostatic pressing compact has high and uniform density, small shrinkage, and easy control of shape. Expand to other powder metallurgy fields. Since the size of the compact formed by the cold isostatic pressing process is only limited by the size of the inner cavity of the high-pressure cylinder, it does not need to be controlled by the total pressure of the ordinary molding press, so the cold isostatic pressing technology can be used to form large-sized compacts. The compact shape compact can be formed by cold isostatic pressing technology through the mold cavity of the plastic sheath or the mold cavity formed by the rigid mold.

Application in powder metallurgy

Cold isostatic pressing technology is widely used to manufacture hard alloy rolls with large size, complex shape and strict performance requirements, anvils for artificial diamond, hard alloy tools, etc. It is also widely used to form various powder materials with large aspect ratio, such as tungsten, high-speed steel, beryllium, aluminum and other rod-shaped and tubular blanks of different sizes and shapes, so as to ensure the performance of these materials and give full play to powder metallurgy and cooling. Advantages of combining static pressure technology.

Application of Cold Isostatic Pressing in Ceramics

At present, cold isostatic pressing technology has been applied in the ceramic industry, including refractory bricks, ceramic tubes, alumina lamp tubes, alumina grinding balls, etc.

The most common forming method for ceramics is isostatic pressing.

cold isostatic pressing

The specific method of cold isostatic pressing is to put the powder into a rubber bag, place it in a steel mold, and apply pressure to the powder from all directions to form it. This molding method can evenly apply pressure to the powder, and overcome the disadvantage of insufficient uniform pressure during the dry pressing molding process.

Cold isostatic pressing can be divided into three methods: dry bag method, wet bag method and balanced pressing method. In the dry bag method, the pressurized mold is fixed inside the oil cylinder. This method is easy to operate and has a short cycle, which is suitable for mass production. In the wet bag method, the mold is separated from the pressure cylinder, and this molding method can obtain ceramic green bodies with complex shapes.

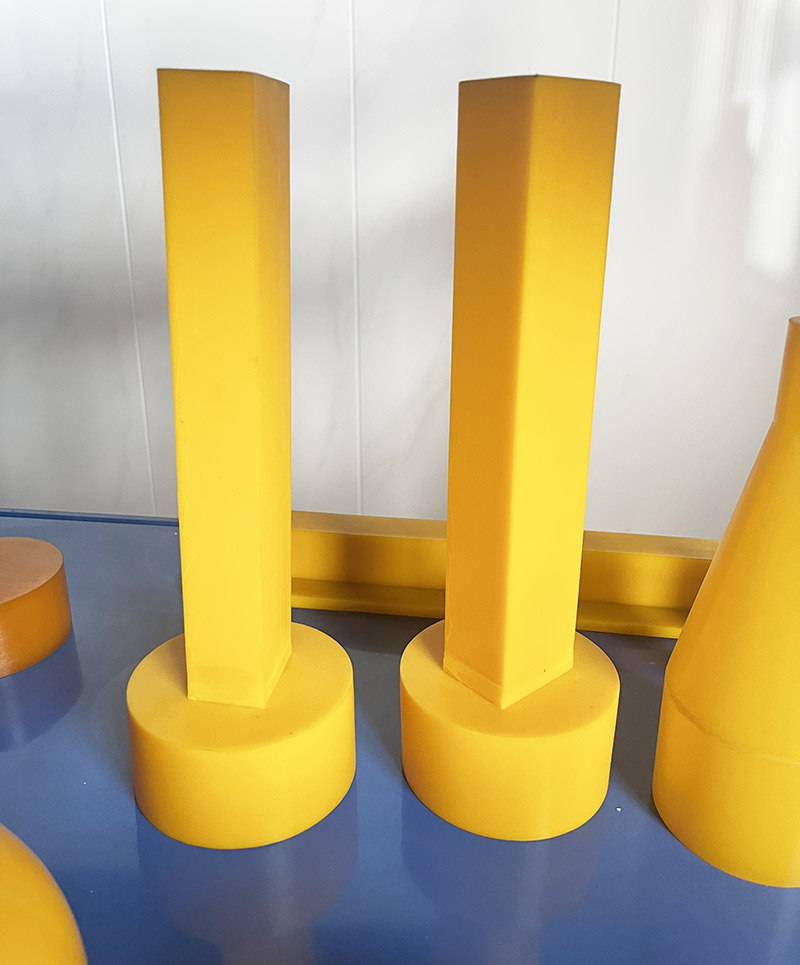

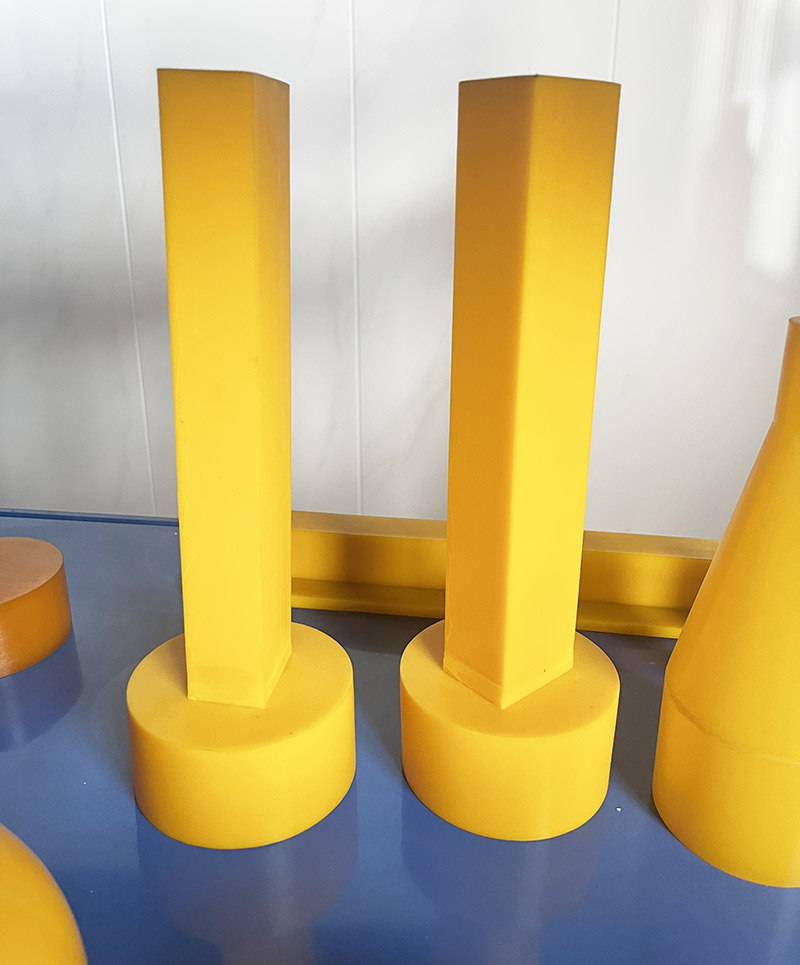

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Polyurethane Products Pu Products