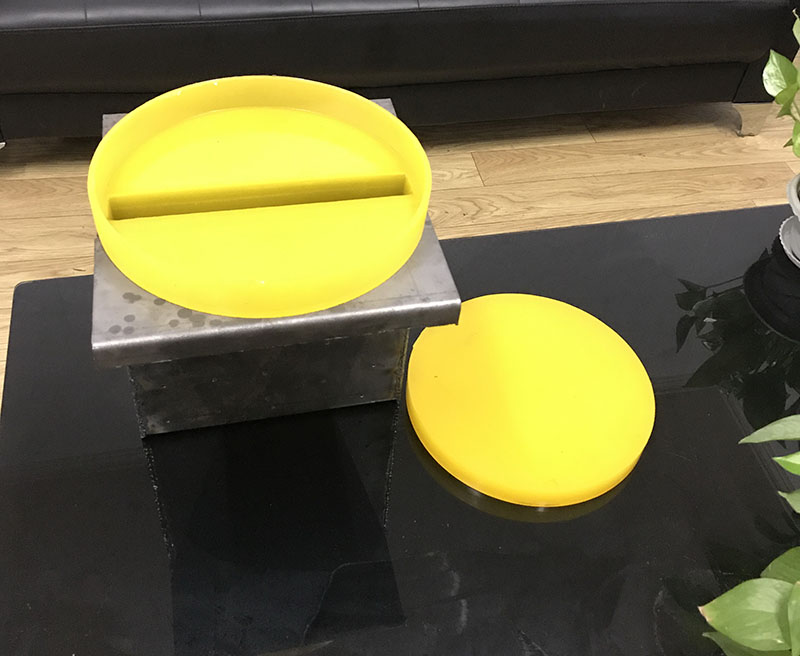

Square CIP bags, square and rectangle cold isostatic press bags mold and tooling

Categories: CIP powder forming bag mold

Application: Square CIP bags, square and rectangle cold isostatic press bags mold and tooling

InquiryMain description:

Square CIP bags, square and rectangle cold isostatic press bags mold and tooling. unmatched performance and can handle the highest pressure and weight loads as well as the fastest cycle times. Extremely long life of the pressure vessel components. Advanced and intelligent pressure control with operator friendly HMI. Fine decompression system for accurate pressure control and possibility to continue the cycle in case of earth fault. The safest and redundant cooling and filter system to handle powder failures. It is THE system for safe operation.