Application and Development Trend of Isostatic Graphite

Categories: Isopressing mold

Application: Application and Development Trend of Isostatic Graphite

InquiryMain description:

Application and Development Trend of Isostatic Graphite

Application and Development Trend of Isostatic Graphite

Application and Development Trend of Isostatic Graphite

(1) Semiconductor industry

Isostatic graphite has good isotropy, excellent thermal conductivity, good resistance to thermal vibration, low coefficient of thermal expansion, high flexural and compressive strength, and can effectively reduce the internal stress caused by rapid cooling and heating of the material, which can extend the service life of equipment or apparatus, so it is used in the field of semiconductor and solar photovoltaic power generation for deep processing of graphite parts for silicon crystal growth equipment, such as graphite crucible, graphite hot field, graphite cover The graphite components for silicon wafer epitaxy, graphite insulation cover and carbon insulation materials are used in the semiconductor and solar photovoltaic fields.

With the rapid development of integrated circuits, the size of silicon crystals developed from 2 inches to 18 inches, the size of graphite crucible used increased, and the technical requirements were strengthened, especially the need for high-purity graphite. So with the development of silicon crystal size technology, graphite parts for silicon growth equipment require graphite crucible, graphite hot field and other materials to high purity, large-scale and high-end technology development.

(2) Electric discharge machining

EDM has the advantages that traditional cutting processing does not have, and can process hard-to-machine materials such as super-hard and high-temperature resistant alloys. At present, about 70% of the electrode materials used in domestic EDM are copper, and about 30% are graphite electrodes. Using isostatic graphite as graphite electrode has some advantages that copper electrode does not have: it does not melt under high temperature and can maintain a certain strength; small electrode consumption during EDM process; fast processing speed; good thermal stability of material during cutting, not easy to deformation; light quality; can ensure the surface quality and dimensional accuracy of processed parts, and the surface is easy to handle.

With the development of science and technology and the demand of actual production processing, EDM is gradually developing towards the precision, microfabrication, high speed and high efficiency of processing, green processing and composite processing. However, in these machining, EDM tool electrode will have serious loss, which will affect the surface quality and dimensional accuracy of the products. Therefore, how to reduce the loss of tool electrode, so as to achieve high-speed, low-loss precision machining is the goal of EDM constantly pursued. Isostatic graphite needs to develop in the direction of finer particles and larger sizes.

(3) Atomic energy industry

(4) Continuous casting industry

Continuous casting crystallizer is an important part of continuous casting equipment, because isostatic graphite has high temperature resistance, corrosion resistance, good electrical and thermal conductivity, oxidation resistance and self-lubricating properties, often used as continuous casting crystallizer. Graphite continuous casting crystallizer has many characteristics that metal continuous casting crystallizer does not have, such as: the work of liquid metal can not leach crystallizer, castings move with the crystallizer friction is small, the production of castings with good surface quality and no reprocessing.

(5) Other applications

Isostatic graphite has a low coefficient of friction and good thermal conductivity, and is often used as bearings, mechanical seals with sealing rings, piston rings and other special engineering materials. In addition, isostatic graphite is also used to make diamond tools, hot field parts for fiber optic wire drawing machines (heaters, holding cylinders, etc.), hot field parts for vacuum heat treatment furnaces (heaters, bearing frames, etc.), and precision graphite heat exchangers.

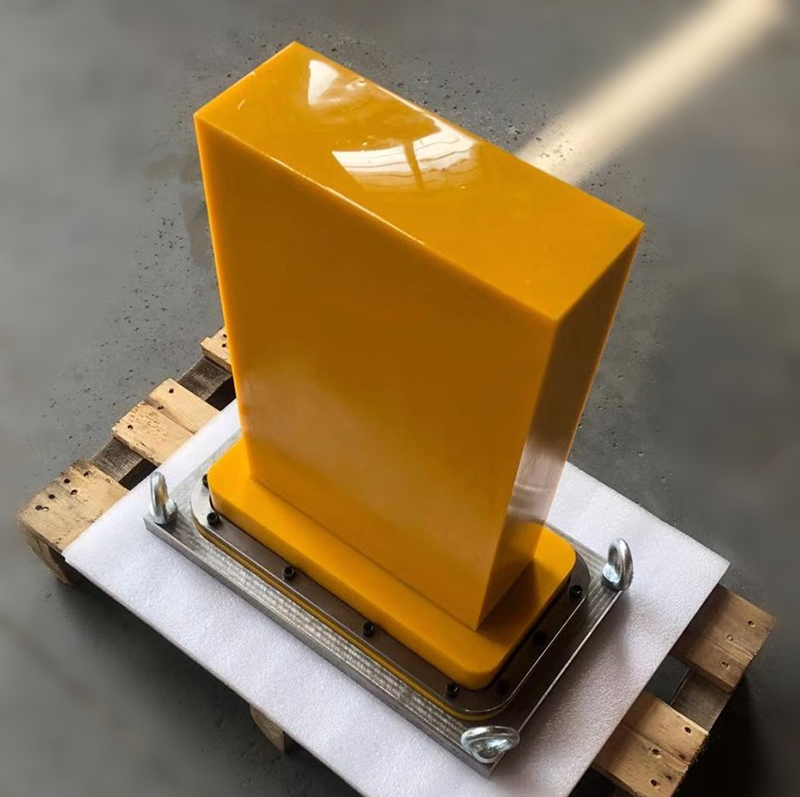

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com